Welding Alternative Achieves 50% Savings in Renewables Conversion

Converting to Renewables

The former refinery in Eastern Canada was performing a site-wide conversion in preparation for firing renewable fuels. The Canadian government was partly financing the conversion. The refinery started processing sustainable aviation fuel (SAF) in summer 2022. Using SAF results in an up to 80% reduction in carbon emissions compared to the traditional jet fuel it replaces over the lifecycle of the fuel.

Upgrading Process Vessel Metallurgy

Two reactors and two drums required a metallurgy upgrade due to new operating conditions. With renewables processing, reactors are susceptible to high temperature free fatty acid (FFA) corrosion, sulfidation, wet chloride corrosion, and stress corrosion cracking.

The drums had possible damage mechanisms including wet CO2 corrosion, wet chlorides and potential NH4HS and NH4CL.

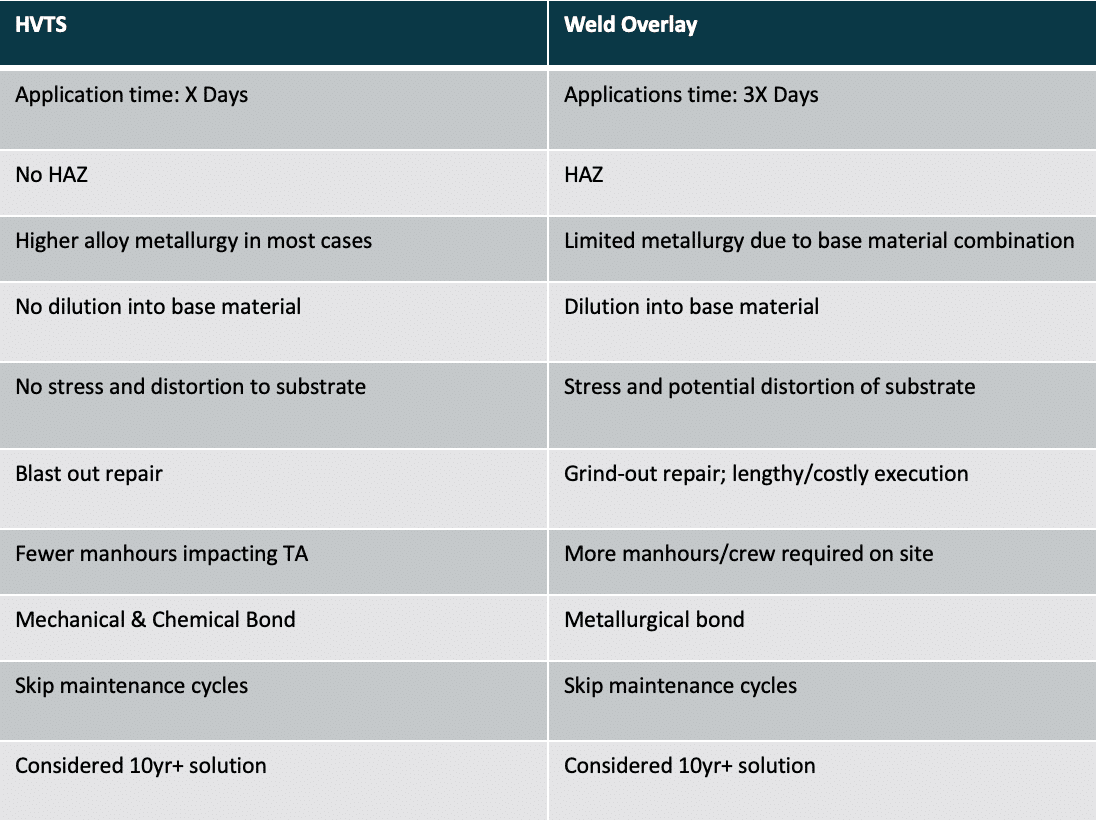

Upgrading the metallurgy can be achieved via automated welding or high velocity thermal spray (HVTS).

Selecting the Solution

The refinery, in conjunction with their EPC, have contracted Integrated Global Services (IGS) to apply HVTS® cladding. Jason Lynn, IGS Asset Integrity Specialist, said: “They saved half of their cost comparing to automated welding and a third of their time. Another reason why they didn’t choose automated welding, was the fact that IGS doesn’t have to preheat the material for the HVTS® application. This was important as the facility is in Arctic conditions.”

“The facility appreciated the fact that IGS could work turnkey. They didn’t want to have multiple vendors performing different tasks with one group doing preheating, another group welding with a third group potentially doing the post weld heat treatment.”

IGS worked turnkey and performed blasting, provided ventilation, applied thermal spray and inspection services.

Furthermore, much higher deposition rates, without dilution or needed “butter” / intermediate layers to achieve surface chemistry, make HVTS® a better choice over welding applications.

HVTS vs Welding

Material Science

IGS designed and specified two different alloys for the drums and the reactors. NiCroMoXX type material has been specified for the reactors due to its excellent resistance to chloride corrosion, SCC and sulfidation. For the drums, a NiCroMoWXX material was specified for its proven corrosion and erosion resistance.

Prequalifying the Solution

The EPC, asset owner and the licensor required a comprehensive pre-qualification and adherence to a tight engineering standard to govern the quality of the cladding applied and ensure that the HVTS protection would hold up against the new harsh corrosion mechanisms. Tests were performed at the IGS state-of-the-art Laboratory in Richmond, Virginia to alleviate any concerns.

Iain Hall, IGS CTO, said: “While material selection is important, it is only a small part of the technical package required to ensure durable long-term performance in claddings systems. Careful attention to surface preparation and accessibility, utilization of a high velocity process and critical parameter control is necessary to ensure homogenous alloy cladding with the right mechanical properties. It also takes more than a coupon to qualify an application. Management of environmental conditions and monitoring of field quality control with real time production test plate assessments is also required.”

Project Execution

IGS delivered an engineering package, including the project plan, method statement, inspection test plan, project safety analysis, risk mitigation plan and the job specific safety data sheets.

The project was completed in over ½ the time the plant estimated weld metal overlay would take to execute.

Inspection

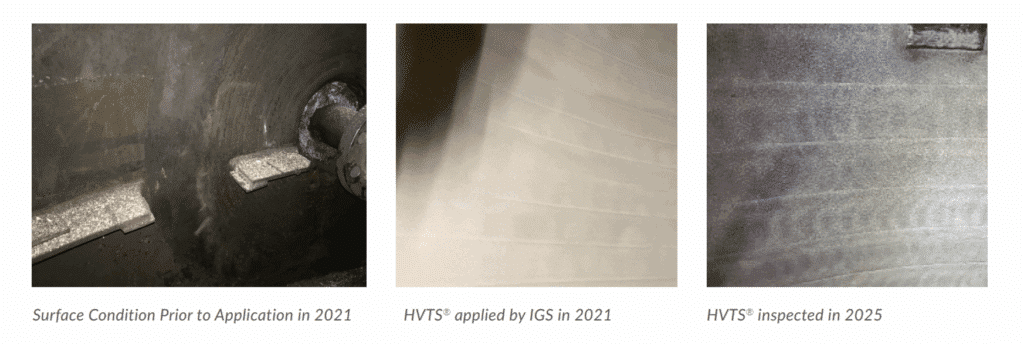

IGS, together with the refinery and the independent inspector have carried out a thorough cladding inspection 4 years after its initial application. All HVTS® cladding, including the tie-in areas, was found to be in as-applied condition with no signs of delamination, degradation or metal loss.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.