Case Studies

The Global Source for Reliable Surface Protection

Our case studies showcase how our proprietary technologies and expert applications have helped leading companies all around the world overcome critical challenges in corrosion, erosion, and fouling. From petrochemical facilities to power generation plants, these real-world examples demonstrate our commitment to excellence, highlighting significant cost savings, reduced maintenance requirements, and improved asset reliability.

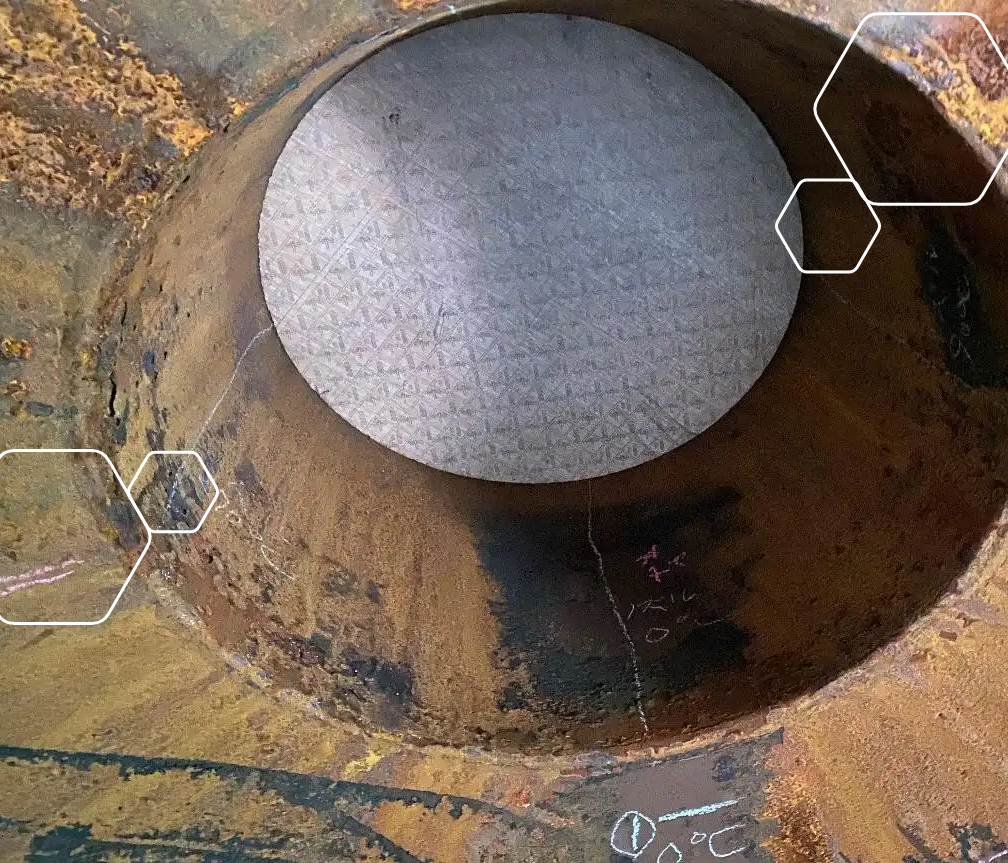

Sulfolane Corrosion Prevention with On-site Alloy Upgrade During Turnaround

A sulfolane unit is a process that uses sulfolane as a solvent to separate aromatics from non-aromatics in a hydrocarbon mixture. Sulfolane is a cyclic sulfone that has high solubility and selectivity for aromatics. A sulfolane unit typically consists of an extraction column, a stripper column, a solvent recovery column, and a solvent regenerator.

Ready full story

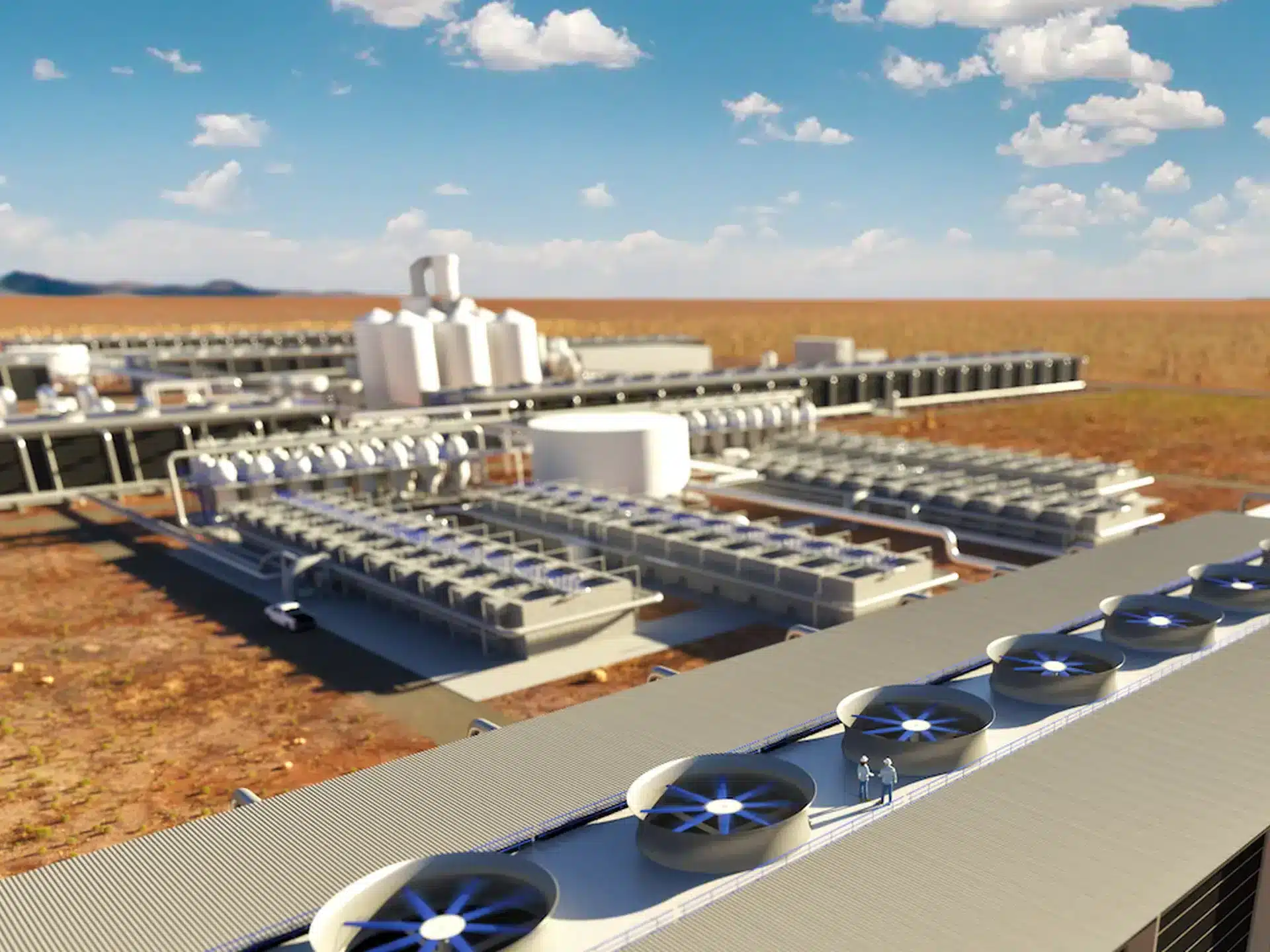

Pioneering Carbon Capture and Storage Project Back on Track with Rapid Mobilization

A multinational investment company and a US energy firm have embarked on constructing a ground-breaking direct air capture facility. The primary objective is to capture atmospheric carbon to sell to major corporations like Amazon, Google, and United Airlines. Urgency was created by the plan to build 100 such facilities in the next decade.

Read full story

A Successful Revamp of a 40-year-old Steam-Methane Reformer Furnace

This case study examines a successful application of Cetek high emissivity coating to the radiant section of an SMR reformer which was experiencing excessive fuel firing.

Read full story

Filter by