Fast SCR Defouling Restores Flow and Reduces ΔP

Plant and Challenge Description

At a leading methanol production facility on the U.S. Gulf Coast, reliability and output are key. The plant’s operations depend heavily on the efficiency of its Selective Catalytic Reduction (SCR) unit — a vital component in emissions control and overall process performance.

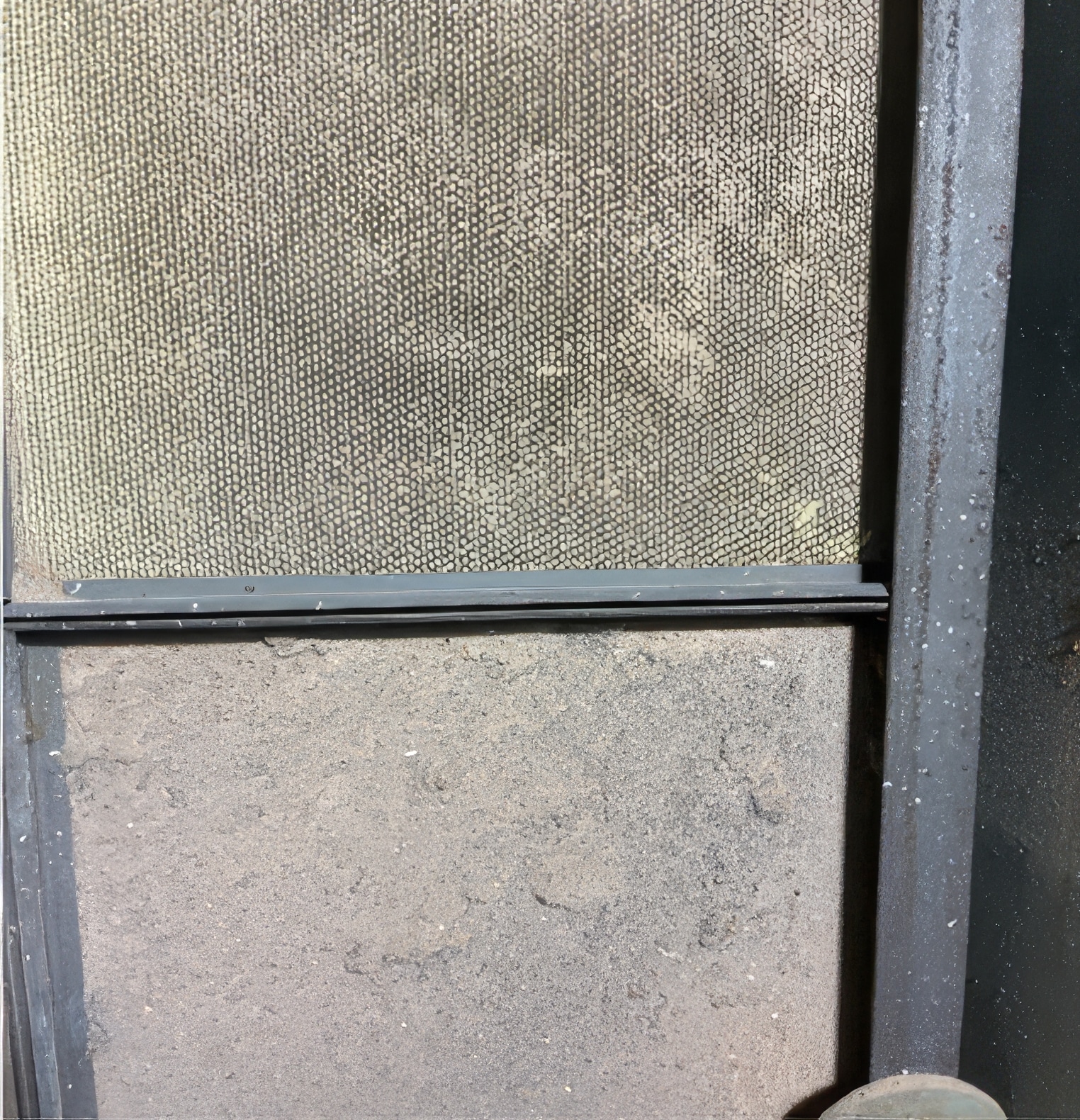

However, significant debris buildup across the SCR catalyst had gradually compromised flow efficiency, leading to an elevated differential pressure (ΔP) of 13″ H₂O. This created unnecessary strain on upstream equipment and reduced consistent throughput.

The objective was to restore SCR performance within a short, scheduled shutdown window, safely and thoroughly, with zero impact on restart timelines.

Evaluating Corrosion Barrier Methods

Given the narrow time frame, plant personnel explored various maintenance paths. Traditional mechanical cleaning methods were considered but posed risks of incomplete debris removal, potential catalyst damage, limited reach, or extended downtime.

The facility ultimately selected IGS for its proven ability to deliver comprehensive, high-precision SCR cleaning services.

While the SCR defouling service is typically performed online to avoid outages altogether, in this instance, the plant utilized a brief, planned shutdown to perform the cleaning offline, maximizing efficiency during the turnaround window.

IGS Solution Delivery

IGS deployed a specialized team to execute an offline rapid SCR defouling service. Using confined-space scaffolding, the crew accessed 100% of the catalyst surface and performed a detailed vacuuming of both the catalyst and floor area. The cleaning was completed within the allocated timeframe, with zero safety incidents and full adherence to IGS and client safety protocols.

Additionally, a low-emissivity ceramic coating was applied in the transition section to encapsulate exposed ceramic fiber insulation. This area experiences the most aggressive flue gas turbulence and erosion, making encapsulation critical for protection and long-term durability.

Quantifiable Impact and Proven Results

The Results

- Differential pressure reduced from 13″ H₂O to 7″ H₂O

- SCR screens cleaned, restoring effective flow paths and improving operational consistency

- Production resumed on schedule, with full SCR performance restored

The plant team commended the IGS crew’s professionalism and skill, noting their proactive approach and strong commitment to safety throughout the project.

Future Recommendations

Beyond the immediate success, IGS highlighted several future mitigation options to further enhance system performance and efficiency. TubeTech™ convection section cleaning to restore heat transfer efficiency, reduce fuel consumption, and boost overall energy recovery.

Evaluation of a ceramic coating application in the radiant section, either before or after the installation of a fine particle screen. The final coating selection will be determined following a detailed assessment of the operating environment and the desired performance outcomes, ensuring long-term reliability and optimized plant efficiency.

Project Comment

“Our objective wasn’t just to clean the SCR – it was to help this plant achieve operational certainty during a time-sensitive shutdown. We take pride in delivering solutions that allow our partners to resume production with confidence and measurable improvements in performance.”

Mike Corcoran, Project Manager, IGS

TubeTech™ Fouling Removal Services

Heat Exchanger Fouling Removal Services:

- Shell and Tube Heat Exchanger Fouling Removal

- Fired Heater Furnace Fouling Removal

- Texas Tower (VCFE) Fouling Removal

- Twisted Tube Heat Exchanger Fouling Removal

- U-Tube (Hairpin) Heat Exchanger Fouling Removal

Air Cooled Condenser Fouling Removal (ACC)

Fouling Removal for Inspection:

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.