Eliminate PWHT and Protect Your Alky Reactors in Just Three Critical Path Days

Proven HVTS® Solution for H₂SO₄ Alkylation Corrosion

In sulfuric acid alkylation units (SAAUs), severe corrosion caused by high-concentration H₂SO₄ can lead to costly repairs, extended downtime, and major safety risks. Weld Metal Overlay (WMO) is traditionally used to address this problem — but it comes with long application times, high stress on the asset, and the need for Post Weld Heat Treatment (PWHT).

IGS High Velocity Thermal Spray (HVTS®) offers a superior solution:

- No PWHT required

- Application completed in 3 shifts

- Proven long-term corrosion protection

- Millions saved in avoided downtime

The Challenge: Sulfuric Acid Corrosion in Alky Reactors

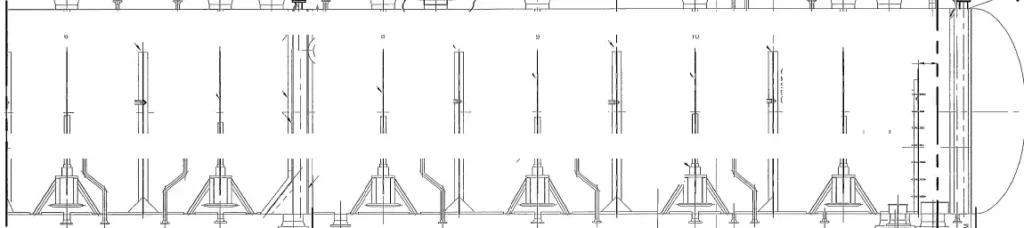

A major Gulf Coast refinery faced internal metal loss in three sulfuric acid alkylation reactors due to sustained exposure to high-strength H₂SO₄. The equipment was on the turnaround’s critical path, and the client needed a fast, proven corrosion barrier that wouldn’t introduce heat-related risks or delay the project.

The goal:

- Avoid full window replacement or WMO

- Apply a protective corrosion-resistant alloy in the shortest possible time

- Eliminate the need for PWHT and preserve structural integrity

The IGS HVTS® Solution

Following rigorous technical evaluation and testing, IGS HVTS® was approved by the refinery’s corporate engineering team for the application.

Why HVTS®?

- No Heat Affected Zone (HAZ) — avoids structural stress

- No preheat or post-weld heat treatment

- Dense, impermeable CRA barrier — stops acid permeation

- True high-velocity spray — superior adhesion, low porosity

Our 5000-series alloy system is engineered to resist H₂SO₄ acid attack and isolate the base material from further chemical interaction. HVTS® cladding effectively halts corrosion mechanisms without the downtime and risks associated with traditional overlay.

The Application: On-Time, On-Spec, On-Budget

Despite the complex geometry of the internal vessels — including fixed baffles and internal hardware — the IGS team completed the entire application within six shifts per unit.

- All work was delivered in just 3 critical path days per reactor

- Zero safety incidents

- Full specification compliance

By comparison, Weld Metal Overlay would have extended the critical path by up to 21 days, significantly impacting the turnaround schedule.

The Value: Millions Saved in Turnaround Costs

Refineries estimate that each critical path day costs approximately $1 million USD. By choosing IGS HVTS®, this client avoided 18 extra days of critical path time — resulting in a cost saving of over $18 million for this project alone.

“The client is delighted with the results. We completed the work within the allocated timeframe, and the units are now protected from further degradation.”

— Eric Duvekot, Director of North American Operations, IGS

This project success has since led to additional IGS HVTS® work across the client’s alkylation network.

Comparison: HVTS® Cladding vs Weld Metal Overlay for Sulfuric Acid Alkylation Units?

Application Time

• HVTS® Cladding: 3 days

• Weld Metal Overlay: 21+ days

PWHT Required

• HVTS® Cladding: No

• Weld Metal Overlay: Yes

HAZ (Heat Affected Zone) Created

• HVTS® Cladding: No

• Weld Metal Overlay: Yes

Thermal Stress

• HVTS® Cladding: Low

• Weld Metal Overlay: High

Critical Path Impact

• HVTS® Cladding: Minimal

• Weld Metal Overlay: Significant

Let’s Talk About Your H₂SO₄ Alkylation Corrosion Challenge

If you’re planning a turnaround or need to mitigate corrosion in your alkylation reactors, speak to IGS today. Our HVTS® solution is field-proven, fast, and built for harsh acid service.

I’m here to help

Colin Bateman

IGS Subject Matter Expert

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.