SMARTGard®: Weld Overlay Alternative for Boiler Pressure Parts

A waste-to-energy plant in Turin, Italy, was preparing for an outage on one of their lines. They were waiting for approval from the notified body to carry out the weld overlay. The outage was nearing, and the approval was yet to come. They had an alternative solution they were considering, which wouldn’t require approval.

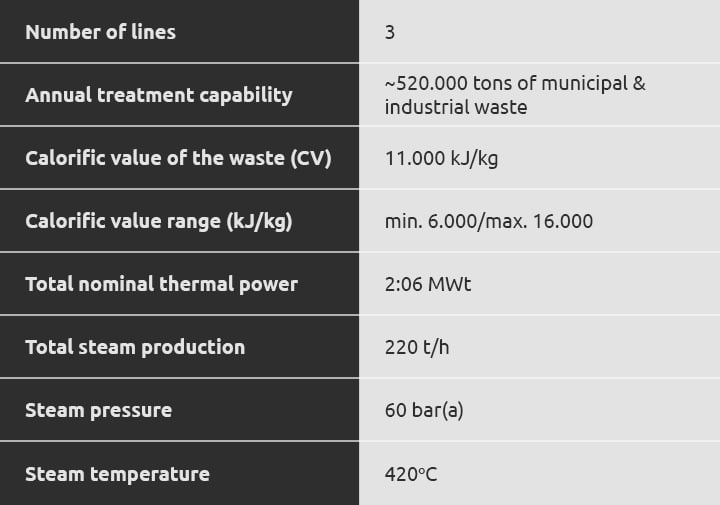

Power Plant

Corrosion of the Boiler Pressure Parts

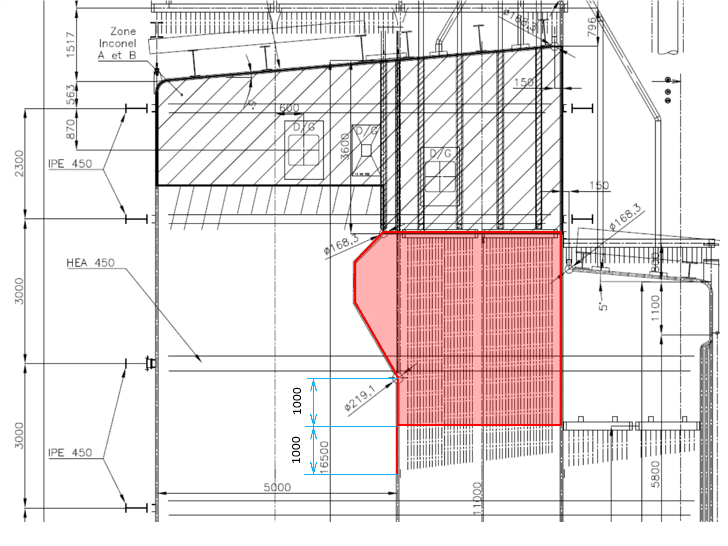

The plant, built by CNIM, was commissioned in 2014. Following several years in operation, they noticed corrosion in the second pass of the boiler. Alloy 625 weld overlay has already been installed in the top of the first and second pass, with refractory covering the area from the grate to the collector at the top of the 1st/2nd pass division wall. After the collector in the second pass, the waterwall had no protection.

Selecting a Suitable Solution

IGS SMARTGard® HVTS was selected for several reasons.

Strong global references in similar applications supported by laboratory testing.

HVTS is not a welding process – the pressure part temperature stays below 150C during the application, therefore, unlike weld overlay, it does not require a NoBo approval.

The outage could proceed as planned with no delays.

HVTS Application in 2019

IGS Europe applied HVTS alloy cladding onto a 159 square meter area below the existing Inconel to cover four walls including the division wall. Cyril Narjoz, IGS Boiler Maintenance Subject Matter Expert, said: “The project was well executed with a good synchronization with the client.”

Inspection in 2020 and Unexpected Scope

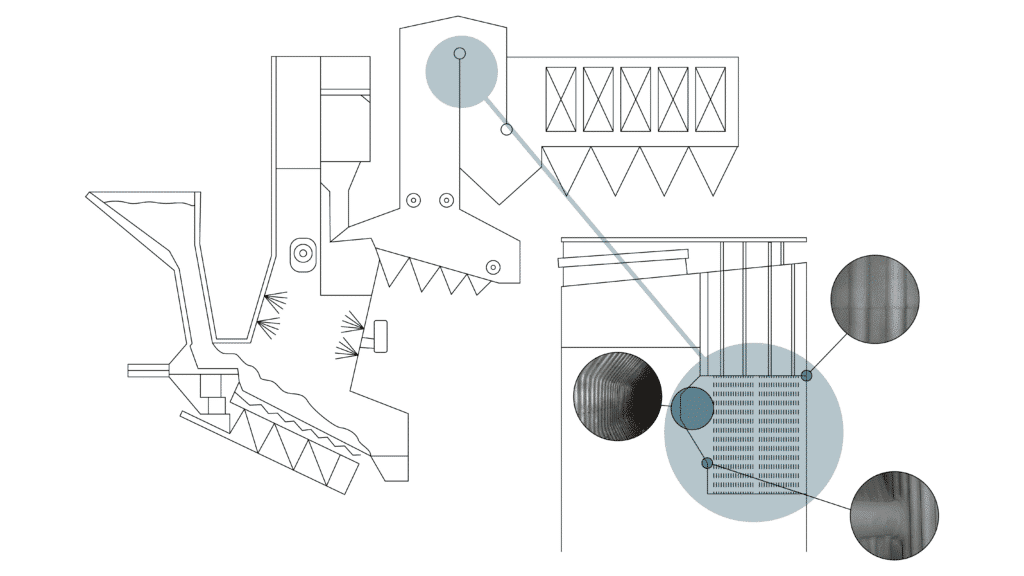

“One year later, in September 2020, we came back to perform an inspection. The IGS HVTS cladding was in good shape, but the client was worried about the pendant screens in the same area, not protected with HVTS and already replaced”, said Cyril.

In the second pass, this boiler has hanging evaporator panels that increase the surface exchange for the temperature transfer. The plant has already replaced them a few years before, and now noticed some signs of degradation, which were confirmed with UT readings performed by IGS. The plant then asked IGS to urgently protect these hanging panels as an unexpected scope. “Fortunately, we were performing another job nearby, and were able to mobilize very quickly”, added Cyril.

The new scope was executed without any problems. Additional HVTS cladding was applied onto tubes coming from the roof that supply the collector.

Inspection in 2021

Throughout 2020 the plant performed no repairs and had no tube leaks. At the end of 2021, another inspection of the area was performed during the application of the 50 square meter scope extension on the division wall. Minor cladded areas were touched up with no concerns for the pressure part integrity.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.