PWR Corrosion Control in the Nuclear Industry

Enhancing Nuclear Plant Efficiency and Longevity Through HVTS Cladding

As Pressurized Water Reactors (PWRs) in the nuclear industry age beyond 40 years, asset reliability and maintenance costs have become a growing concern. Corrosion-related damage – particularly Flow Accelerated Corrosion (FAC), erosion-corrosion, and crevice corrosion – can threaten uptime, safety, and lifecycle economics of secondary systems.

IGS offers a transformative approach: High Velocity Thermal Spray (HVTS) cladding engineered to protect critical components like feedwater heaters, steam generators, and condensers. Unlike traditional methods such as weld overlay or full component replacement, HVTS delivers fast, field-deployable, and heat-free cladding solutions that align with ALARA principles and minimize exposure.

In addition to HVTS cladding for corrosion mitigation, IGS also provides specialized surface solutions like Cetek® 800, a high-emissivity coating engineered for thermal performance and inspection clarity in advanced reactor systems.

Understanding Corrosion Risks in PWR Operations

Pressurized Water Reactors (PWRs) operate under high pressure (around 2248 psi/ 155 bar ) to prevent water from boiling at high temperatures, allowing the coolant to enter the reactor core at roughly 527°F/ 275°C and exit at 599°F/ 315°C. In this system, water serves a dual role as both coolant, absorbing heat from the nuclear reaction, and moderator, slowing neutrons to maintain the chain reaction. This heated water then transfers its energy to a secondary circuit, producing steam to drive turbines and generate electricity.

Outlined below are some common corrosion mechanisms observed in PWRs.

Common Corrosion Mechanisms in Secondary Systems

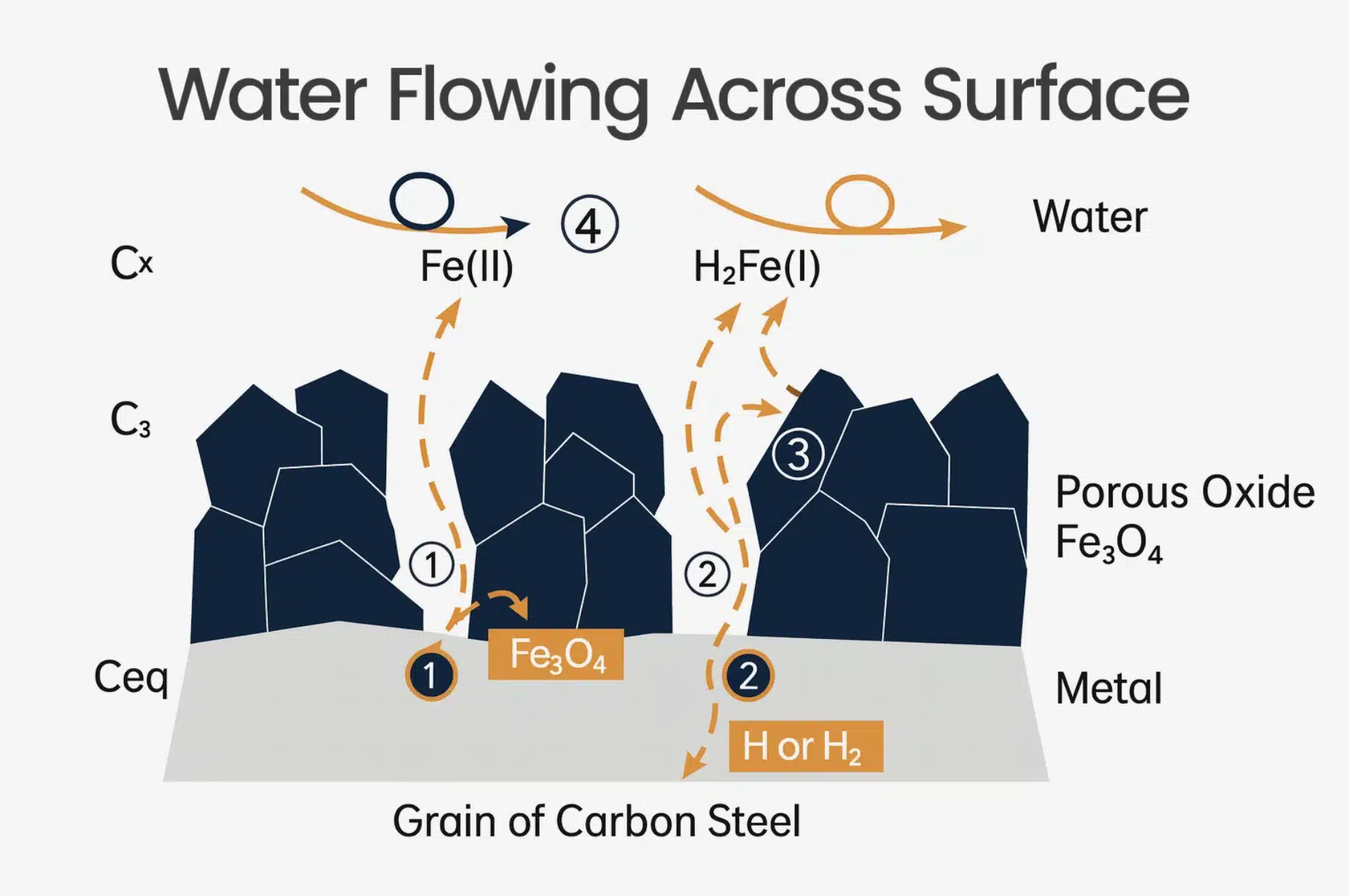

1. Flow Accelerated Corrosion (FAC)

This is where the protective oxide layer on carbon steel piping is dissolved and removed by flowing water or wet steam. Common in both singleand two-phase flow conditions, FAC is accelerated by high flow rates, turbulent hydrodynamics, water chemistry (pH, oxygen content), and temperatures typically between 200-450°F /~93–232°C.

PWRs are particularly vulnerable due to their high-energy feedwater and steam piping systems, where FAC can cause sudden ruptures, posing risks to plant operations and safety systems. Effective FAC management is essential to detect, monitor, and mitigate this risk, especially in areas with complex pipe geometry and susceptible material compositions.

2. Erosion Corrosion

This is a degradation mechanism driven by the combined effects of chemical corrosion and mechanical wear. It primarily affects high-pressure turbine exhaust piping, turbine casings, extraction steam lines, and feedwater piping. Erosion-corrosion occurs when flowing water or steam dissolves protective oxide layers (FAC), while mechanical erosion from droplets or particles further disrupts these layers. Carbon steel alloys with higher chromium or molybdenum content offer better resistance. The consequences of not upgrading the base metallurgy includes pipe wall thinning, leaks, unplanned outages, and potential safety risks. This makes erosion-corrosion a critical concern for plant reliability and integrity.

3. Primary Water Stress Corrosion Cracking (PWSCC)

A critical degradation mechanism in PWRs, it primarily affects nickelbased alloys such as Alloy 600. It occurs when these susceptible materials are exposed to high tensile stresses in the aggressive, high-temperature, high-pressure primary water environment of a PWR. Commonly affected components include reactor vessel head penetration nozzles, dissimilar metal welds, and steam generator tubes.

4. Crevice Corrosion

Crevice corrosion is one of the most serious forms of localized attack in nuclear power plants, particularly within steam generator (SG) tubes in PWRs. It occurs in confined spaces, like tube support crevices or under sludge piles, where local chemical environments become aggressive due to restricted fluid flow and temperature gradients.

Factors like high concentrations of chlorides, sulfates, and oxidizing species, especially under All-Volatile Treatment (AVT) chemistry, can exacerbate the issue. While materials like stainless steel tube support plates and Alloy 690 have reduced crevice corrosion, it remains a key threat to component integrity, often leading to costly SG tube replacements.

5. Intergranular Attack (IGA) and Stress Corrosion Cracking (IGSCC)

IGA and IGSCC are corrosion mechanisms that affect the grain boundaries of metal alloys, particularly Alloy 600 and, more recently, Alloy 800. In SG tubes, IGA typically initiates in hot-leg crevices or sludge pile areas where alternate wetting and drying promote aggressive chemistries. Over time, IGA transitions into IGSCC, with cracks propagating through the tube wall, leading to primary-tosecondary leaks of radioactive material. Despite Alloy 800’s improved resistance over Alloy 600, IGSCC has still been observed in creviced regions, especially under cold-worked conditions and in acid-sulfate environments, highlighting the continued importance of mitigation methods.

HVTS: High-Performance Cladding Without the Heat

HVTS is an advanced thermal spray technology that accelerates metallic particles with significantly higher velocities than conventional thermal spray methods. Through its patented nozzle design, the process generates supersonic gas velocities, which in turn accelerate cladding particles to high impact speeds that form dense, engineered superalloy layers. This results in denser, more adherent claddings with superior mechanical and corrosion resistance properties.

Unlike traditional methods, HVTS involves no heat input – eliminating distortion, HAZ, and the need for post-weld heat treatment. It delivers shop-quality cladding performance directly in the field, ideal for complex geometries and time-sensitive maintenance windows.

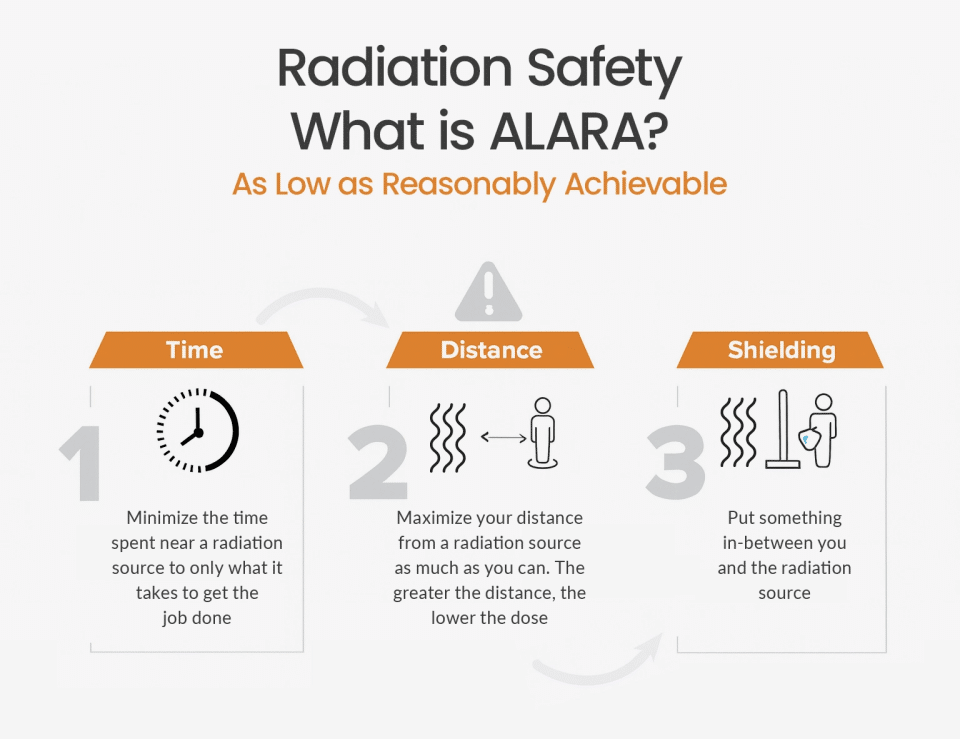

Supporting ALARA Through Smarter Maintenance

By minimizing application time and eliminating hot work, HVTS naturally aligns with the ALARA (As Low As Reasonably Achievable) principle – helping reduce radiation exposure during maintenance in nuclear environments.

Reduce Outage Time and Improve Radiation Safety

HVTS cladding offers distinct advantages over conventional methods:

-

No post-weld heat treatment (PWHT) required

-

No heat-affected zones (HAZ) – preserving base metal integrity

-

40–60 ft²/hr spray rate per gun, enabling critical path time savings

-

Localized repairs possible with minimal downtime

-

Zero dilution into base material

Field-deployed HVTS applications eliminate the need for heavy equipment, welding, or vessel distortion – making it ideal for Class 2/3 and non-pressure boundary components.

Comparison Table of Corrosion Barrier Technologies (HVTS & WOL)

| Feature | High-Velocity Thermal Spray (HVTS) | Weld Overlay (WOL) |

|---|---|---|

| Corrosion Resistance | Yes | Yes |

| Erosion Resistance | Yes | Medium (depending on alloy) |

| Typical Alloys Utilized | Modified 625, C-276, Monel | 316, 625, 622, 52, Monel, Hastelloy |

| Bond Type | Micro-mechanical interlocking (MMI) | Metallurgical/chemical |

| Typical Thickness | ~20 mils | 5–7 mm (≈200–275 mils) |

| PWHT Requirement | No | Sometimes required |

| Dilution into Base Metal | No | Yes |

| Heat-Affected Zone (HAZ) | None | Yes |

| Stress/Distortion | None | Possible on thin components |

| Application Speed | Medium-Fast | Slow |

| Repairability | Localized, simple | Complex (grind and reweld) |

| Thermal Resistance | >932°F / >500°C | >932°F / >500°C |

| Curing Requirements | None | None |

Trusted by Global Operators to Extend Asset Life and Minimize Cost

IGS HVTS cladding has been proven under harsh nuclear conditions, including:

-

Operating pressures up to 2,500 psi (17.2 MPa)

-

Temperatures exceeding 572°F (300°C)

-

Chemically aggressive service environments with chloride excursions and oxygen ingress

Key test results include:

-

No pitting or crevice formation after 10,000-hour immersion

-

Minimal mass loss in ASTM G48 and G28 corrosion tests

-

Proven protection for 15+ years in multi-industry deployments

“We’re delivering proven, field-qualified cladding solutions that align with ALARA principles while significantly reducing outage durations and lifecycle maintenance costs.”

Keith Reeser, Senior Director of Business Development at IGS

I’m here to help

Keith Reeser

IGS Subject Matter Expert

HVTS for Maximum Uptime and Predictable Maintenance

HVTS represents a technically robust, cost-effective, and safetyaligned enhancement to traditional erosion-corrosion remediation in nuclear secondary systems. Its low heat input, faster application, superior bond integrity, and extended performance life provide key benefits for outage planning, dose control, lifecycle cost reduction, and asset longevity.

HVTS is not a universal solution for all corrosion scenarios, but it does excel where time efficiency, metallurgical integrity, and lifecycle value are aligned priorities, especially in class 2/3 and non-pressure-boundary components.

HVTS Benefits Summary:

- Outage Efficiency: typically 2-3X faster than weld overlay for similar coverage

- Radiation Safety: reduced cumulative worker exposure due to faster application

- Metallurgical Merit: no HAZ, strong bond, minimal dilution, high porosity control

- Durable Protection: proven 15+ years of corrosion/erosion resistance

- Cost Savings: Lower labor and equipment costs, predictable maintenance budgets

Reactor Emissivity Solutions with Cetek® 800

While HVTS protects against corrosion and erosion, Cetek® 800 is IGS’s reactor-grade high-emissivity coating for components where radiation heat transfer, inspection clarity, and thermal margin matter.

Proven across industrial and aerospace applications, Cetek® 800 is designed, manufactured, and applied exclusively by IGS to deliver durable, high-E performance under nuclear QA standards.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.