Catalytic Reformer Units (CRU)

Improving Radiant and Convection Section Efficiency

IGS Catalytic Reformer Unit Solutions deliver:

- Maximum operation efficiency

- Increased capacity

- Reduced fuel consumption by up to 15%

- Lower emissions: NOx by up to 25% & CO2 by up to 15%

- Prevention of unplanned shutdowns

Our Solutions

- Radiant Efficiency Increase with Cetek Efficiency Coatings

- Convection Section Efficiency with TubeTech™ Cleaning Services

- Online Maintenance during normal operation with Hot-tek™ Services

Addressing Oxidation and Carburization Issues on the External Surfaces of Fired Heater Radiant Tubes

High-Emissivity Ceramic Coatings for Process Tubes and Refractory

Cetek Ceramic Coatings provide a durable, protective, thin-film layer on the outer surfaces of process tubes, which prevents oxidation, corrosion, and carburization of the metal and maintains the tube thermal conductivity coefficient close to new tube conditions. Tube coating can be applied in conjunction with a high emissivity coating on the refractory surfaces, increasing the benefit and encapsulating the refractory.

Corrosion and carburization result in metal loss and reduced service life.

The Problem

Radiant Tube Oxidation

Radiant tubes in Catalytic Reformer applications in oil refineries are typically steel alloy, ASTM A335 P22, P5, or P9 which contain 2.25%, 5% and 9% Cr respectively. Radiant tubes oxidize at operating temperatures and scale will grow continuously on the surface, often reaching 2mm in thickness in higher temperature / high heat flux units.

The layers of oxide scale are highly insulating and represent a significant barrier to conductive heat transfer to the process fluids. During fired heater operation, to overcome the insulating effects of the oxide and scale layers, it is necessary to increase the firing rate, to maintain the heat flux through to the process feed inside the tubes.

Tube scale results in:

- Increased costs associated with increased firing rate

- increased bridgewall temperature and higher stack temperature

- Increased rate of oxidation

- Tube wall thinning

- Unplanned shutdowns

The Solution

Cetek’s High Emissivity Ceramic Coating system applied to the process tubes ensures maximum conductive heat transfer for the process.

Layers of fouling and scale prevent accurate determination of tube metal temperature, reducing the reliability of those measurements. Cetek applies a thin film layer of ceramic coating which provides a consistent temperature differential between the outside surface and the metal tube. This additionally results in a significant improvement in the reliability of tube metal temperature determination.

The Benefits

- Typical productivity benefits of 4% to 10%

- Fuel Savings

- Production Increases

- Decreased BWT

- Increased Tube Life / Reliability

- Rapid payback on investment

Available Applications:

- In-situ

- Tubes already installed in heaters

- New tubes

Read: ‘Improving Radiant Efficiency in Catalytic Reformers’ Case Study

TubeTech™

Engineered Convection Section Cleaning

TubeTech™’s Catalytic Reformer convection section cleaning service is recognised by world-leading refining and petrochemical companies as the most effective technology to achieve OEM performance clean fired heaters.

90+% clean guarantee even on the most fouled assets

The Problem

Fouling

Catalytic Reformer fouling is a costly problem for refineries around the world. Heater intake collects 1 ppm airborne particulate while in service, which results in deposits of 2.5 tonnes over 12 months either landing in or traveling through the heater.

These deposits most commonly land:

- In the base of Radiant Section

- On Convection Tubes

- In the Air Pre-Heater

Fouling results in:

- More Fuel Consumed

- Increased Emissions

- Higher Stack Temperature

- Heat Stress on Tubes, uneven expansion, and heat distribution

- More Running Costs

- Potential Tube Failure

The Solution

TubeTech™’s Catalytic Reformer convection section cleaning service is recognized by world-leading refining and petrochemical companies as the most effective technology to achieve OEM performance clean Catalytic Reformers.

Traditional cleaning methods are only able to clean 30-45% of the total fouled area. TubeTech™, backed by multi-million-dollar European funding, has developed a Rover system that penetrates deep between tube rows to remove even the most stubborn fouling.

The Benefits

- Removes 95%+ of Fouling

- No Refractory Damage

- Safety – No Man Entry

- Reinstates Thermal Efficiency and Reduces CO2 Emissions

- Extends Asset Life due to Reduced Stack Temperature

Read: ‘TubeTech™ Restores Convection Section at Petrochemical Plant in Bangkok’

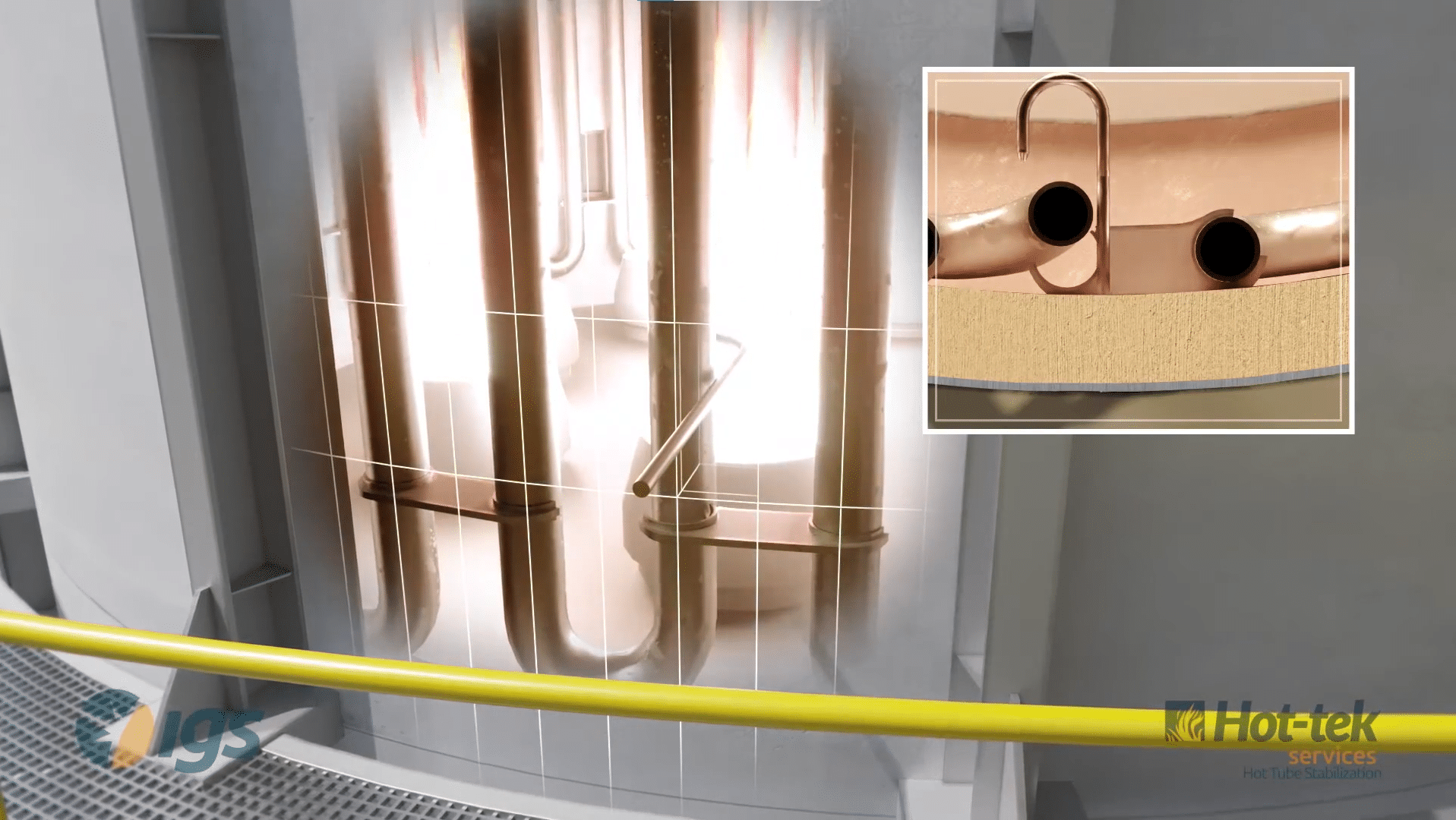

Hot-tek™ Services for Catalytic Reformers

Online Maintenance & Emergency Services (During the Heater’s Normal Operation)

Hot-tek™ is the industry leader in online maintenance, repair, and cleaning of fired heaters during operation, while the unit continues to produce product. IGS holds multiple patents on the approach, methods, and tools used to carry out these services. The approach is customized for every client’s needs. Often, multiple Hot-tek™ Services are employed simultaneously during an application to achieve the best results.

Hot Refractory Repair

The Problem

Failure of refractory material can lead to energy wastage, poor performance and structural damage leading to the eventual need to shut down your Catalytic Reformer.

The Solution

Hot Refractory Repair Services may be made gaining access through the heater steel shell directly behind the damaged area. Minimal openings are used to insert specially designed components to support the repair material. This technique offers a semi-permanent repair method lasting at least until the next planned turnaround.

The Benefits

- Restore Production Rates

- Fast, Effective Short-term Solution

- Avoid Costly Unplanned Shutdowns

Hot Tube Descaling

The Problem

An increase in Bridgewall temperature can be a symptom of excessive fouling of the fired heater’s radiant tubes. These tubes tend to oxidize, and scale will grow under operating conditions. Layers of scale can grow with time to a degree that its insulate the external surfaces of the tubes from the radiant heat. This becomes a significant limiting factor to production capacity. It is even more problematic if there are several years until the next scheduled shutdown.

The Solution

Our patented Hot Tube Descaling service removes radiant section process tube scale, and fouling during furnace operation. The process uses unique water-cooled lances and cleans the tubes while the heater continues to function normally. The process utilizes consumable abrasive media resulting in no increase in emissions.

In some applications, we use Cetek’s LancescopeTM system to view hard to reach areas. We also have the capability to safely create engineered access ports. These ports can be used to facilitate the hot tube descaling process.

The Benefits

- Average bridgewall temperature reduction of 50°F (28°C) to 100°F (56°C).

- Fast, Effective Short-term Solution

- Restore Production Rates

Hot Convection Cleaning

The Problem

Low steam production, low process pre-heat, and high stack temperatures are some of the symptoms of fouled tubes within a convection section.

Fouling results in:

- More Fuel Consumed

- Increased Emissions

- Higher Stack Temperature

- Heat Stress on Tubes, uneven expansion, and heat distribution

- More Running Costs

- Potential Tube Failure

The Solution

Hot Convection Cleaning process removes convection section tube fouling & scale during furnace operation. The tube cleaning process uses consumable abrasive media projected through specially designed application lances to blast away years of accumulation, while the heater is in service.

This emergency or intermediary solution prevents losses associated with taking the heater offline. However, we advise a Planned Preventative Maintenance (PPM) approach, and our TubeTech™ service provides industry-leading offline cleaning services to prevent emergency cleaning situations.

The Benefits

- Increased heat transfer efficiency in the convection section

- Increased steam production

- Increased process pre-heat

- Lower stack temperatures

Hot Inspection Service

The Problem

Sometimes, an issue can arise in high temperature fixed equipment, but you can’t see the cause or the exact location of the problem. We designed and developed Cetek’s Lancescope™ fired heater inspection tool for just this situation. It allows a high-temperature furnace inspection to be carried out to determine the scope of the problem, often avoiding an expensive shut down of the heater.

The Solution

Cetek’s Lancescope™ system provides real-time, close-up, or wide-angle views of virtually any area inside a fired heater, or other high-temperature equipment while it is still in operation.

The hot inspection system uses a state-of-the-art digital camera system, which provides clear, detailed images of problem areas up to 3000°F (1650°C). The furnace inspection system can be inserted into openings as small as 2.75” (7cm) and reach up to 30ft (10m). In applications below 1000°F (540°C), the heater inspection system provides illumination via a high-temperature light source for optimum clarity.

Thorough inspection provides information needed for other Hot-tek online services.

The Benefits

- Performed while unit is in operation

- Provides insight for production availability

- Identifies damage in early stages

- Reduces maintenance costs

- Minimizes repair down time

- Maximizes production

Watch: How do Catalytic Reforming Units (CRU) Maximise Efficiency + Reduce Fuel & Emissions?

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.