Protecting Critical Weld Zones and Tube Sheet Substrates for Long-Term Furnace Efficiency

Olefins Facility Strengthens Reliability in TLE Application

At a major olefins production facility in Mexico, the Unit 4 cracking furnace plays a pivotal role in ethylene production. With growing operational demands and tight turnaround windows, reliability in the most exposed areas of the process has become non-negotiable.

Targeting the Root Cause, Not Just the Symptoms

Challenge

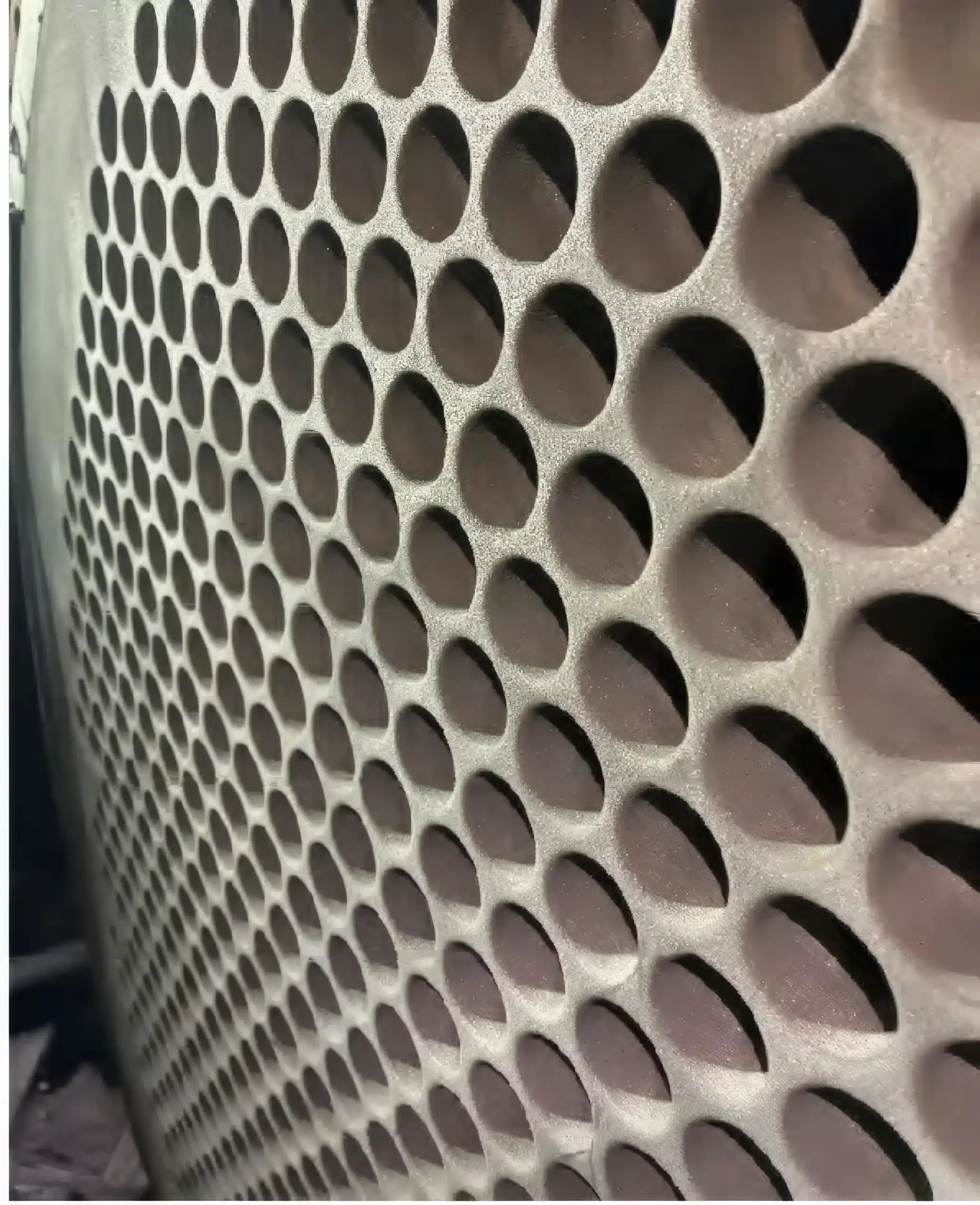

The facility faced severe coking-related erosion at weld seams and tube ID transitions. The most aggressive degradation occurred in the transition zone between TLE faces #2 and #3, where coked process streams changed direction—creating turbulence and an erosion/corrosion mechanism that impacted key weld seams, inlet interiors, and the face of the TLE’s tube sheets.

Particularly problematic areas included:

- Weld seam 1 on the tube sheet face

- Weld seam 2 where tubes join the cupped protrusion zone

- Tube ID entrances, exposed to high-velocity particulate flow

These areas could not be effectively protected with hard-phase metals through traditional welding. The plant’s short-term workaround—welding protective plugs on eroded inlets—introduced pressure drop and failed to address deeper degradation across weld seams and inner IDs.

Smarter Application with Real-Time Scope Adaptation

Why the Facility Chose IGS

IGS was brought in to deliver an advanced, fully documented cladding solution that addressed both known and emerging damage zones in the Transfer Line Exchanger (TLE) system.

Upon blasting and inspecting the unit, the team uncovered additional corrosion inside the tube inlets, prompting an expanded project scope to include these areas – enhancing thermal protection, improving furnace efficiency, and ensuring long-term reliability.

Execution Details

- A modified Inconel superalloy wire was applied, engineered specifically for erosion and corrosion resistance.

- IGS topcoat system applied to ensure maximum barrier integrity.

- Overspray cladding provided opportunistic protection to the entrance zone of the tube IDs.

- HVTS application covered both critical weld seams, the tube sheet face, and the cupped protrusion zone.

- The proprietary system enabled precise application without heat input, distortion, or any impact to base metal integrity.

“Every turnaround has its surprises. But with IGS, we didn’t just react — we got ahead of the problem. Their agility, ownership, and professionalism made all the difference.”

– Maintenance Manager, Olefins Producer

Ready for What’s Next

Outcome and Future Opportunity

The transition zone of Furnace #4’s TLE is now fully clad, including the tube face, cupped protrusion zone, both weld seams, and inner tube IDs—eliminating the need for future plug welds and restoring full process capability.

The validated cladding thicknesses exceeded 500 microns throughout, with inspection reports confirming full adhesion and protective performance.

Following this successful application, the facility’s maintenance team has expressed strong interest in extending IGS cladding solutions to additional units, reinforcing long-term reliability and protection across the operation.

“This was one of those projects where everything had to go right — and it did. Our team adapted quickly to changes in scope, maintained strict quality controls, and finished ahead of schedule. The support on-site was exceptional, and together we delivered a long-term solution for one of their most critical assets.”

– Alejandro Macias, IGS Operations Manager, LATAM

Rapid Delivery with Strategic Impact

IGS completed the project ahead of schedule — in just six days.

This flexibility, combined with strict quality adherence and 24-hour progress reporting, enabled the facility to expedite its turnaround schedule and return Furnace #4 to production early. The result was a significant improvement in protection across one of the most damage-prone zones of the furnace.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.