Stripper Tower H2S & HCl Corrosion Protection at Gulf Coast Refinery

Plant Profile

- One of the largest refineries in the United States

- Located in Houston, Texas

- Processing capacity: 585,000 barrels per day

- Strong emphasis onmechanical integrity and preventative maintenance

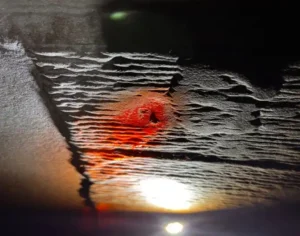

H2S & HCl Corrosion

The refinery was experiencing significant corrosion issues in two critical stripper towers and later discovered similar problems in a nearby debutanizer.

The primary damage mechanisms were hydrogen sulfide (H2S) and hydrochloric acid (HCl) corrosion.

These corrosion issues threatened operational efficiency and posed potential safety and compliance risks.

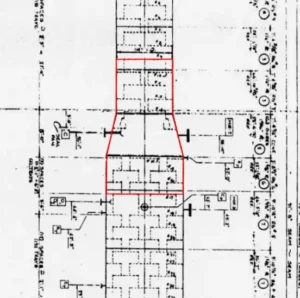

Initial Scope

- Two stripper towers requiring corrosion protection

- Combined surface area of approximately 2,400 ft²

- Existing condition included:

- Previous weld buildup in some areas

- Heavy erosion and scale

- Weld splatter

- Various pit defects

Solution Development

Upgrading the material with HVTS® will freeze the condition preventing further thickness loss and avoiding the need for further build-up in the future. The IGS team worked closely with the refinery to develop a comprehensive solution:

Information Gathering

- Collected detailed process media chemical composition

- Analyzed maximum operating temperatures

- Reviewed previous inspection reports

- Shared data with metallurgy team in Richmond, Virginia, for analysis

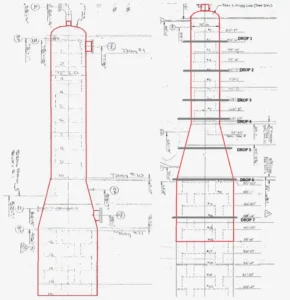

Expanded Scope

- During the planned maintenance, corrosion was discovered in a nearby debutanizer

- Added this 860 ft² vessel to the project scope

- Created a series workflow to maximize efficiency with one mobilization

Implementation

- Applied HVTS® cladding system

- Worked in series across all three vessels

- Operated on a 24-hour schedule with two shifts per day

Timeline and Efficiency

- Original timeline: 12-day critical path duration for both stripper towers

- Additional 5 days for the debutanizer work

- Project executed during peak season (Fall 2023)

- 50% faster and more economical than traditional weld overlay alternatives

- The metallurgy of internals upgraded with no need for replacement

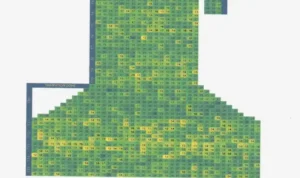

Quality Assurance

- Conducted thickness measurements at approximately one-foot intervals

- Performed salt reading tests

- Created detailed surface thickness maps

- Ensured homogeneous and uniform application across all vessels

Results

- Successfully maintained planned turnaround schedule despite expanded scope

- Provided stress-free maintenance solution

- Enhanced long-term equipment reliability

- Eliminated the risk of pressure boundary failure

- Eliminated the risk of distortion

Conclusion

This case study demonstrates IGS’ ability to execute both planned maintenance and handle emergent discovery work efficiently. By implementing HVTS® corrosion protection solution, IGS provided the refinery with a faster, more economical alternative to traditional weld overlay while maintaining exceptional quality standards.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.