IGS Metalspray® Pipe ID Rover: Advanced Internal Corrosion Prevention for Oil and Gas Pipelines

Unlocking Innovation in Corrosion Control

Transporting untreated wet gas poses significant corrosion risks to pipelines. The presence of corrosive contaminants such as H2S and CO2 in oil and gas pipelines can severely damage key pipeline assets such as finger slug catchers, flare lines, and wet gas pipes by the corrosion of carbon steel surfaces. This results in leaks, loss of containment, and costly unplanned shutdowns.

At IGS, we understand the demand for effective corrosion control to maintain pipeline integrity and operational efficiency.

Causes of Internal Corrosion in Oil and Gas Pipelines

H2S and CO2 corrosion is a critical concern for the oil and gas industry’s offshore operations, particularly in regard to internal corrosion control in pipelines.

Understanding the Challenges and Limitations of Existing Prevention Methods

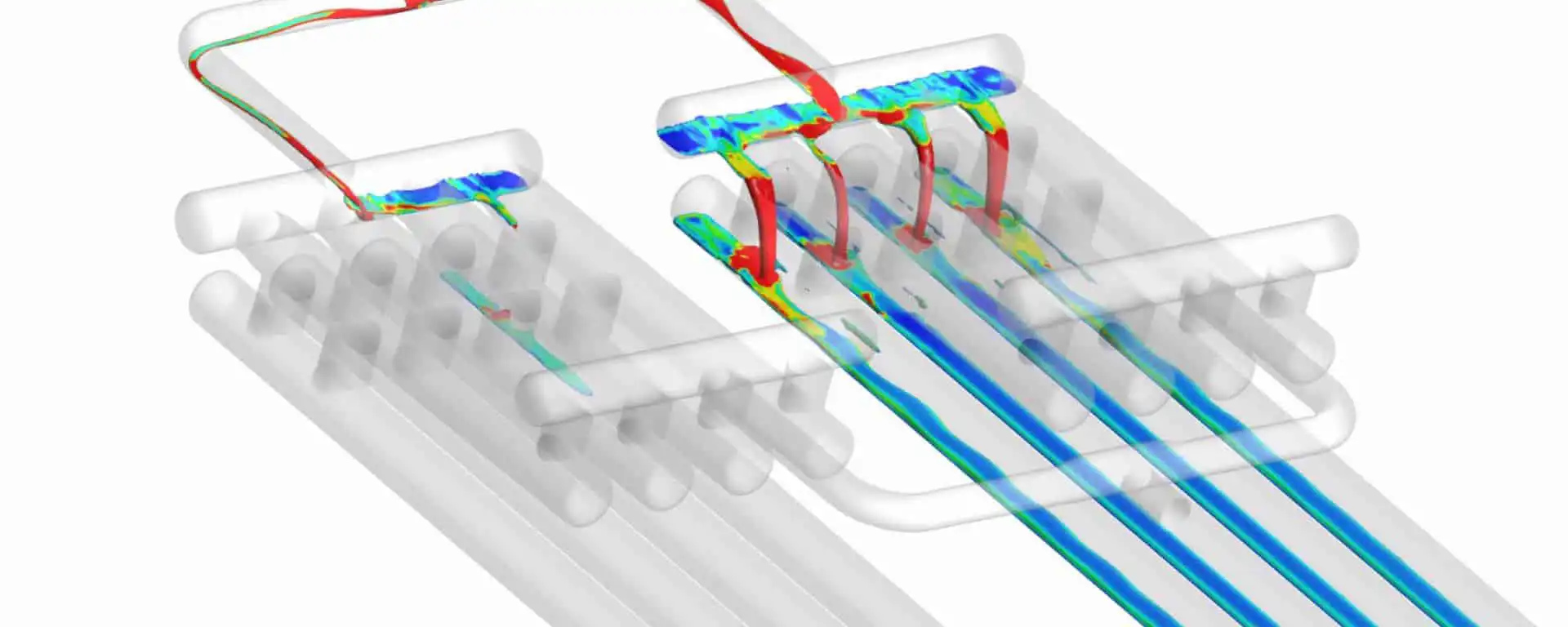

Corrosion in wet gas pipelines arises from various mechanisms, including CO2 corrosion (sweet corrosion) and H2S corrosion. CO2 dissolves in water, forming carbonic acid that attacks the pipe wall, while H2S dissociates to form sulfuric acid, leading to pitting. The oxygen content, corrosive by-products, and contaminants introduced during production operations further contribute to internal corrosion.

Watch this on-demand webinar

How can a field-applied Metalspray PipeID Rover protect pipeline sections and weld seams from corrosion?

Introducing IGS Automated Metalspray® Pipe ID Cladding

Integrated Global Services (IGS) introduces an advanced corrosion control technology for oil and gas pipelines, representing a major leap forward for internal corrosion protection strategies.

A Breakthrough Solution for Pipeline Corrosion Protection

By offering a no-man-entry, field-applied alloy upgrade for pipelines, slug catchers, and flare lines, this cutting-edge solution addresses the challenges of wet CO2 corrosion and internal corrosion in pipelines with unparalleled precision.

Field-Applied Alloy Upgrade – An Innovative Solution for Pipeline Corrosion Control

The IGS Metalspray® PipeID Rover system leverages the proven effectiveness of alloy upgrades to combat the pervasive issue of corrosion, extending the operational life and reliability of key pipeline assets with a field-applied, no-man-entry method.

How does the IGS Metalspray® Pipe ID Rover Control Internal Corrosion?

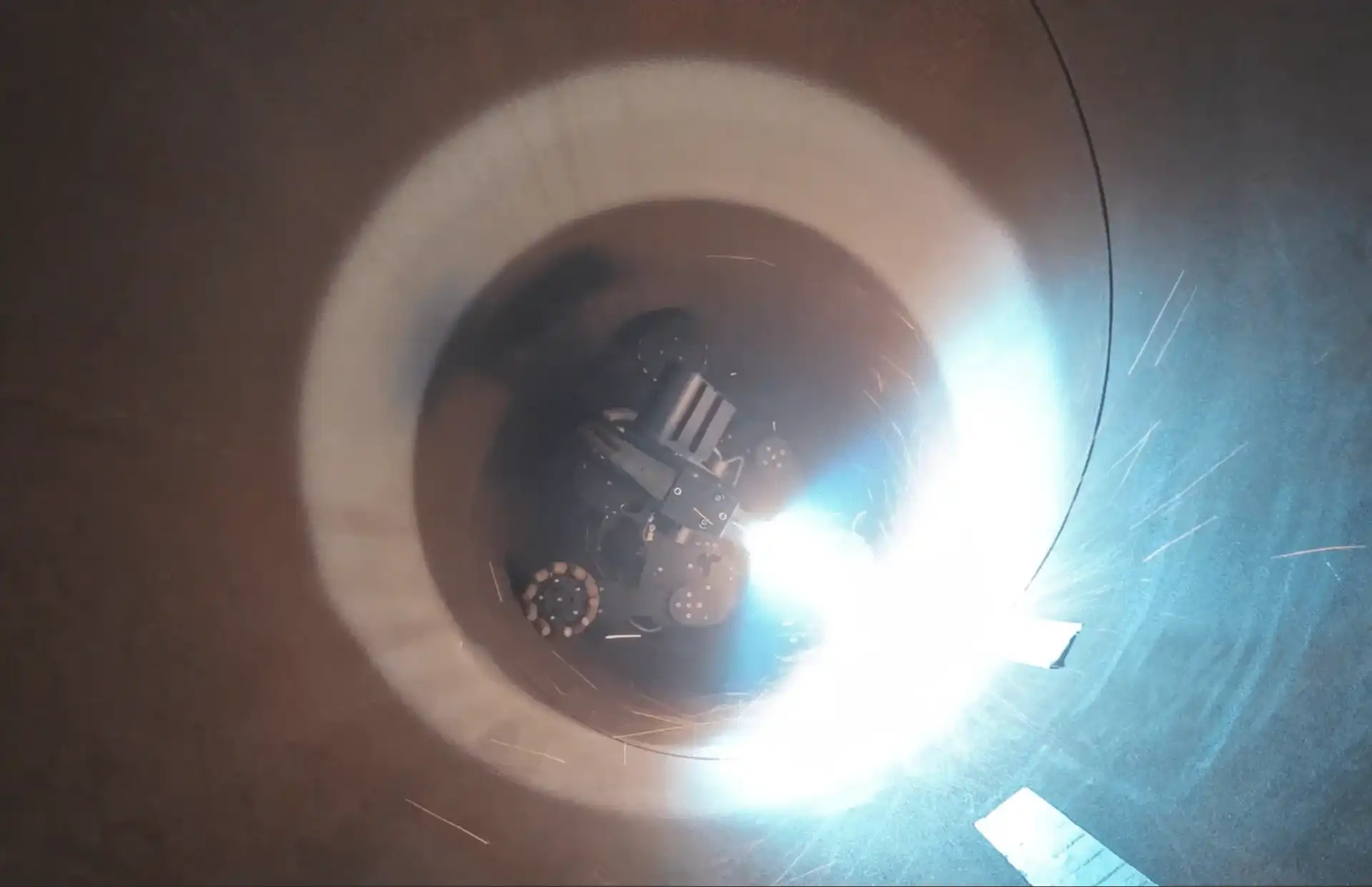

The Metalspray® PipeID Rover is a revolutionary self-propelled system designed for internal coating and corrosion protection of flare lines, finger slug catchers and wet gas pipelines. It navigates through pipelines, applying a durable alloy coating to interior surfaces without the need for direct human intervention. This approach ensures comprehensive surface preparation, alloy application, and quality control in environments previously considered challenging or impossible to treat effectively.

Key Benefits of the Metalspray® Pipe ID Cladding

Targeted Pipeline Corrosion Protection and Beyond

Targeted Protection: 360-degree access to critical areas ensures comprehensive coverage, protecting bottom sections, low spots, and weld seams.

Pipe ID Corrosion Mitigation: Alloy upgrades restore and reinforce affected areas, significantly extending the asset’s life.

Laser Integrity Scans and Visual Documentation: Real-time scans provide essential documentation, ensuring quality and accountability.

Safe Operation in Hazardous Environments: Designed for operation in hazardous wet gas environments, eliminating the need for confined space entry.

Cost-Effectiveness: Maximizes capital efficiency, avoiding expensive replacements and providing a financially viable corrosion prevention solution.

The IGS Metalspray® Pipe ID Rover In Action

A Comprehensive Corrosion Control Strategy

By halting further damage and mitigating pipeline corrosion, our rover becomes more than a tool; it becomes a comprehensive strategy against CO2 and H2S corrosion. The solution supports operators in strengthening offshore infrastructure, ensuring uninterrupted production, and protecting their investment in pipeline systems.

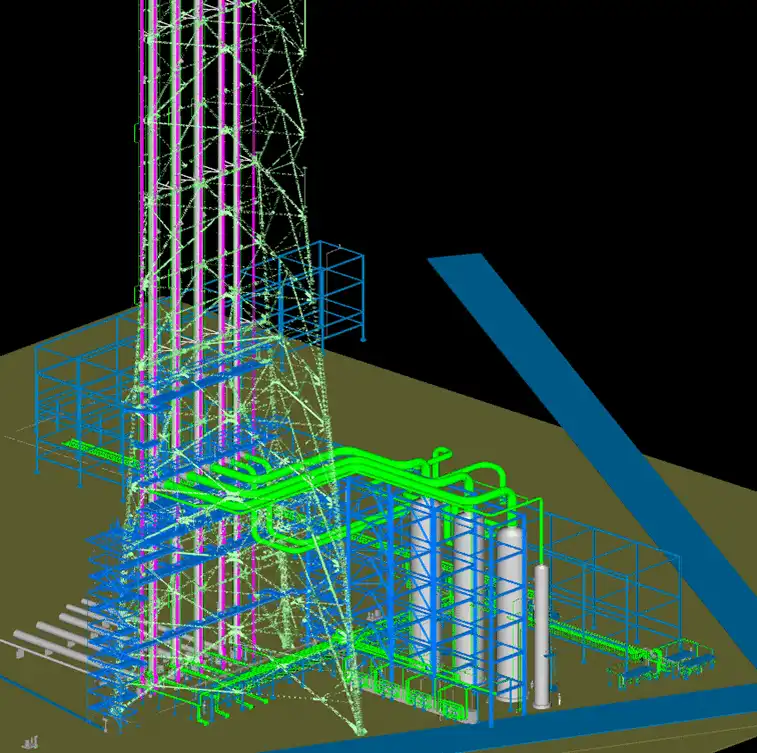

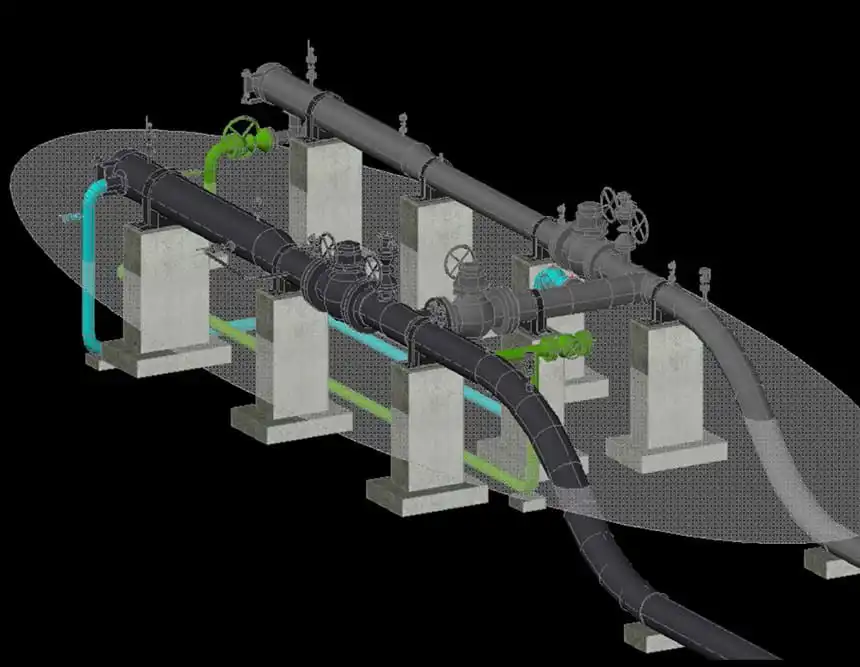

Addressing Finger Slug Catcher Corrosion

A Pioneering Approach

Slug catchers, critical components in upstream oil and gas infrastructure, often suffer from internal corrosion due to the continuous presence of liquid hydrocarbon phases. The IGS Metalspray® Pipe ID Rover addresses this challenge, providing a field-applied alloy upgrade for finger slug catchers, ensuring their prolonged operational lifetimes.

Enhancing Flare Line Durability

Unveiling the Metalspray® PipeID Rover System

Flare lines, crucial in managing excess gases, face constant threats from corrosion induced by H2S, CO2, and other corrosive agents. The Metalspray® PipeID Rover system offers a revolutionary solution, enhancing flare line durability through field-applied alloy upgrades.

Learn more about mitigating flare line corrosion to enhance durability

Advanced Corrosion Control for Wet Gas Systems

IGS Metalspray® Inside Pipes

Transporting untreated wet gas to the gas treatment/flaring facilities is often required. Despite being economically attractive, this process poses significant corrosion risks, particularly from H2S and CO2, to piping. Understanding and mitigating this corrosion is imperative for maintaining pipeline integrity and operational efficiency.

Why Choose IGS?

Pushing the Boundaries of Internal Corrosion Control Technology

At IGS, we’re committed to providing innovative solutions that meet the unique challenges of the oil and gas industry. Our Metalspray® PipeID Rover system is just one example of how we’re pushing the boundaries of technology to protect and enhance critical infrastructure. With a track record of success and a team of experts dedicated to excellence, we’re here to ensure your operations are safeguarded against the threats of corrosion.

Choose IGS for cutting-edge corrosion prevention. Safeguard your operations with our advanced technologies.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.