IGS TUFFss ONLINE TSA - Thermal Spray Aluminum Coating

Thermal Spray Aluminum (TSA) Application During Plant Operation

IGS TUFFss ONLINE TSA solution to prevent corrosion under insulation (CUI), corrosion on sweating equipment, and atmospheric corrosion is the safest way while the plant is in operation.

TSA (Thermal Sprayed Aluminium) provides lasting (>20 years) corrosion protection by acting as a barrier coating, passivating the surface.

Plant operators no longer need to make tradeoffs between turnaround duration and asset integrity as IGS TUFFss ONLINE TSA can be safely applied all year round, between shutdowns and turnarounds. Developed in a 2-year R&D program with Royal Dutch Shell, IGS has validated live-plant applications at Shell Pearl and Nigeria LNG/Royal Dutch Shell, among others.

Performing TSA Safely on Sweating Equipment while Your Plant is Operating Means:

- Zero impact on turnaround work

- Asset integrity scopes of work are no longer limited by turnaround duration

- Climate controlled habitats allow for year-round TSA application

- Consistent, controllable quality of application environment

- Mitigates accelerated corrosion of unprotected sections of a process line enabled by complete line protection in a single project

- Effective solution for piping systems with high humidity, temperature differentials, or surface condensation

Online Thermal Sprayed Aluminium Coating TSA

Safe Application during Plant Operation

For TSA to be safely applied online, several issues have been resolved, including process-specific safety procedures, temperature, and humidity. The IGS TUFFss Online TSA solution includes enhanced application processes and procedures, sealed safety enclosures, humidity and temperature control, (negative) environmental pressure control, and a fully automated safety shutdown system for the coating and abrasive blasting processes.

Everything is custom-made and combined in ways unheard of, meeting the highest standards in the industry.

IGS TUFFss Online TSA

Automatic Shutdown System

The emergency shutdown system continuously monitors the entire work area and surroundings. The system provides digital, audible, and visual warnings in case of leak of gasses, pressure loss, or any other parameter deviation.

This in turn enables an almost instantaneous automatic termination of any work and equipment inside or outside the habitat, including, but not limited to, welding, grinding, power, grit blasting, TSA, HVAC, and dust collection.

The Role of Online TSA – Thermal Sprayed Aluminium Coating

Aging Plants Require Work between Turnarounds

Equipment within many refineries, petrochemical plants, and other facilities is now a lot older. Pipes, vessels, and other process equipment face rapid deterioration of their original non-optimal corrosion protection. Atmospheric corrosion is an especially important issue for coastal plants. Sweating equipment, such as chilled lines and cold service piping, is particularly vulnerable due to continuous moisture exposure.

CUI Problem: Evaluating Alternatives

Repainting the piping with paints and coatings may also be a viable option. However, these paints would still need to be inspected and usually reapplied every 5-10 years. Thermal Spray Aluminium (TSA) lasts over 20 years in service and is especially effective on sweating surfaces where traditional coatings fail to adhere properly or deteriorate quickly.

About IGS Online TSA Coating

By providing clients with online TSA application, IGS enables the plant to move these projects out of their shutdown scope, allowing other key value adding maintenance and process enhancement projects to take place and more plant uptime / productivity.

Online Application of TSA Coatings on Sweating Pipes

With our expertise in delivering onsite solutions to downstream petrochemical plants IGS are uniquely positioned to provide engineered thermal spray solutions. We are the first to apply TSA coatings on live plant, on sweating pipes, with condensation on the surface.

Application of Thermal Sprayed Aluminium online requires experienced and knowledgeable operators and project managers.

TSA Advantages

TSA is a tried and trusted corrosion barrier technology designed to stop corrosion under insulation and to protect the external surfaces of process pipework and equipment for extended periods (more than 25 years). Thermal Sprayed Aluminium has been used in the downstream petrochemical industry for more than 50 years.

TSA works by effectively isolating the substrate material (typically carbon steel) from the corrosion environment (electrolyte or conductive liquid), acting as a protective corrosion barrier, to break the corrosion cycle. In addition, Thermal Sprayed Aluminium provides secondary protection of the carbon steel as a sacrificial anode.

The Aluminium will galvanically corrode in preference to the Carbon Steel substrate due to its lower nobility. So, if localized mechanical damage occurs to the TSA coating, there is still galvanic protection against pitting corrosion of the carbon steel.

The Application of Thermal Sprayed Aluminium Coating

The application standard of TSA is critical to the success of the applied coating as a long-term solution against Corrosion Under Insulation. The process must be carefully monitored and controlled, to manage the application standard and quality. A robust quality control process and inspection protocol is crucial.

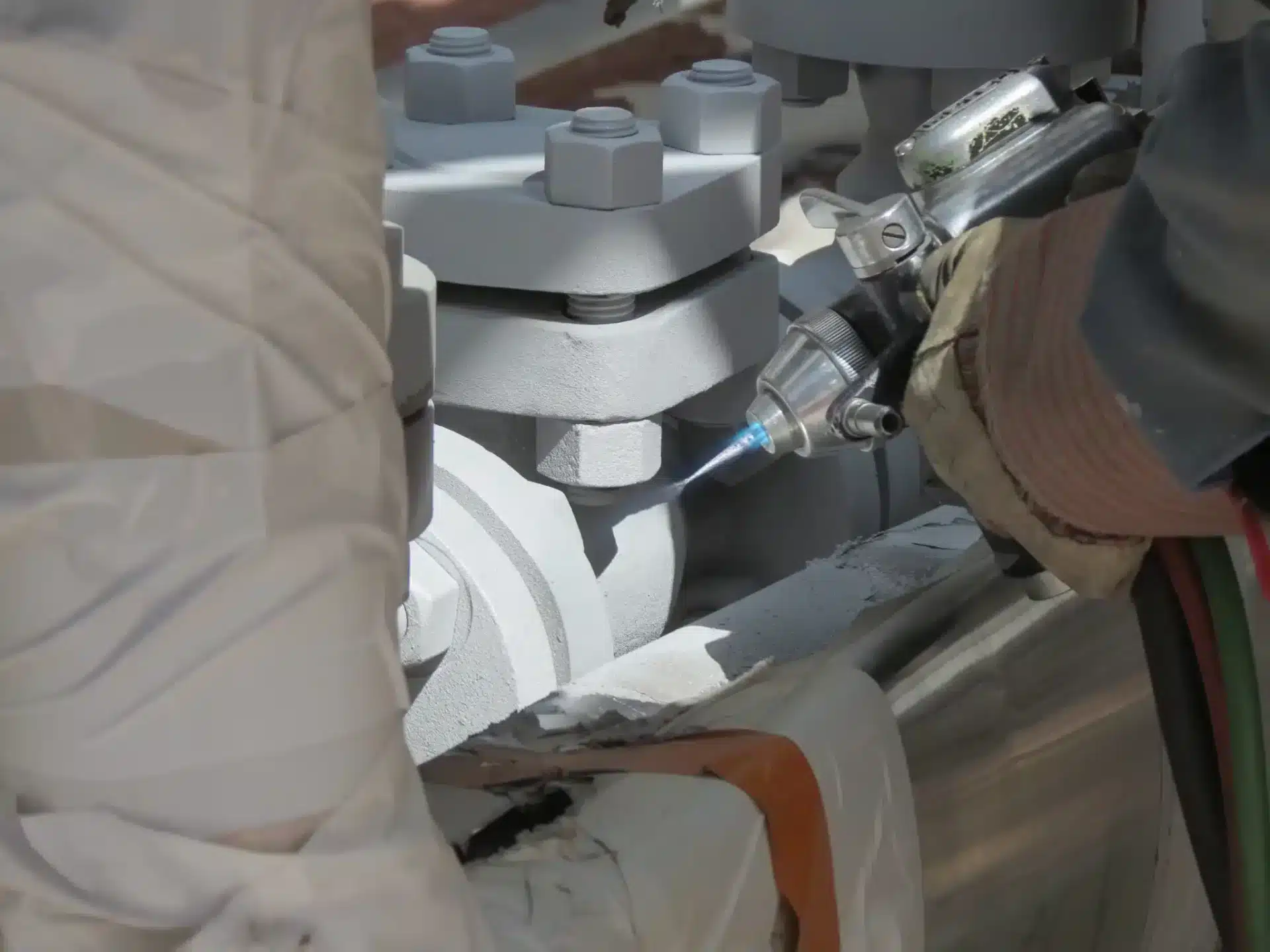

Thermal Sprayed Aluminium coating requires thorough surface preparation, to a white metal (SA3 or NACE 1) cleanliness standard and an average surface roughness of typically 75 to 125 microns (3 to 5 mils), this is achieved through grit blasting which is typically carried out with an open blasting system.

The application of TSA is carried out with a standard thermal spray process, either using twin wire arc spray or flame spray systems, according to NORSOK M-501 and ISO 2063.

Both of these processes create a significant amount of dust and debris, typically the application is carried out during a shutdown, when the plant is offline.

Many downstream petrochemical processing plants have CUI mitigation programs with the application of TSA to protect large areas of the plant, by carrying out these applications during a shutdown the plant is limiting the opportunities to carry out other work and dramatically increasing the scope and schedule of the shutdown/turnaround.

For this reason, IGS has developed containment and application methods to safely apply TSA online.

Substrate Protection for more than 25 years with TSA

Despite the higher initial costs, TSA selected by operators due to the comparative life cycle cost or cost of ownership of the applied system and the achievable return on investment. When the application is properly controlled a Thermal Sprayed Aluminium coating will protect the substrate for more than 25 years, whereas an organic or non-metallic conventional coating system will typically require replacement or maintenance every 5 years. It means five (5) applications of the conventional coating system compared to one (1) application of Thermal Sprayed Aluminium over a 25-year cycle, leading to savings in maintenance, labour and materials. In addition, Thermal Sprayed Aluminium is a robust metallic material, resistant to impact damage and further still will galvanically protect the substrate if locally damaged.

How to Increase the Speed of Maintenance and Maintain Production Capacity?

Maintenance and Operations Managers are under pressure to increase the maintenance speed not to lose many of the production facilities or at least the production capacity. Thus, they look at doing the critical maintenance while the plant is online – in other words, without shutting it down. That way, they will be able to reach their maintenance goal and maintain uptime at the same time.

As equipment within refineries, petrochemical plants, and other facilities continues to age, the demand for maintenance solutions that can be applied safely all year round is growing. Plant operators are looking to IGS to utilize their global footprint and experience to deliver innovative solutions safely and efficiently.

Conclusion

Preventing shutdowns and providing the work outside of turnarounds eases the pressure off the maintenance and operations teams, who can continue production while crucial maintenance work is being simultaneously carried out.

Several IGS TUFFss ONLINE TSA projects are being commissioned with refineries and petrochemical sites, paving the way for more uptime in aging facilities. In particular, sweating equipment that typically suffers from premature coating failure is now protected for decades with minimal disruption.

Contact us today to learn more about IGS TUFFss Online TSA and how it can help your facility extend asset integrity outside of your turnaround schedules – especially for sweating equipment.

I’m here to help

Colin Bateman

IGS Subject Matter Expert

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.