Mitigating Erosion-Corrosion in Sludge Paddle Dryers

Sludge Paddle Dryers HVOF Cladding Repair

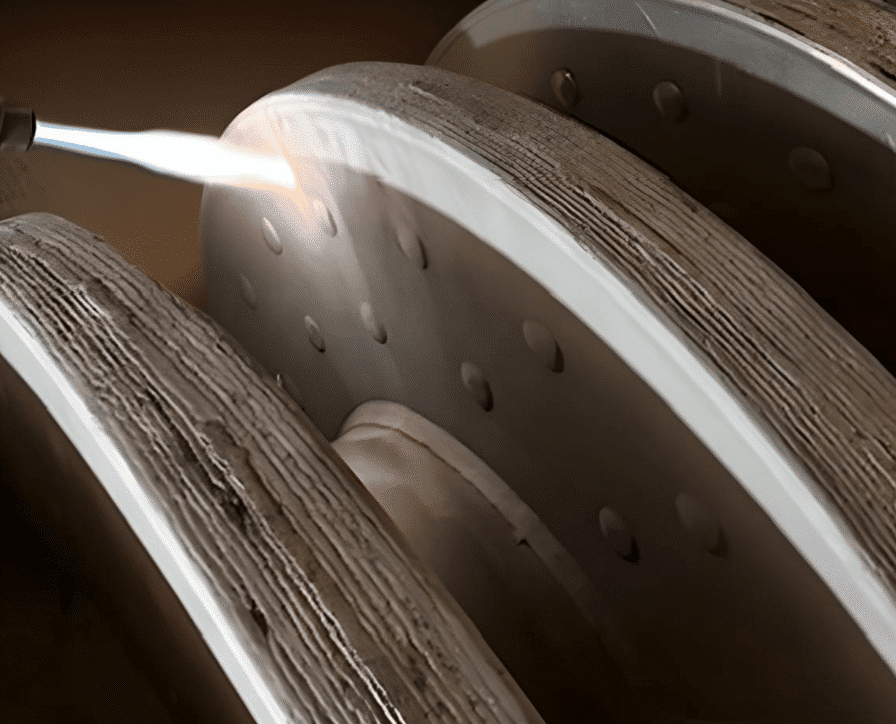

Paddle dryers, also known as paddle processors or dryer-coolers, are used for drying, heating, and cooling materials in industries like biosolids, chemical processing, pharmaceuticals, and food production. The rotating paddle shafts agitate and dry materials but are vulnerable to erosion-corrosion wear over time. Paddle dryers are often manufactured with thermal spray cladding applied as a life extension measure. High Velocity Oxy Fuel (HVOF) thermal spray cladding with the right technology and material will significantly increase the equipment’s lifetime. Thermal spray coating failure can lead to costly repairs, downtime, and compromised product quality. IGS delivers rapid, global solutions for applying or repairing thermal spray on-site with minimal disruption.

Thermal Spray Cladding Longevity

Thermal spray cladding is a proven method to protect paddle dryer components from erosion and corrosion. Applying a thin wear-resistant HVOF cladding during paddle shaft manufacturing drastically extends the equipment’s lifespan. Unfortunately, thermal spray cladding cannot last forever, and in several years, it may need to be repaired.

Sending the paddle shaft to a shop is not feasible. Depending on the circumstances, we can apply the protective cladding with the shafts in place or with the shafts removed and enclosed in a temporary enclosure built in the facility.

Paddle Dryer Repair

IGS specializes in on-site thermal spray cladding for paddle dryers. In recent years, we have had successful cladding applications to agitator shafts both inside and outside the dryer. Welding is often required to restore mechanical paddle thickness, and IGS’s HVOF cladding can be applied directly over that for the erosion component needed in the environment.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.