Hot Refractory Repair Saves Refinery $2.4 Million and Prevents Downtime

Problem

A major refinery faced a significant refractory failure in one of its heaters.

Solution

The issue was resolved without downtime by using IGS’s Hot-tek Hot Refractory Repair service, saving the refinery $2.4million.

Figure 1. Internal partial view of damaged area

Figure 2. External view roughly mapped

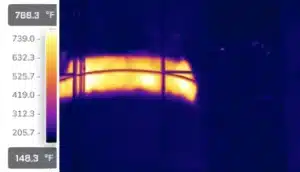

Figure 3. External infrared image

Background

In July 2024, a refinery processing 173,000 barrels of crude oil daily encountered a critical problem with one of its heaters. The facility, which produces essential fuels such as gasoline and diesel, as well as petrochemical feedstocks, faced the risk of a costly shutdown due to a refractory failure.

The refinery identified a refractory failure affecting an area of approximately 20’6” wide by 5’ high in one of its heaters.

If this problem had not been addressed promptly, the refinery would have needed to shut down the heater for conventional repair, leading to six days of lost production and an estimated repair cost of $2.4 million. Given that the refinery had recently experienced an unplanned outage, they were highly motivated to find an alternative solution.

Avoiding A Disruptive Shutdown

To avoid another costly and disruptive shutdown, the refinery opted for IGS’s Hot-tek HRR services. This solution allowed the repair to be completed in just 9 days, without interrupting production. The repair effectively reduced the external shell temperature from 830°F to 130°F, eliminated the need for cooling steam, and minimized the monitoring required for the unit.

The use of IGS’s Hot-tek Hot Refractory Repair service saved the refinery approximately $2.4 million by avoiding downtime and maintaining continuous production. The return on investment was immediate, with significant improvements in operational efficiency and reduced maintenance needs.

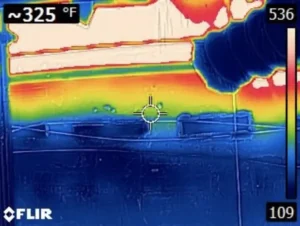

Figure 4. Partial repair IR image: Blue area at the bottom shows the new refractory

Figure 5. Final IR: Area within the yellow rectangle is the repair zone

IGS Surface Solutions Package

IGS offers a range of online fired heater services, including:

With decades of experience and a commitment to excellence, IGS has repaired over 50 fired heater hot spots in the last 10 years without any impact on production, solidifying its position as a global leader in fired heater maintenance.

I’m here to help

Larry Emch

IGS Subject Matter Expert

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.