Methanol Plant Heat Exchanger Stress Corrosion Cracking Stopped

At a leading methanol production facility in the Middle East, internal stress corrosion cracking threatened the reliability of a critical heat exchanger. IGS applied its proven High Velocity Thermal Spray (HVTS) technology to repair chloride-induced damage and protect the equipment from future corrosion.

Problem: Stress Corrosion Cracking

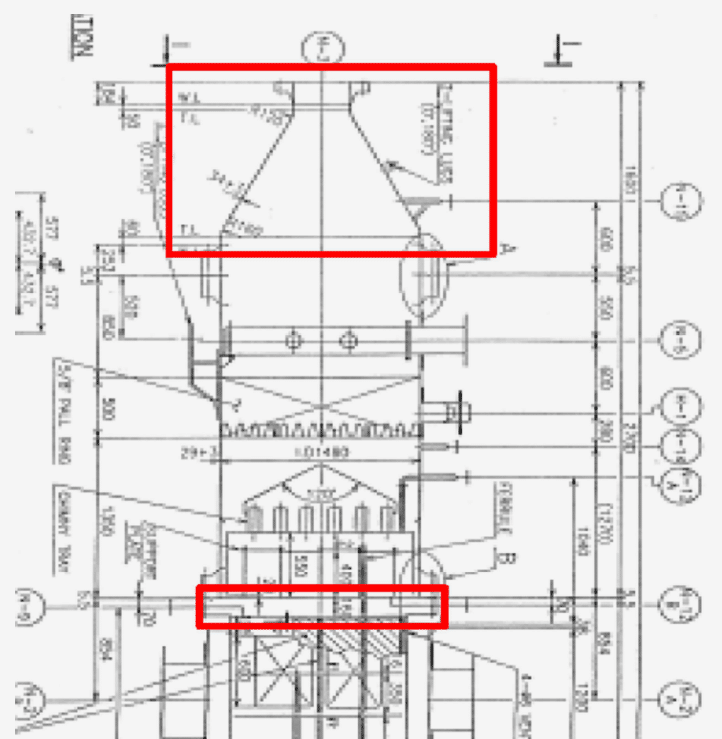

During a planned turnaround, internal surfaces of the heat exchanger in the methanol production unit were found to have micro Stress Corrosion Cracking (SCC) caused by chloride and sulphide attack and general corrosion within the process stream.

The plant maintenance team attempted to grind out some cracks but was unable to reach the affected areas between tubes. There was also concern that grinding might cause the cracks to propagate further, compromising long-term integrity.

Solution: HVTS Cladding to Stop SCC and Extend Equipment Life

The methanol plant needed the heat exchanger back in service within days. IGS rapidly mobilized local resources to deliver an immediate, permanent solution.

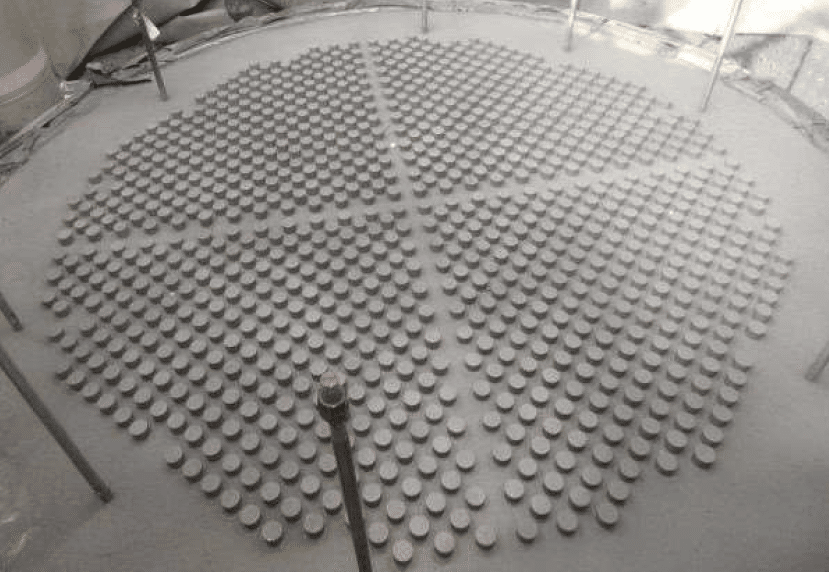

IGS HVTS (High Velocity Thermal Spray) cladding was applied to the tube sheet and cone regions, providing a dense, corrosion-resistant CRA barrier against chloride and sulphide attack. The repair was completed safely and within schedule, allowing the unit to resume operation promptly.

Emergency Maintenance – Our Routine Expertise

The unexpected SCC issue had the potential to delay the entire turnaround. IGS corrosion experts assessed the problem, engineered a fit-for-service alloy solution, and deployed an in-country team to perform the HVTS coating application.

Following extensive surface preparation, the HVTS alloy cladding successfully halted corrosion and prevented further crack propagation. The heat exchanger was returned to service on time, ensuring continuous methanol production with no safety concerns.

Application Steps

The IGS team developed a comprehensive corrosion protection plan.

1. Situation Analysis

The plant maintenance team attempted grinding out some cracks but failed due to the complexity of crack locations (in between tubes) and fear of the cracks propagating further.

2. IGS HVTS Solution

IGS quickly responded to this emergent need. IGS HVTS cladding was applied onto the tube sheet and cone regions of the heat exchanger, facilitating its prompt return to service.

3. Ensuring Lasting Protection

Upon completion of the cladding application, IGS performed coating thickness and quality inspections. A complete thickness report was compiled for all applied cladding, and the final ITP and Quality Control book was signed and shared with the asset owner’s inspection group.

Follow-Up Inspection Success

In January 2025, five years after the initial HVTS application on the tube sheet and cone of the HEX E-4222 NG Saturator in Plant 4, an inspection was conducted to evaluate the long-term performance of the cladding. The HVTS coating was found to be in excellent condition, confirming its durability and long-term protection against stress corrosion cracking and corrosion mechanisms. This inspection result demonstrates the effectiveness of IGS’ HVTS solution in safeguarding critical assets over extended operational periods.

Unexpected Corrosion? Your Emergency is Our Routine.

IGS can be on site 24–48 hours after you discover an issue. Multiple equipment staging areas around the world and a dedicated team on standby enable us to support all major asset owners during turnarounds.

Our solutions do not require pre- or postweld heat treatment and have no cure times, facilitating rapid back-to-service times.

Engineered Alloys

Our High Velocity Alloy Cladding systems are specifically engineered for their intended environments. IGS can replicate your process conditions and test the suggested cladding for your project in our state-of-the-art Technology Centre in Richmond, USA.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.