CatFlow® Catalyst Screens for SCRs

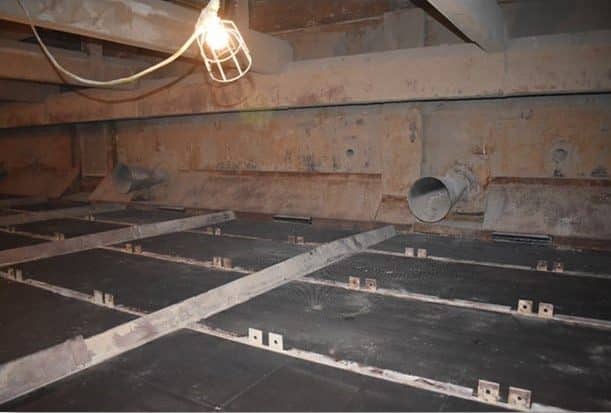

The newest cleaning method in SCRs is the patented CatFlow® Screen offered by IGS. This screen system is designed to replace the catalyst screen located above the catalyst module in a coal power plant. The CatFlow® screen:

Reduced Buildup

Studies have shown that the CatFlow® screen itself helps reduce buildup alone. This is achieved in two primary ways. First, the smooth surface of the screen gives less surface area for the ash to “cling” to, allowing the flue gas to sweep the ash away naturally.

Normalized flow across the catalyst surface

Secondly, these screens act as localized flow aid, normalizing flow across the catalyst surface, allowing the flow to pull ash through.

The screens will increase the reactor’s cleaning efficiency and offer superior protection to the catalyst.

IGS CatFlow® Screen and air cannon installation, compromise a 95% SCR Guarantee. The screen offers superior protection and enhances online cleaning equipment.

CatFlow® Screens Improve Air Cannon Performance

The NoNOx™ CatFlow® Screen dramatically improves the performance of air cannon cleaning in three ways.

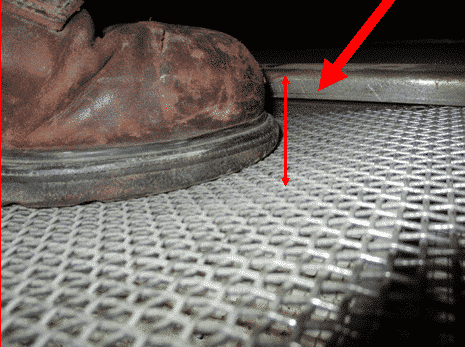

Firstly, because of the smooth surface of the CatFlow® screen, it takes less force to move ash particles across the screen. Think how much easier it is to sweep sand across a carpet instead of a concrete floor.

The smooth surface of the CatFlow® screen is akin to the concrete floor, while the rough surface of a typical mesh wire screen is rough like the carpet. Therefore, as you move further from the nozzle and the blast weakens, the ash sweeper’s blast is still able to sweep the fly ash into the stronger flue gas stream.

The smooth surface of the screen also has less surface area for ash to cling to; think of ash particles on the mesh wire screen akin to dirt trapped in steel wool or the carpet mentioned above, as shown below.

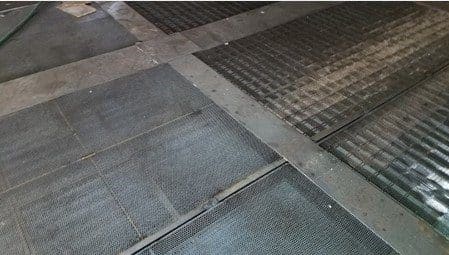

Smooth Screen Surfaces

The smooth surface profile of the CatFlow® Screen has less fluid resistance, which slows the fluid boundary layer formation between the screen and the main blast stream. A fluid boundary layer forms a high-pressure region between the blast and the screen, which causes the blast to be diverted upwards and away from the intended cleaning area.

Due to the fact the CatFlow® Screen slows the formation of this boundary layer, the air cannon blast stays on the surface of the screen longer, providing a greater cleaning depth. Because of these factors, the CatFlow® Screen increases the cleaning performance of air cannons by 25% or more.

These same principles increase the performance of the Sonic Horns as well. Given that the smooth surface requires less force to move particles, the same energy applied by the sonic horn can achieve greater particle displacement, resulting in better cleaning.

Last Line of Defense against Combustion LPA

The CatFlow® screen offers superior protection from Non-combustion LPA and serves as a last line of defense against combustion LPA in the case of a small amount of combustion LPA reaching the SCR.

Non-combustion LPA occurs on the SCR walls, beams, and turning vanes. This buildup often becomes large enough that the buildup’s weight overcomes the cohesive forces that hold it onto the wall and falls onto the catalyst screen. If the catalyst screens are only designed as protection from being walked upon, they will provide little or no protection from non-combustion ash. The hole size of primitive catalyst is larger than the catalyst opening, enabling bisect ash to fall through the catalyst screen and then block it.

Safe and Easy to Use

The CatFlow® screens are designed to prevent this with openings smaller than the catalyst opening, specifically designed to filter out LPA, thereby disallowing these lumps to block the catalyst. These lumps are then broken apart by the air cannon blast, and buildup is avoided.

Lastly, most importantly, the CatFlow® screens are designed specifically with safety and ease of handling in mind. Typical wire mesh screens allow significant deflection when walked on, creating a tripping hazard. In at least one case, this has been documented to directly result in a lost time injury. The rugged nature of the CatFlow® screen’s perforated plate design can eliminate this hazard.

Given the CatFlow® screen’s sturdy design, it also makes removal and reinstallation significantly easier and less time-consuming. This also helps eliminate pinch point hazards during inspection and maintenance.

Free Consultation with IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.