H₂S Corrosion Control in Oil & Gas Production

Protecting Amine Systems, Slug Catchers & Desalters with HVTS® Cladding

Proven Alloy Cladding Technology to Stop Hydrogen Sulfide Corrosion – No Weld Overlay. No PWHT. No Compromise.

Understanding the Risk: H₂S Corrosion in Oil & Gas Production

Hydrogen sulfide (H₂S) is among the most aggressive and costly corrosive agents found in oil and gas processing environments. From upstream slug catchers to downstream amine regenerators and crude desalters, H₂S corrosion can compromise asset integrity, reduce equipment life, and cause unplanned shutdowns — often without warning.

At IGS, we understand the root causes and failure mechanisms behind H₂S corrosion. With more than two decades of experience applying in-situ High Velocity Thermal Spray (HVTS®) cladding to critical pressure vessels, we provide asset protection strategies that outperform traditional repair techniques and coatings.

Where H₂S Corrosion Strikes

H₂S corrosion mechanisms typically involve localized attack, particularly in areas with:

- High temperature gradients

- Acid gas breakout

- Two-phase flow or flashing conditions

- CO₂–H₂S mixtures, which amplify corrosivity

Key Areas Affected: Amine Systems, Desalters, Slug Catchers

- Amine regenerators and CO₂ strippers – Elevated temperatures in the reboiler and bottom trays lead to rapid pitting, crevice corrosion, and metal loss.

- Crude desalters – H₂S in the water-in-oil emulsion phase contributes to under-deposit corrosion and cracking, especially when chloride hydrolysis forms hydrochloric acid.

- H₂S slug catchers and upstream vessels – Sour service lines face continuous exposure to H₂S, increasing the risk of general corrosion and sulfide stress cracking.

HVTS®: Field-Proven Barrier Against H₂S Corrosion

IGS HVTS® 5xxx Series is a proprietary corrosion-resistant alloy (CRA) cladding system applied on-site to mitigate H₂S corrosion and prevent further metal wastage. Unlike weld overlays or organic coatings, HVTS® offers:

- No Post Weld Heat Treatment (PWHT)

- No Heat-Affected Zone (HAZ)

- No cure time or recoating cycles

- Fast, safe application – even in confined vessels

Our NiCrMo alloy cladding creates a dense, impermeable surface that resists chemical attack from hydrogen sulfide, carbon dioxide, water vapour, and cleaning chemicals.

Case Study: 6+ Years of H₂S Corrosion Resistance in an Amine Regenerator

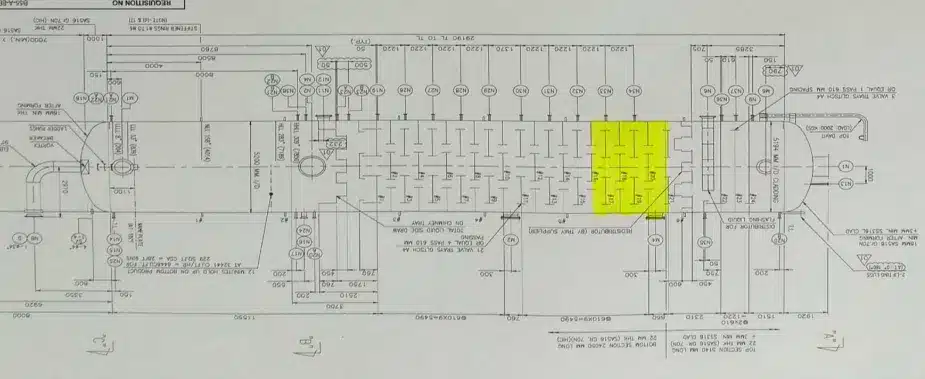

A major gas processing facility in the Rub’ al-Khali desert, Saudi Arabia, experienced severe high-temperature H₂S corrosion in the upper trays of a 2.4 BSCFD Amine Regenerator column.

Rather than resorting to costly weld repairs, IGS installed HVTS® cladding across the affected shell, tray rings, downcomers, nozzles, and internal components — all completed in just 7 shifts and without PWHT. Unlike conventional welding, which would have required removing and replacing the internals, HVTS® allowed full protection with minimal disruption.

Six years later, inspection revealed no degradation, and the HVTS® cladding remains in excellent condition.

Key Outcome: Long-term protection, reduced downtime, zero safety incidents, and full structural integrity preserved.

H₂S Corrosion in Desalters: Why Coatings Fail

Desalters often suffer from severe pitting corrosion in the bottom third of the vessel — the liquid phase. This is where H₂S, residual chlorides, and cleaning agents combine to create highly corrosive localized conditions. Organic coatings, when used, tend to break down under steam-out, thermal cycling, or abrasive cleaning.

IGS has protected dozens of desalters worldwide, with HVTS® cladding performing reliably for over 10 years in continuous operation.

HVTS® cladding offers a permanent solution, with:

-

Robust performance in wet H₂S environments

-

Steam-out resistance

-

Compatibility with standard inspection techniques (no blasting or surface prep needed)

One client reported $75 million in combined savings across multiple desalters by switching from coatings to HVTS®.

H₂S Corrosion Mitigation in Slug Catchers and Sour Gas Units

For upstream operators facing H₂S slug catcher corrosion or corrosion in high-pressure gas vessels, HVTS® provides the metallurgical upgrade needed to protect the base steel — without changing the substrate or incurring the delays of fabrication or weld overlay.

Our teams mobilise globally to apply HVTS® in the most demanding environments, ensuring your assets continue to operate safely, efficiently, and within specification.

Why IGS?

- Proprietary Alloy Chemistry – IGS 5XXX Series alloys are engineered to resist H₂S, CO₂, chloride, and acid gas corrosion, validated through rigorous lab and field testing.

- On-Site Application – No shipping. No hot work risks. HVTS® is applied in-situ, with custom tooling to protect tolerances and maintain vessel geometry.

- Verified Performance – All projects include electronic thickness mapping, visual inspection protocols, and ongoing support. Our claddings are designed to last entire inspection cycles, reducing the frequency and cost of future maintenance.

- Global References – With more than 3000 m² of internal surface protected in amine vessels alone, IGS is the trusted corrosion mitigation partner for top-tier operators worldwide.

Let’s Talk About Your H₂S Corrosion Challenge

Whether you’re planning a turnaround or responding to an urgent corrosion issue, IGS can help you evaluate your options and deliver a fit-for-purpose solution with proven ROI.

I’m here to help

Colin Bateman

IGS Subject Matter Expert

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.