Cetek Coatings for Process Tubes

Does tube scale & tube metal temperature limit your fired heater performance?

Is your fired heater limited by bridge wall temperature, tube metal temperature or firing duty? The cause could be excessive fouling/scale formation on the radiant tubes.

Cetek’s technology addresses all these issues and brings the tubes back to an as-new condition. The Thin Film High Emissivity Cetek Coatings ensure that the tubes remain in this clean state for an extended period of time.

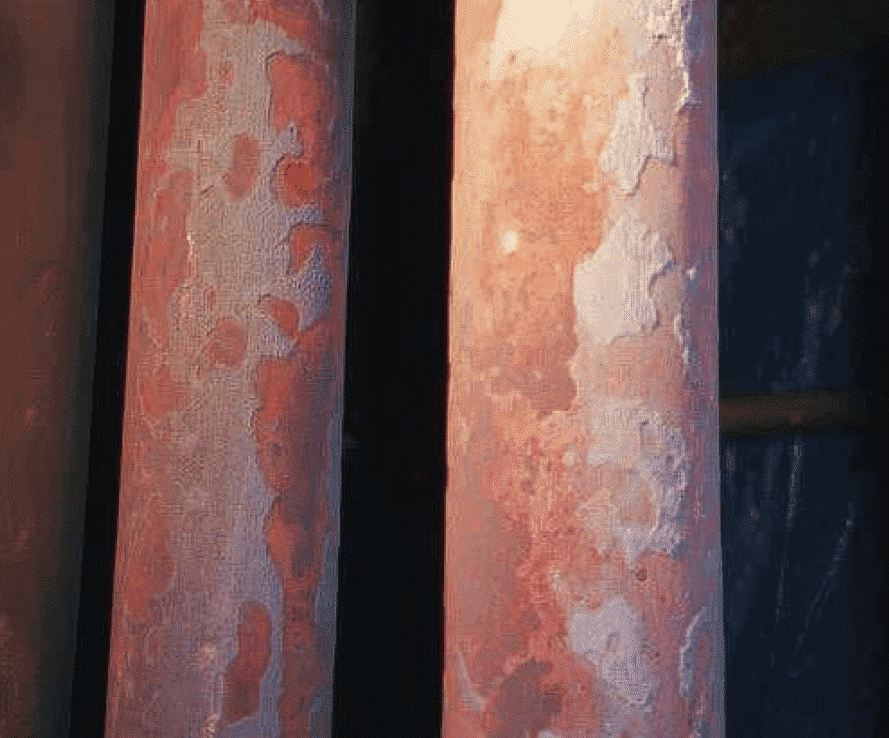

Process Tube Oxidation and Carburization Protection

Cetek thin film coatings provide a durable, protective, thin-film layer on the outer surfaces of process tubes, which prevents oxidation, corrosion, and carburization of the metal and maintains the tube thermal conductivity coefficient close to new tube conditions.

How Cetek Process Tube Coatings Deliver Maximum Heat Transfer

Oxidation and scale formation on the outer surfaces of process tubes reduces conductive heat transfer, resulting in low production rates and/or excessive fuel consumption. Cetek’s High Emissivity Thin Film Coating system ensures maximum conductive heat transfer for the process.

Significantly Improve Reliability

Layers of fouling/scale prevent accurate determination of tube metal temperature, reducing the reliability of those measurements. Because the thin layer of Cetek Coating provides a consistent temperature differential between the outside surface and the metal tube, the reliability of tube metal temperature determination is improved significantly.

I’m here to help

Larry Emch

IGS Subject Matter Expert

Payback within 6 Months

Cetek High Emissivity Coating Stops Oxidation & Scale of Radiant Tubes

Benefits of Cetek Coatings for Process Tubes

Corrosion and carburization result in metal loss and reduced service life.

Cetek’s coatings provide significant benefits in the form of:

Oxidation Prevention

Oxidation and scale formation on the outer surfaces of process tubes reduces conductive heat transfer, resulting in low production rates and/or excessive fuel consumption.

Cetek’s High Emissivity Coating system ensures optimum maximum conductive heat transfer for the process.

Carburization Prevention

An industry trend to operate fired heaters more efficiently, at lower excess oxygen levels, to save fuel and reduce CO2 emissions has increased the potential for carburization of external surfaces of radiant section tubes.

This leads to grain boundary penetration of carbon, carbide formation, embrittlement of the surface, crack formation and loss of metal.

The result is a reduced service life of the radiant tubes.

Radiant tube external surfaces were protected from carburization by Cetek Ceramic Coatings in applications in major refineries around the globe.

In each case, the life of the coating was at least 10 years, during which time there was no evidence of carburization of outer tube surfaces.

Extension of Service Life

If process tube life is limited by wall thickness reduction caused by oxidation or carburization, Cetek’s High Emissivity Coatings will address this limitation and extend tube life.

Reliable Determination of Tube Metal Temperature

Measuring tube metal temperatures is vital to the reliable operation of fired heaters. The presence of oxidation and layers of scale on the tube surfaces interferes with the accurate determination using IR thermography, or optical pyrometers, since the external surface of the fouling layer could be significantly higher than the actual metal temperature.

Cetek’s high emissivity coatings prevent oxidation and scale formation and provide a consistent temperature gradient between the coating surface and the metal. This allows an accurate determination of the actual metal temperature and a return to reliable operation.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.