U.S. Environmental Protection Agency Takes Action on NOx with a Good Neighbor Provision

The Good Neighbor Provision (GNP) aims to reduce NOx emissions from power plants, refineries, and industrial facilities from upwind states. These states currently prevent downwind states from attaining and maintaining the 2015 Ozone NAAQS.

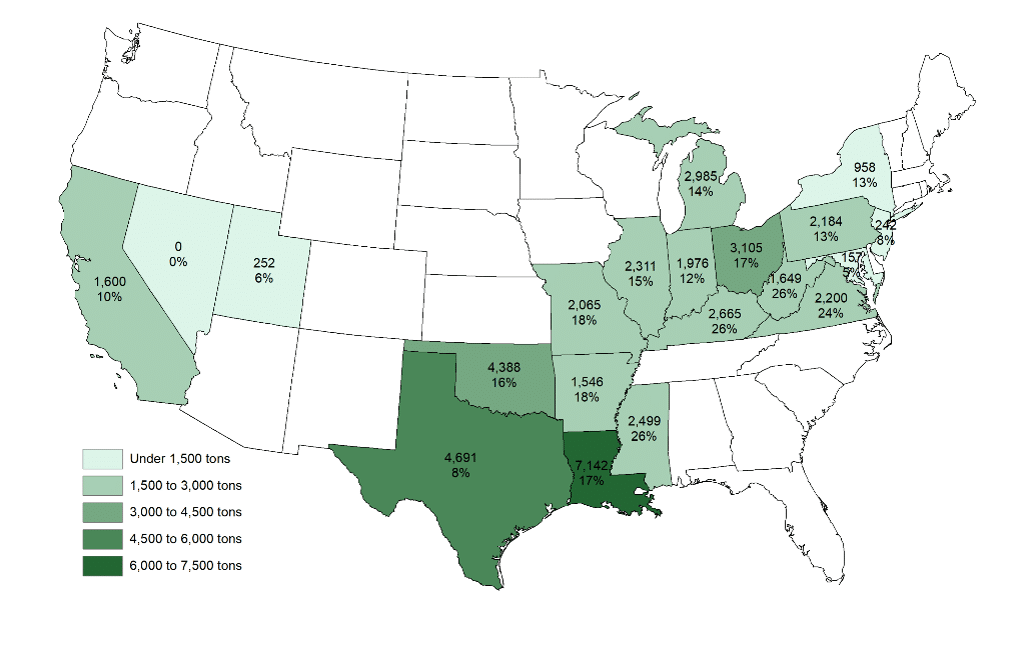

23 states affected by the GNP include Alabama, Arkansas, California, Illinois, Indiana, Kentucky, Louisiana, Maryland, Michigan, Minnesota, Mississippi, Missouri, Nevada, New Jersey, New York, Ohio, Oklahoma, Pennsylvania, Texas, Utah, Virginia, West Virginia, and Wisconsin.

GNP Emission Reduction Strategies for Industrial Applications

If the design capacity is greater than 100mmBtu/hr, then the facility will likely need to install or optimize their flue gas treatment system, an SCR or an SNCR.

SCR Efficiency

SCR efficiency problems lead to poor NOx removal, high-pressure drops, poor ammonia mixing, and cost plants millions of dollars annually.

This results in system derates and forced outages to clean the catalyst face. Every day the facility is in outage can cost the company approximately $1M in lost production. In addition, the costs of shortened catalyst life, lost production during derates, and excessive ammonia usage contribute to an average $3M + annual cost due to this buildup.

With the GNP plan in place, it is crucial to maximize SCR efficiency.

SCR Efficiency Solutions

Integrated Global Services (IGS) deliver a comprehensive approach to SCR Efficiency, including:

- Lower SCR Buildup with Refractory Encapsulation

- Extend Catalyst Life with Particle Filtration Screens

- Mixing Plate System

- Online SCR Cleaning

DeNOx Emission Control Equipment: How to Solve Operational Challenges

Watch this webinar live (4th April 2023) or on-demand to learn how to improve SCR efficiency. Andrew Kline, SCR efficiency SME, said:

“In this webinar, we will focus specifically on issues associated with flue gas treatment systems and explore comprehensive root-cause solutions to address these challenges to maximize production rates and uptime while simultaneously decreasing emission output.”

Case Study: SCR Efficiency in SMR Optimized

This study highlights an application at a Steam Methane Reformer on the West Coast of the United States, where the facility suffered from SCR efficiency problems. This was primarily due to fibrous material, mostly refractory fibers that have broken free from degradation over time, plugging the face of the catalyst, causing poor NOx removal, high pressure drops, and poor ammonia mixing. Continue reading…