Hot-tek® Hot Access Creation

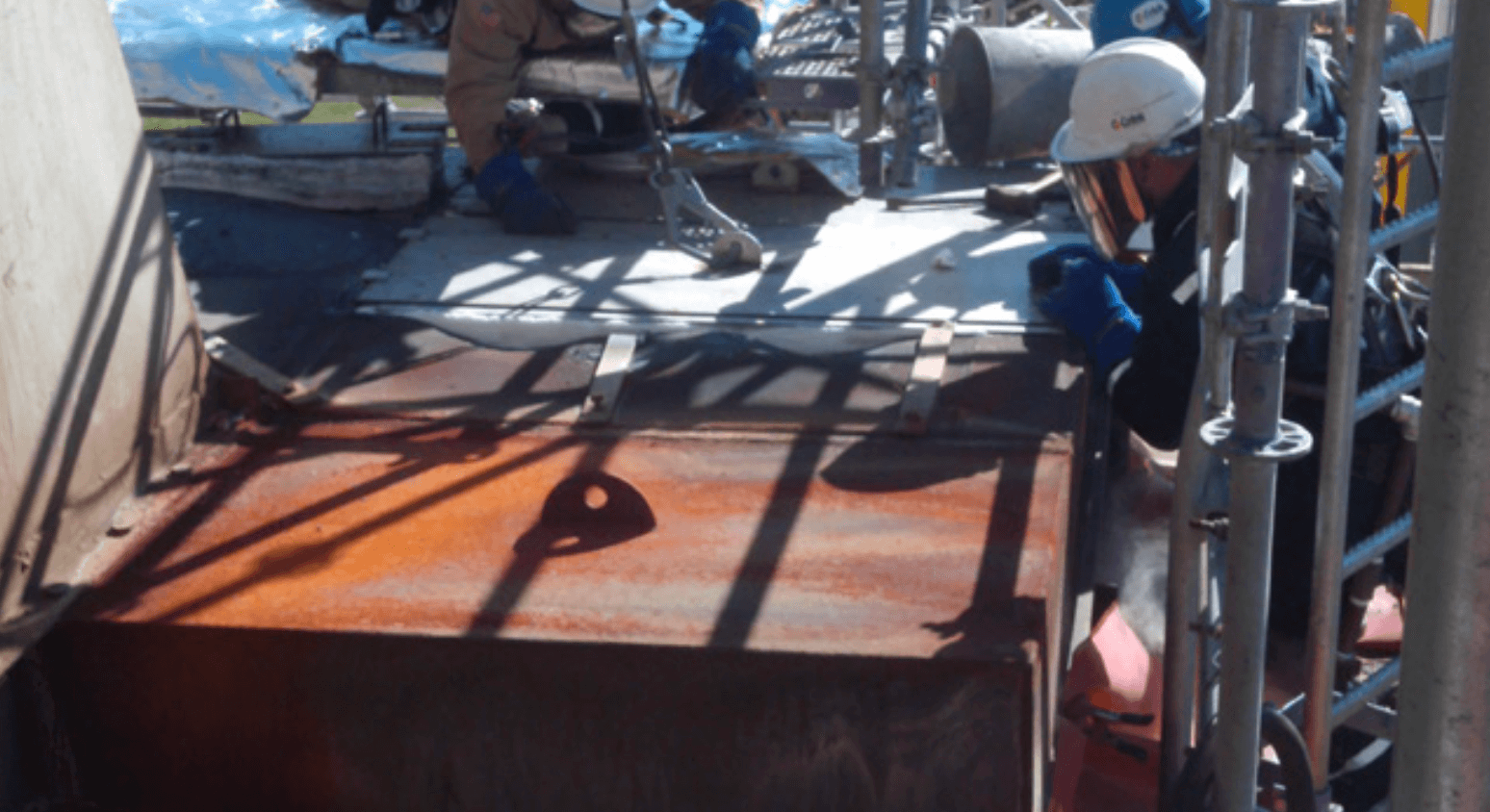

Hot Access Creation enables visual inspection, cleaning, or repair within high-tempereature or pressurized zones – without shutting down the unit.

When fired heater or process unit issues arise, operators often need internal visibility or intervention, but many assets lack adequate access points. The Hot-tek® Hot Access Creation service provides a controlled, engineered method to create reusable access ports online, without interrupting production.

This capability expands what is possible with Hot-tek Hot Inspection and Hot-tek Tube Stabilization, enabling our teams to reach locations that were previously inaccessible during operation.

Why Create Access Online?

Issues such as shell hot spots or tube issues often appear unexpectedly. Addressing the exact problem can be impossible without direct internal inspection, but shutting down can be costly and disruptive.

Hot-tek solves this by:

- Removing debris and deposits online

- Creating safe, engineered openings during operation

- Allowing insertion of specialised tools and diagnostic equipment

- Installing robust, reusable access ports for future maintenance

This gives operators immediate insight and a permanent reliability advantage.

Integrated with Hot Inspection & Hot Repair Services

Once access is created, IGS can deploy the full suite of Hot-tek services, including:

Hot Inspection

Using the patented Lancescope™, internal inspections are performed at temperatures up to 3000°F (1650°C) while the unit remains fully online.

This allows precise identification of:

- Refractory failures

- Tube distortion or instability

- Localised overheating

- Blockages or debris accumulation

Hot Repair & Stabilisation

Targeted services can then be applied immediately, such as:

This approach eliminates guesswork and avoids unnecessary shutdowns.

Operational Benefits

Integrating Hot Access Creation into your reliability strategy helps you:

- Extend run lengths between turnarounds

- Reduce risk of unplanned outages by diagnosing issues early

- Maintain emissions and thermal efficiency

- Increase maintenance flexibility with permanent access where you need it most

Live, online maintenance transforms how operators manage fired heater integrity and uptime.

Delivered with Safety and Precision

Every Hot-tek access creation activity is performed by certified specialists using engineered procedures, detailed risk assessments, and site-specific permit systems.

Safety and control are fundamental to how we execute high-temperature work.

WATCH VIDEO: How Long Does Hot Convection Cleaning Take?

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.