Troubleshooting Fired Heater Start-Up Issues with IGS Hot-tek Services

Start-up, even after a planned shutdown is one of the most vulnerable phases for fired heaters. Even with strict adherence to ramp-up procedures, mechanical failures, fouling, and uneven thermal expansion can impact efficiency, emissions compliance, and asset integrity.

IGS Hot-tek™ services offer live, in-operation maintenance to address these start-up challenges. This blog explores common start-up issues and how IGS solutions such as Hot Refractory Repair, Hot Convection Cleaning, and Hot Tube Stabilization help plants maintain performance and avoid unplanned shutdowns.

Common Start-Up Issues in Fired Heaters

Refractory Failures Due to Expansion and Thermal Shock

Fired heater linings expand rapidly during start-up. If anchors are corroded or weakened, refractory bricks or castables may detach, creating insulation gaps and localized overheating.

The Hot Refractory Repair service allows in-situ repair of refractory while the unit remains online, avoiding shutdowns and restoring thermal integrity.

Case Study Highlight – Emergency Hot Spot Repair Prevents $15M Shutdown

A major refinery faced a critical failure in the roof of its CCR fired heater, where multiple anchor points failed and caused ceramic fiber refractory to collapse. This exposed the steel shell to flue gases, risking structural failure and an emergency shutdown.

IGS responded immediately, deploying Hot Refractory Repair (HRR) services while the unit remained in full operation. The initial scope of three hot spots was expanded once the refinery team saw the safe execution and effectiveness of the work.

In total, IGS repaired over 200 ft² of casing, replaced significant sections of refractory, and restored mechanical integrity across multiple furnaces, all without any production loss. With temperatures exceeding 1300°F (700°C) in some zones, the project was completed safely and on schedule.

- $15 million in avoided downtime

- Repairs completed with zero safety incidents

- Long-term integrity restored, with future inspection planned during the next turnaround

Debris and Fouling in Convection Sections

Dust and debris from maintenance activities can migrate during start-up and settle in convection section tubes and SCR catalyst surfaces, degrading thermal performance and emissions control.

Hot Convection Cleaning removes fouling online, restoring performance without delaying operations.

Case Study – Online Convection Cleaning

At a major refinery, stack temperatures exceeded design limits by 54%. IGS conducted online defouling of 40% of the convection section. The outcome:

- Stack temperature reduced by 66°F / 37°C

- Furnace efficiency improved by 1.75%

- Recovered 2.46 MMBtu/hr in duty without a shutdown

In parallel, Hot Vacuuming Service (HVS) restores SCR catalyst function by removing upstream fouling while maintaining full environmental compliance.

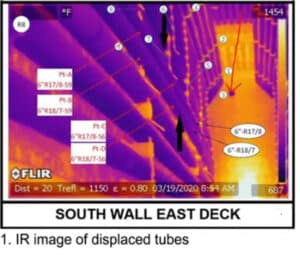

Process Tube Displacement and Uneven Heating

In heaters operating up to 1600°F (871°C), process tubes expand unevenly. This can dislodge tubes from their supports or damage hangers, creating safety and reliability concerns.

Hot Tube Stabilization provides engineered, high-temperature supports that can be installed during normal operation.

At a U.S. refinery, IGS installed stabilizers in a vacuum heater where retaining bars had failed. The work was completed in two shifts without interrupting operations, preventing an unplanned shutdown and eliminating the need for continuous monitoring.

Where phase separation or revamp-related changes lead to localized overheating, Tube Shielding Service (TSS) can be applied during short outages or online, depending on access and process conditions.

Locating the Problem With Hot Inspection in Live Equipment

When issues like shell hot spots or dropped refractory appear, internal damage can be difficult to pinpoint. The Hot Inspection Service uses the patented Lancescope™ to perform internal inspections up to 3000°F (1650°C) while the unit is running.

This diagnostic capability allows precise targeting of services like hot refractory repair or tube stabilisation and avoids unnecessary shutdowns or guesswork.

A Strategic Addition to Reliability Planning

Integrating Hot-tek services into your maintenance strategy offers several advantages:

- Extend run lengths between turnarounds

- Reduce unplanned shutdown risks

- Maintain emissions compliance and thermal efficiency

By using live maintenance solutions as part of a broader reliability framework, operators gain flexibility, reduce downtime exposure, and improve the long-term integrity of their fired heaters.

Delivered with Safety and Precision

All Hot-tek services are performed by certified field teams under strict safety protocols. Services are engineered with detailed risk assessments and executed under site-specific permit systems.

Field teams are trained in high-temperature welding, refractory work, and thermal imaging, supported by IGS’s ISO-certified quality and safety management systems.

Summary

Start-up risk is inevitable, but it doesn’t have to lead to unplanned shutdowns or lost production. IGS Hot-tek services provide reliable, engineered solutions that address start-up challenges while your heater stays online.

Ready to Improve Your Start-Up Performance?

Let’s talk about your next start-up. Whether you’re planning a turnaround or facing performance limitations mid-run, IGS can help.

IGS has global availability across five continents. See where we operate.