Tüpraş Izmir Refinery in Turkey Increases Efficiency by 3%

The refinery had been experiencing reduced performance due to fouling on convection bank tubes within a steam methane reformer. Due to the inaccessible location of the tubes, the unit had not been cleaned since it came online in 1993. IGS was chosen to apply Cetek’s High Emissivity Coating followed by TubeTech™’s convection section cleaning service to achieve several operational benefits.а

The Challenge

The plant experienced reduced heat transfer, higher fuel consumption and an increase in flue gas temperature within its steam methane reformer. The problems arose from the adsorbents in a Pressure Swing Absorption Unit, part of the refinery’s Hydrogen Manufacturing Unit (HMU), being changed during a turnaround.

Once started up, some of these adsorbents were transported by the tail gas stream and facilitated by misplaced screens in one of the beds; the result was an accumulation of fouling on the convection bank tubes of the steam methane reformer.

The Solution: Part 1

Increasing SMR Radiant Heat Transfer Efficiency

In the SMR, the burners are directed to the angled walls in the radiant sections and the radiation is transferred to the process tubes. The efficiency of the radiant heat transfer is related to the emissivity of the refractory surfaces. The higher the emissivity value, the greater the radiant heat transfer efficiency.

The application of a Cetek high-emissivity coating onto the refractory surface in 2014 increased the amount of heat re-radiated to the process tubes in the radiant section. As a result, more heat is absorbed by the tubes, and less heat travels to the convection section, slightly decreasing steam production.

Post Coating Evaluation

Tüpras report that the bridgewall temperature has decreased by 26°C, a positive indication that the high emissivity ceramic coating is performing well. The amount of heat transferred to the radiant section has increased by 2.9% leading to the reported decrease in energy consumption of 6.8% (released) and 8.3% (absorbed).

Economic Returns

The application of Cetek high-emissivity refractory coating has helped the refinery achieve targeted fuel savings, pay-out and return on investment. The coating continues to deliver benefits for approximately two turnarounds or eight years. After this period, it may require reapplication to continue delivering fuel savings or increased capacity benefits.

The Solution: Part 2

Restoring Convection Section Heat Transfer Efficiency

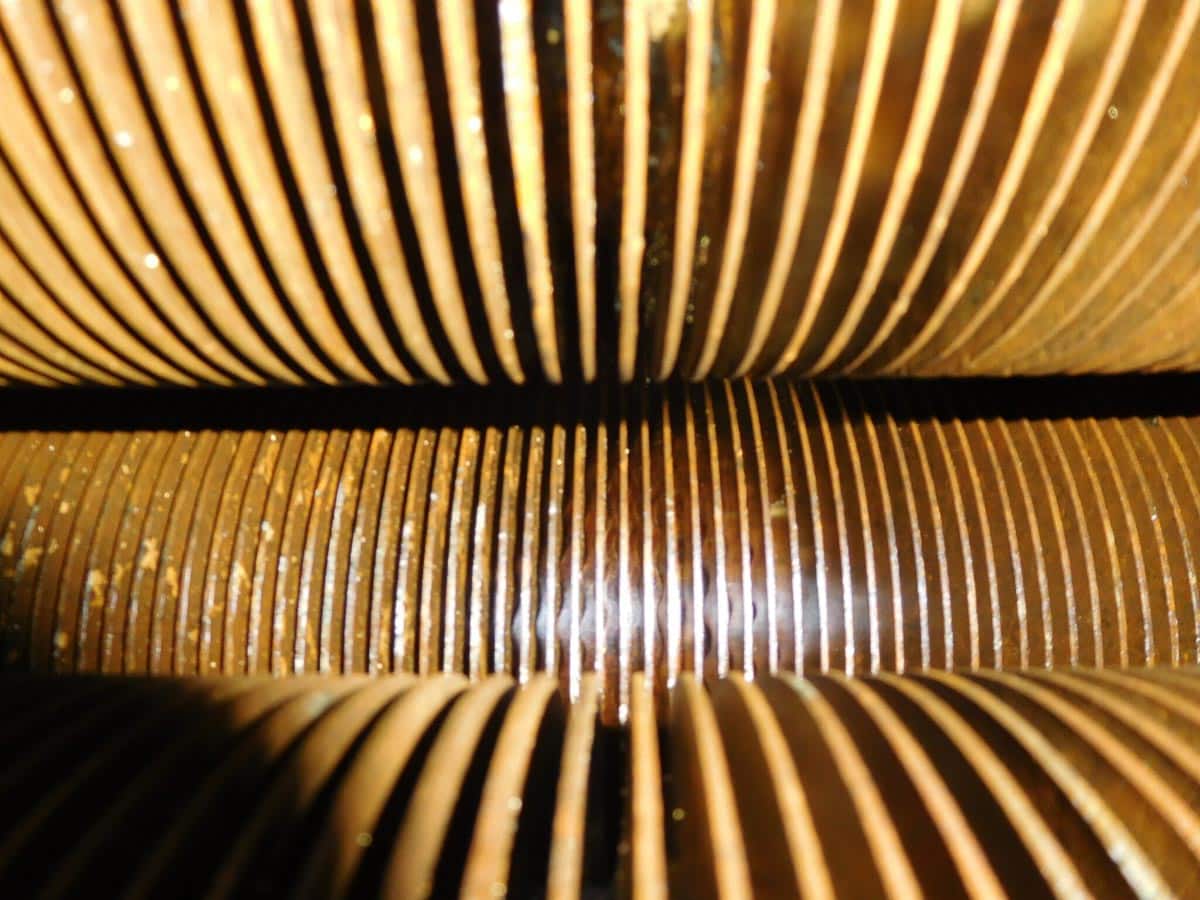

To increase heat transfer and therefore absorb more energy in the convection section of the furnace, the decision was taken to carry out mechanical cleaning. In addition, and as further motivation for the project, since the first start-up of the unit, no mechanical cleaning had been carried out in the convection tubes due to their inaccessible locations.

In 2017, Tüpras contacted TubeTech™ to deploy its robotic convection section fouling removal robot. The technology works remotely by penetrating deep between tube rows to remove even the most tenacious fouling deposits.

Results

Hydrogen Production Cost and ROI

The average cost of hydrogen production before and after the project was calculated at $943.9-919.3 $/t. The production cost of hydrogen decreased by $24.6/t and the payback period for the project was less than 60 days.

Flue Gas Temperature

The average flue gas temperature decreased from 278°C to 220°C. This translates to a 3% increase in the furnace’s thermal efficiency.

Steam Production

Steam production increased by approximately 20%, and the generated steam temperature increased by 10°C-15°C.

IGS Comment

“This was a great project to be a part of; we often come across convection banks that have never been cleaned before, simply because they are deemed inaccessible or too difficult to restore to design efficiency.

“Our portfolio of fired heater services ensured that fouling was removed precisely and efficiently, whilst improving radiant heat transfer. Due to this bespoke approach, we are proud to be able to guarantee heat transfer restoration for our clients. We look forward to working with the refinery on future projects.”

The IGS Surface Solutions Package

Cetek high emissivity coatings and TubeTech™ robotic convection section cleaning are great ways to increase the efficiency of a fired heater. Applied together, they help to leverage the overall benefits. IGS has extensive experience in turn-key project execution in all parts of the world.

Is your facility suffering from reduced output? Contact our team today for expert advice and tailored solutions across a range of industries and applications.

Watch: How IGS’ Solutions Increase Refinery Efficiency and Reduce Co2 Emissions

Is your facility suffering from reduced output?

Talk to an IGS Subject Matter Expert today