IGS Furnace Hot Spot Repair in the Live Tail Gas Incinerator Saves $156 Million

Hot spots in the Shell of the Sulfur Recovery Unit Tail Gas Incinerator

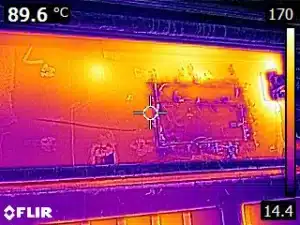

In September, an oil and gas producer in Central Asia faced a critical issue with their Sulfur Recovery Unit, Tail Gas Incinerator, as hot spots emerged in the shell due to a failed refractory lining leading to thermal ruptures. The potential consequences were severe, with the risk of a shutdown looming. IGS was invited to perform Hot Refractory Repair (HRR), preventing a costly shutdown and addressing the immediate concerns.

The Challenge of the Industrial Furnace Hot Refractory Repair service

The Tail Gas Incinerator is part of a single-train plant which accounts for approximately half of the entire field’s production. The field’s total production for the first 9 months was 634,065 barrels per day, with 317,032 from the single-train plant, 211,354 barrels per day going through the sulfur train. This incinerator plays a crucial role in the plant’s sulfur recovery operations.

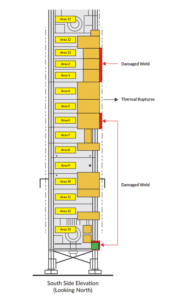

The incinerator had 13 critical hot spots and thermal breakthroughs, leading to thermal ruptures in multiple areas. With a planned turnaround not scheduled for another 3 years, they were confronted with the urgent need for repairs. The hot spots were widely distributed across the furnace shell, making steam-quenching impossible as a temporary treatment. Due to the plant being a single train, there were no options to bypass or divert to other trains with ullage. The lack of alternative solutions and the severity of the situation left them with no option but to address the issue on live equipment.

Tail Gas Incinerator and its schematic showing 13 hotspot areas

Risk and Safety Considerations

Working on a live sulfur incinerator posed higher risks due to the burning of hazardous gases. The IGS Hot-tek Online Services team used specialized personal protective equipment (PPE), including thermal suits and full-face masks with self-contained breathing apparatus (SCBA), to ensure safety during the repair process. The execution team maintained constant communication with the Operators to identify any potential upcoming safety risks.

Project Execution: IGS Hot Spot Repair

The repair project involved addressing 13 known hot spots in the Tail Gas Incinerator. The method statement outlined procedures followed during the repair, emphasizing safety measures and the timeline for completing the repairs.

It was essential to confirm that all necessary gas tests have been conducted, and the unit was operating under negative pressure. A fire watch was present before and after any hot work. The scaffold was inspected, ensuring that the repair areas were within arm’s reach. Fire blankets and Insulated Blankets were installed to protect personnel and cover hot areas. A 20″ x 2″ slot was marked on the furnace wall shell and cut using a plasma cutter, with precautions taken to prevent metal pieces from entering the furnace. Special attention was given to avoiding any impact on boiler tubes and the mud drum.

Following Hot Access Creation (HAC), proprietary Hot-tek baskets and anchors were inserted into the openings and welded in place. Missing refractory was replaced with pumpable refractory, with the Infrared (IR) camera used to verify external temperatures. The steel shell was then replaced and welded in place.

Commercial Impact of Hot Spot Repair on Sulfur Recovery Unit Refractory Lining

Conservative estimate of daily loss if the sulfur recovery train was shut down is $11,201,762 per day. As a result, the oil and gas producer faced a potential shutdown cost of approximately $156 million in lost revenue. IGS successfully completed the hot refractory repair at a centesimal fraction of the cost. The testimonial from the maintenance manager expressed appreciation for IGS’s work, emphasizing safety, excellence, and cost-effectiveness. This not only averted a significant financial loss but also ensured the continued operation of the Tail Gas Incinerator. He said:

“Appreciate the great work IGS is doing for us. They wrapped everything up safely and with excellence.”

Conclusion of another successful Hot Refractory Repair procedure by IGS

The IGS hot refractory repair project at the plant’s Tail Gas Incinerator showcased the company’s ability to address critical issues promptly and efficiently. The successful execution of the project not only prevented a costly shutdown but also demonstrated IGS’s commitment to safety and engineering excellence. The collaboration between the plant and IGS exemplifies the importance of proactive maintenance in the energy industry, ensuring the uninterrupted production of vital facilities that deliver the energy that the world needs.

Related Case Studies:

- Hot Spot Repair on Ammonia Reformer Saves $Millions by Preventing Emergency Shutdown

- Overcoming Severe Refractory Failure in a Saudi Arabian Refinery

- Shutdown Prevented! Furnace Hot Spot Repair Saves $15 Million

- Live Heater Maintenance Saves Methanol Complex $30 Million

- Ammonia Reformer Hot Spot Repair During Operation

- Fired Heater Shutdown Prevented with Hot Refractory Repair

- Hot Refractory Repair Stops Daily Losses

Hot-tek™ Online Services from IGS:

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.