Rapid Maintenance during Crude Heater Operation

Crude Heater in a US Refinery

Having recently celebrated its 75th year of operations in 2018, this US Refinery located in Montana has the ability to process 205,000 bpd of crude oil from Canada.

Pressing Problem

This refinery has previously experienced a major upset a year prior where they had to stabilize multiple tubes in the emergency shutdown. Electrical outage caused the tube supports to be unstable.

When the new tube support issue was identified, they wanted the problem corrected as soon as possible as an “insurance policy” to last until the next scheduled shutdown.

PROBLEM

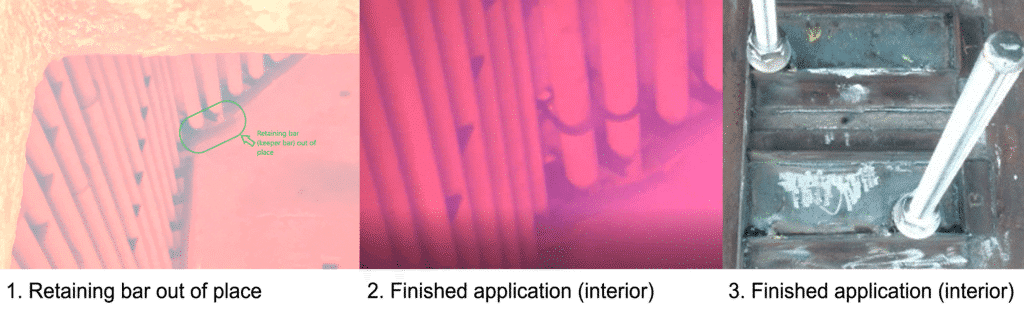

Two tubes in a crude heater have partially lost their tube support. The retaining bar fell out of place.

SOLUTION

In order to prevent a potential unplanned shutdown in the future, IGS Hot-tek delivered a turnkey solution, installing tube stabilizers while the heater continued normal operation.

Timely Solution

IGS Hot-tek supplied the tube stabilizers (manufactured out of 310 SS), welders and consumables required for this project. Proprietary J-Hooks were applied as part of this turnkey service, completed in two shifts.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.