Why an Alloy Upgrade is the Best Solution to Crude Unit Overhead Corrosion Control

Overhead Corrosion in Refineries

Corrosion in the overhead section of pressure vessels, known as overhead corrosion, is a significant challenge the energy industry faces. This type of corrosion can occur in both primary units, such as crude distillation units (CDU) and vacuum distillation units (VDU), as well as secondary units like absorbers, fractionators and strippers. Understanding the causes and mechanisms of overhead corrosion is crucial for implementing effective mitigation strategies.

What Causes Crude Unit Overhead Corrosion?

The driver of overhead corrosion is the presence of “bad actors” such as salts and organic acids (TAN – Total Acid Number) in the feedstock.

As the feedstock is heated during the process, various salts, including sodium chloride, magnesium chloride, and calcium chloride can undergo hydrolysis, producing hydrogen chloride (HCl) gas. This HCl gas can then condense in the overhead section of the column, leading to the formation of aqueous hydrochloric acid, which is highly corrosive to the equipment. Reducing the salt content in the crude oil through desalting processes can mitigate the potential for HCl formation and subsequent overhead corrosion.

However, substances in the feed such as sulfur, and organic acids, for example naphthenic acids, cause corrosion by themselves and contribute to the corrosive environment in the overhead section, leading to accelerated degradation of the equipment.

Ammonia, amines, and caustic are often used for desalting, but the resulting compounds like ammonium chloride (NH4Cl) and amine hydrochlorides can also cause corrosion.

Additionally, dry corrosion can occur due to salts and other corrosive compounds deposition on the metal surfaces. These deposits can create localized areas of high acidity, leading to accelerated corrosion rates. The temperature gradient between the hot and cold sections of the overhead system can also contribute to the formation of these corrosive deposits.

Other Contributing Factors to Crude Column Overhead Corrosion

Another contributing factor to overhead corrosion is the presence of other corrosive substances in the feed such as sulfur, and naphthenic acids. Ammonia, amines, and caustic are often used for desalting, but the resulting compounds like ammonium chloride (NH4Cl) and amine hydrochlorides can cause corrosion by themselves. Naphthenic Acid can also contribute to the corrosive environment in the overhead section, leading to accelerated degradation of the equipment. Additionally, dry corrosion can occur due to salts and other corrosive compounds deposition on the metal surfaces. These deposits can create localized areas of high acidity, leading to accelerated corrosion rates. The temperature gradient between the hot and cold sections of the overhead system can also contribute to the formation of these corrosive deposits.

Using Metal Alloy Cladding to Stop Crude Unit Overhead Corrosion

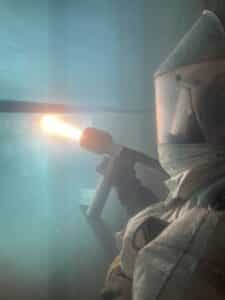

Innovative metal alloy cladding technologies have emerged as promising solutions to combat overhead corrosion on site. High Velocity Thermal Spray (HVTS) cladding systems, in particular, offer superior protection against overhead corrosion compared to traditional materials and methods. HVTS cladding involves atomizing a corrosion-resistant metal alloy and propelling the droplets at high velocity onto a substrate, typically carbon steel. The resulting cladding forms a mechanically superior and corrosion-resistant barrier. Recent advancements in alloy modification have addressed previous limitations, eliminating inter-particle porosity and enhancing bond strength.

Proving Performance: A Corrosion Control Study

In contrast, modified NiCrMo-XX alloy HVTS claddings demonstrated superior resistance to overhead corrosion. These systems, designated as IGS 5xxx, showed no evidence of chlorine penetration, material degradation, or corrosion at the substrate interface. The claddings remained well-adhered, with bond lines free of corrosion scale or chlorine presence. A novel Metal Reinforced Polymer (MRP) system, utilizing a titanium alloy cermet scaffolding infused with a high-temperature polymeric material, also exhibited excellent corrosion resistance in the overhead environment. This hybrid system, known as MRP, passed all corrosion tests without any signs of degradation or media penetration.

The success of these modified alloy claddings in resisting overhead corrosion can be attributed to their optimized microstructure and composition. By eliminating interconnected porosity and enhancing interfacial adhesion, these systems effectively prevent the ingress of corrosive species to the underlying substrate.

Alloy Cladding in Narrow Overhead Vessels

Implementing HVTS cladding with modified alloys or MRP systems offers a robust solution to mitigate overhead corrosion. These technologies significantly extend the lifespan of pressure vessels, reduce maintenance costs, and minimize unplanned shutdowns due to corrosion-related failures, as witnessed by multiple IGS customers.

For many years, these technologies were limited to vessels with larger diameters. In recent years, IGS developed robotic systems that can be field-deployed and can inspect and clad vessels starting from 20’ (500 mm) in diameter.

The application of advanced metal alloy cladding technologies represents a paradigm shift in combating overhead corrosion in refineries. By leveraging these innovative materials and application methods, asset managers can ensure greater reliability, efficiency, and longevity of their critical infrastructure. Contact us today to book your project.

Speak to an overhead corrosion advisor today.

More corrosion and erosion management articles from Integrated Global Services:

CO₂ Corrosion Prevention and Control in Oil and Gas Production

How to Prevent Microbially Influenced Corrosion (MIC) with On-Site Alloy Upgrade

Why is High Emissivity Coating Durability Important in Fired Heaters?

Strategies for Preventing Internal Pipeline Corrosion in the Energy Industry

Flue Gas Dew Point Corrosion Mitigation: Alloy Upgrading Techniques

Mitigating Metal Dusting Corrosion in Ammonia and Methanol Reformers

Combating Flow Accelerated Corrosion in Power Plants with IGS HVTS Technology

Protecting Hydropower Turbines from Corrosion with HVTS Coatings

Protecting Offshore Wind Turbines – Splash Zone Corrosion

The Critical Role of High Emissivity Coatings in Space Exploration

Organic Coatings in Pressure Vessels: Internal Coating Failure Analysis

How to Stop Corrosion on Your Refinery Distillation Column

Causes of Boiler Corrosion and Benefits of Boiler Tube Coating

5 Common Causes of Refractory Failure and How to Fix Them

Boiler Tube Leaks Prevented with Proactive Maintenance

Understanding Oil & Gas CO2 and NOx Emissions, and the Science Behind Reducing Them

A Guide to Amine Stress Corrosion Cracking in Oil & Gas Processing