Hot Tube Stabilization During Crude Heater Operation

Rapid Maintenance Solution at a US Refinery

A refinery in Montana, USA, with a processing capacity of 205,000 barrels of crude oil per day, faced a recurring issue after an earlier emergency shutdown caused by an electrical outage. The outage left multiple tube supports unstable, leading to the need for a proactive hot tube stabilization service. To avoid future risks, the refinery sought a rapid on-line crude heater maintenance solution that wouldn’t interrupt operations.

The Challenge

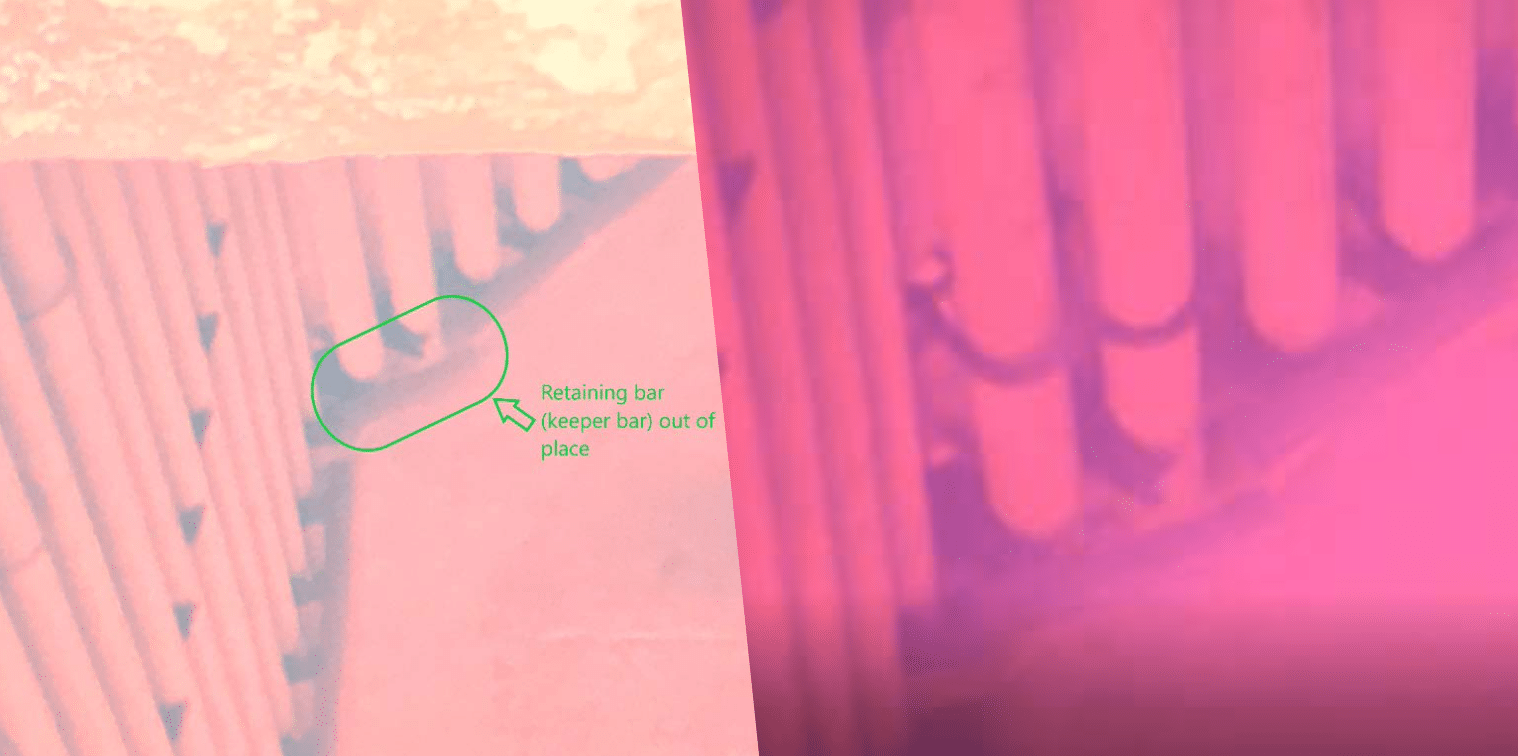

Two tubes in the crude heater had partially lost their support when a retaining bar fell out of place. With the next scheduled turnaround still months away, the risk of an unplanned shutdown was too great to ignore.

Image left: Retaining bar out of place

Image right: Finished application (interior)

The IGS Hot-tek™ Solution

Integrated Global Services (IGS) responded quickly, delivering a turnkey hot tube stabilization service without interrupting refinery operations. The team supplied tube stabilizers made from 310 stainless steel, along with experienced welders and all required consumables.

The job was completed over two shifts using IGS’s proprietary J-Hooks, ensuring tube stability during ongoing operation.

Image: Finished application (exterior)

Highlights

-

Turnkey tube stabilization service

-

No shutdown required

-

Installed during normal heater operation

-

Completed in two shifts

-

310 SS stabilizers + J-Hook technology

I’m here to help

Larry Emch

IGS Subject Matter Expert

Related Case Studies

- Hot Spot Repair on Ammonia Reformer Saves $Millions by Preventing Emergency Shutdown

- Online Scale Removal on Fired Heater Improves Efficiency and Cuts Fuel Consumption

- Hot Spot Repair on a Live Fired Heater

- Primary Ammonia Reformer Excessive Fuel and Emissions

- Refractory Coating Achieves 4% Fuel Savings For An Ammonia Reformer

Ensure Reliable Operation Without Shutdown

Contact IGS to discuss your heater reliability and on-line maintenance needs.