Ethylene Cracking Furnace Hot Spot Repair Online

Steam Cracker Hot Spot

This case study describes a major Ethylene Plant on the US Gulf Coast where a steam cracking furnace had developed a hot spot on the shell of the radiant section of the furnace. Ethylene cracking furnaces produce ethylene, a crucial component in the chemical industry. The severity of the issue necessitated a prompt and effective resolution to prevent further complications of falling debris/refractory in the furnace and around burners along with general concerns of non-insulating surfaces reducing reliability in those areas.

Ethylene Cracking Furnace

The Steam cracking furnace, operates the radiant section at the temperatures of up to 2150°F (1176°C). The flue gas temperature in this area is high, and the furnace operates under a slightly negative pressure where IGS Hottek services can be provided without having to reduce firing rate or alter normal operating radiant temperatures.

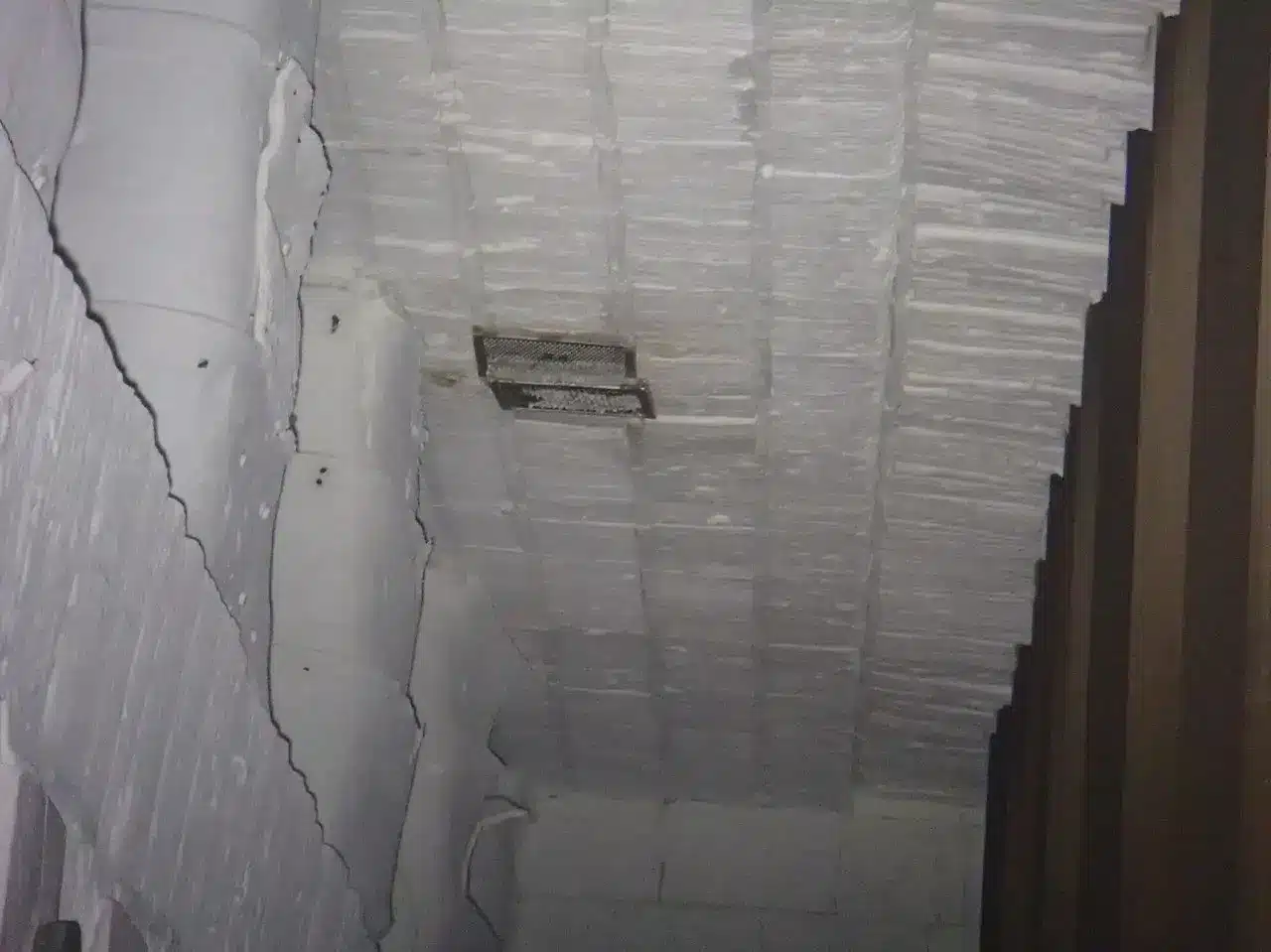

Refractory Failure in the Pyrolysis Furnace

The initial concern was attributed to a Z block refractory issue, stemming from improper installation. A 12-inch by 12-inch refractory block fell from the roof to the flor of the radiant section. This resulted in a hot spot on the cracker shell of the furnace and the carburization of the steel. The internal issue could cause a cascading effect with additional reliability and efficiency concerns, of refractory components continuing to fall into the radiant section of the furnace.

Root Cause Analysis

The root cause of the concern was traced back to the improper installation of the Z block refractory. This issue compromised the attachments that held the components together. The subsequent falling of refractory components into critical areas posed not only a process condition but also potential fire. The plant’s next scheduled turnaround was years away and it did not want to lose production due to an emergency shutdown.

Online Hot Spot Repair

The plant’s engineering team invited Integrated Global Services (IGS) to repair the hot spot during the furnace’s normal operation. IGS has developed a proprietary Hot-tek solution for online hot spot repair. The IGS team creates minimal openings to insert specially designed components and repair material, delivering a semi-permanent repair lasting at least until the next planned turnaround.

Future Considerations

The long-term implications of the hot were not only the resolution of the immediate issue but also the prevention of hot spots on adjacent refractory. The post-job report included comprehensive documentation, including pictures and online inspections, ensuring transparency, and providing valuable insights for future maintenance.

Conclusion

In the dynamic landscape of energy and manufacturing business, timely and precise interventions are crucial to maintaining the reliability and efficiency of critical components. This case study highlights the intricate nature of repairing internal refractory concerns which cause hot spots and the resulting issues for an ethylene furnace, showcasing the expertise and efficiency of the engineering team in resolving complex challenges online, without the need to stop the process.

Hot-tek Services from IGS:

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.