Corrosion and Erosion Protection at Refineries for a Leading Oil Company in Japan

Introduction – A Refinery Corrosion Maintenance Strategy

Effective corrosion and erosion protection is crucial for maintaining operational efficiency, worker safety, and asset longevity in the demanding refining process environment, where harsh operating conditions and aggressive media are commonplace. This case study explores how one of Japan’s leading refinery operators, implemented a reliable and long-lasting corrosion maintenance strategy over the last decade.

Background – Corrosion and Erosion Challenges in Mission-Critical Refinery Equipment

A prominent player in the Japanese market, this energy company operates several refineries across the country, including Miyagi, Ibaraki, Chiba, Kanagawa, Okayama, Yamaguchi, and Oita. These facilities experience various corrosion and erosion challenges in their mission-critical refinery equipment, ranging from pitting and material degradation to severe erosion in critical process units including toppers, heat exchangers, CAT coolers, sulfolane and other equipment.

The Challenge – Coating Failures

One of the refineries had experienced recurring issues with coatings applied by service providers. These coatings often failed to provide adequate protection, leading to premature deterioration and costly repairs or replacements during turnarounds. The plant recognized the need for a more reliable and durable solution to extend the service life of their assets and optimize operational efficiency in consideration of 8-year intervals of major shut-down cycles.

The Solution: IGS Japan’s HVTS Cladding

IGS Japan introduced its proprietary High Velocity Thermal Spray cladding (HVTS) to the Okayama plant in 2012, offering a superior alternative to typical coatings. This advanced IGS cladding is applied using a high-velocity thermal spray process, resulting in a dense, metallurgically bonded layer with exceptional resistance to corrosion, erosion, and wear.

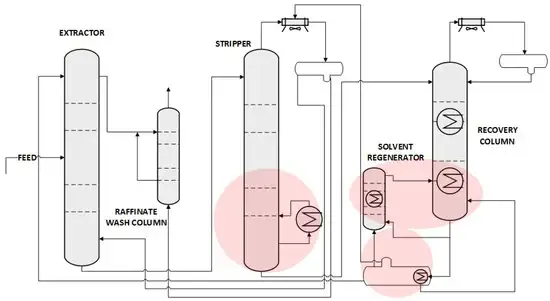

For example, previously, the coating within the refinery’s heavy fuel oil boiler, as well as sulfolane stripper, lasted fewer than four years. As a result of upgrading their maintenance strategy, the HVTS cladding is still in excellent condition after eight (or more) years in service.

Key Benefits of IGS HVTS Cladding:

- Longevity: HVTS Cladding has demonstrated remarkable longevity, outperforming conventional coatings by a significant margin. At Sendai, IGS Japan’s cladding remained intact and effective after eight years of service, while a previous vendor’s coatings had failed and peeled off during the four-year period.

- Operational Excellence: By reducing unplanned shutdowns and extending maintenance intervals, HVTS Claddings contribute to improved operational efficiency and productivity. Additionally, IGS Japan’s commitment to safety and quality has been recognized by the plants, with the company receiving safety awards for their exemplary work.

- Asset Protection: HVTS cladding provides robust protection against corrosion, erosion, and wear, extending the service life of critical assets and minimizing the need for costly replacements or repairs.

Implementation, Results and Further Applications

IGS Japan’s collaboration with the energy company began in 2012 with a project at the Okayama, where heavy fuel oil boilers were coated. Following the success of this initial refinery corrosion mitigation project, IGS Japan expanded their services to other facilities, including Miyagi, Kanagawa and Yamaguchi.

HVTS for Refinery Corrosion Mitigation – The Results

At the Sendai refinery, IGS Japan’s HVTS cladding played a crucial role in protecting the CAT Cooler (catalyst cooler) facility, a critical process unit with large-diameter tubes prone to erosion. After four years of operation, only minor portions exhibited wear, while the coated areas remained in excellent condition.

In addition to process units, IGS Japan has also coated heat exchangers and columns at various refineries, contributing to improved asset integrity and operational reliability.

Conclusion of another successful HVTS project

The successful collaboration between IGS Japan and the Japanese leading energy company demonstrates the power of advanced coating technologies in addressing corrosion and erosion challenges in the energy industry. By adopting IGS Japan’s HVTS cladding, the plants have achieved significant improvements in operational efficiency, asset longevity, and overall plant reliability.

As this leading energy company continues to expand its partnership with IGS Japan to other refineries, the company is poised to realize further benefits and solidify its position as a leader in sustainable and efficient refinery operations.

On-site Thermal Spray Coating Services from IGS:

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.