Protecting Carbon Capture Assets from CO₂ Corrosion

Technical Challenges in CCUS Operations

CO₂ corrosion (also known as “sweet corrosion“) poses significant operational challenges to carbon capture facilities. The reaction between CO₂ and moisture forms carbonic acid, leading to carbon steel CO₂ corrosion and structural degradation. This corrosion mechanism can result in:

- Equipment failure

- Process interruptions

- Significant production losses

- Integrity and containment issues

CO₂ Corrosion Mechanism and Variables

Corrosion in carbon capture processes is primarily driven by the presence of water, oxygen, sulfur and nitrogen oxides, chlorides, and other impurities. These factors interact to form acids and reduce the effectiveness of protective films on metal surfaces, such as carbon steel, leading to increased risk of leaks, equipment failure, and environmental hazards. Effective corrosion management requires careful control of water and impurity content, material selection, and process condition.

Key Variables Affecting Corrosion Rates

These quantifiable parameters influence the rate and extent of CO₂ corrosion:

- Operating temperature

- System pressure

- Flow characteristics

- Water chemistry (pH, conductivity, dissolved oxygen)

- CO₂ partial pressure

- Concentration of process impurities (SOx, NOx, O₂)

CO₂ Corrosion Mitigation

Successful CO₂ corrosion mitigation requires surface protection technologies that maintain containment integrity while withstanding high concentrations of CO₂ and process impurities.

Critical Equipment Susceptibility Analysis

High-Risk Components in CCS Systems

Carbon capture facilities exhibit specific corrosion vulnerabilities in the following systems.

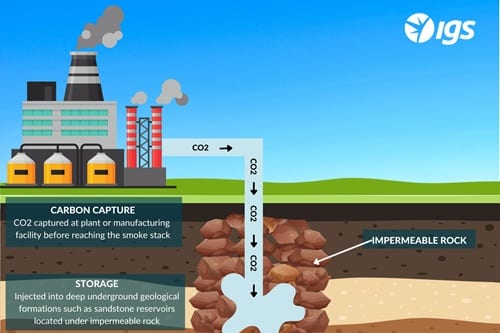

Carbon Capture & Storage (CCS) Infrastructure

- Absorption towers and regeneration units

- High-pressure CO₂ compression systems

- Long-distance transportation pipelines

- Injection wells and underground storage facilities

Process Equipment with Elevated Corrosion Risk

- Regenerator columns in amine systems

- Wet gas handling systems

- CO₂ strippers and reboilers

- Internal piping systems and weld seams

Case Studies in CO2 Corrosion Mitigation

1. Carbon Capture Project on US Gulf Coast

A CCS project required a material solution when the specified coating was determined to be incompatible with the high-temperature calciner environment. Project economics indicated potential losses of $500,000 per day of delay.

Technical Response

- 24-hour mobilization timeline

- Material selection based on temperature, oxygen, and CO₂ exposure parameters

- IGS presented proven HVTS® high-nobility alloy cladding references from similar applications, validating the solution for this carbon capture facility

- HVTS® high-nobility alloy cladding application in two phases

- 80% of critical surfaces completed during the initial phase

Results

Project schedule maintained with projected service life of equipment exceeding design specifications. The HVTS process introduced no material heat input, preventing additional stress to the base material that could initiate corrosion problems in later stages.

2. LNG Plant Regenerator Column

An LNG facility identified failure of conventional thermal spray coating in a regenerator column, with metallographic examination showing micro-cracking and blistering throughout the vessel.

Implementation Strategy

- 10-day mobilization from initial contact

- Removal of failed coating using controlled surface preparation methods

- Application of 40m² of HVTS® cladding meeting NACE and API specifications

- No heat treatment required

- Completed within scheduled outage window

Results

Equipment returned to service with integrity verification via DFT, adhesion testing, and helium leak detection. Following successful implementation and positive results from initial tests conducted over several years of service, the client was impressed with the professional approach and performance reliability of the HVTS® solution. Based on this proven track record, they expanded the application to additional amine process vessels across their facility.

HVTS® Technology for In-Situ Corrosion Mitigation

High Velocity Thermal Spray (HVTS) technology is engineered to deliver robust CO₂ corrosion protection across varied CCS applications:

- Engineered NiCrMo alloys specifically designed for aggressive process environments

- Dense, impermeable protective barrier against corrosive agents

- High durability ensuring vessel integrity throughout operational lifespan

- Versatility in application to complex geometries, including internal piping and weld seams

Key Advantages of Advanced Cladding Systems

- Superior resistance to wet CO₂ corrosion and other acidic environments

- Protection against high-temperature sulfidation and impurities in CO₂ streams

- Rapid on-site application during planned maintenance turnarounds

- 3× faster application than welding

- Compatible with existing weld overlays

- No welding-related distortion

- Proven performance in the world’s largest energy facilities for over 30 years

Best Practices for CO₂ Corrosion Prevention

Proactive Approach to Corrosion Management

Implementing comprehensive prevention strategies requires:

- Expert material selection based on specific process conditions

- Surface protection technologies appropriate to the corrosion mechanism

- Regular monitoring and inspection protocols

- Rapid response capabilities for emergency situations

Quantifiable Performance Improvements

Implementation of comprehensive corrosion management systems yields the following measurable outcomes:

- Equipment service life extension by 15+ years

- Maintenance cost reduction of 30-50% over equipment lifecycle

- Downtime reduction demonstrated across multiple case studies

- Integrity management compliance with API 571/584 standards

- Mitigation of unplanned failure modes

Technical Consultation

CCS facilities must address carbon capture and storage corrosion with purpose-built mitigation strategies strategies specific to CO₂-rich process environments. HVTS® technology offers a field-proven solution for extending equipment life and maintaining operational efficiency.

Technical specifications and case studies are available upon request to assist engineering teams in evaluating solutions for specific process vessels and equipment susceptible to CO₂ corrosion mechanisms.