Combating Flow Accelerated Corrosion in Power Plants with IGS HVTS Technology

Introduction

Flow-accelerated corrosion (FAC) is critical in nuclear power plants, particularly within Moisture Separator Reheater (MSR) components. MSR internals, including moisture separator drains and reheater tubes, are constantly exposed to high-velocity, high-temperature steam laden with moisture and aggressive impurities. This environment creates a perfect storm for FAC, leading to rapid material degradation, compromised component integrity, and potential safety hazards.

This blog explores the growing application of IGS High Velocity Thermal Spray (HVTS) technology as a powerful solution for mitigating FAC in moisture separators. We will delve into the technical aspects of HVTS and its distinct advantages in addressing this prevalent nuclear power industry challenge.

Understanding Flow-Accelerated Corrosion (FAC)

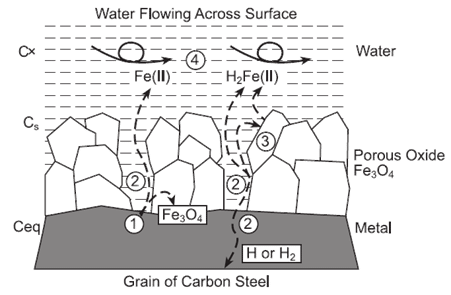

FAC is a complex phenomenon driven by the synergistic effects of erosion and corrosion. High-velocity moisture droplets laden with dissolved impurities impinge on moisture separator and reheater internals, causing:

- Erosion: The continuous bombardment removes protective oxide layers and exposes fresh metal surfaces to further corrosion.

- Corrosion: The exposed metal reacts with the corrosive species in the steam, leading to material loss and potential component failure.

These combined mechanisms can significantly reduce the lifespan of moisture separator reheater components, necessitating replacements and potentially causing safety concerns. Traditional mitigation strategies, such as material selection and operational adjustments, often have limitations.

The IGS HVTS Advantage

IGS HVTS is a well-established surface modification technology with a proven track record in combating FAC within various industries, including nuclear power. It involves depositing a dense, metallurgically bonded metallic coating onto the substrate material at high velocity. This coating offers several advantages for MSR applications:

- Enhanced Erosion Resistance: The HVTS coating exhibits exceptional hardness and improved erosion resistance compared to the base metal. This significantly reduces the impact of high-velocity moisture droplets, minimizing erosion and subsequent corrosion.

- Superior Corrosion Protection: The coating material can be specifically chosen to offer superior resistance to the specific corrosive species present in the MSR environment. This significantly retards corrosion processes and protects the underlying substrate.

- Strong Metallurgical Bond: The HVTS process creates a strong metallurgical bond between the coating and the substrate, ensuring excellent adhesion and long-term performance in the harsh moisture separator reheater environment.

Benefits of IGS HVTS for Mitigating FAC in MSRs

- Extended MSR Lifespan: By mitigating FAC, HVTS coatings can significantly extend the service life of MSR components, reducing the frequency of costly replacements and outages.

- Enhanced Plant Safety and Reliability: Improved component integrity due to HVTS coatings translates to reduced risk of failures and improved plant safety and reliability.

- Reduced Maintenance Costs: By minimizing FAC-related issues, HVTS can significantly reduce maintenance costs associated with MSR repairs and replacements.

Conclusion

IGS HVTS technology presents a compelling solution for combating FAC in nuclear power plant MSRs. Its ability to enhance erosion and corrosion resistance, coupled with its strong metallurgical bond, makes it a valuable tool for extending MSR lifespan, improving plant safety and reliability, and reducing overall maintenance costs.

Disclaimer: The information provided in this article is for general informational purposes only and does not constitute engineering advice. Always consult with qualified nuclear engineering professionals for specific applications in nuclear power plants.

Speak to a flow-accelerated corrosion advisor today.

More corrosion and erosion management articles from Integrated Global Services:

CO₂ Corrosion Prevention and Control in Oil and Gas Production

How to Prevent Microbially Influenced Corrosion (MIC) with On-Site Alloy Upgrade

Why is High Emissivity Coating Durability Important in Fired Heaters?

Strategies for Preventing Internal Pipeline Corrosion in the Energy Industry

Flue Gas Dew Point Corrosion Mitigation: Alloy Upgrading Techniques

Mitigating Metal Dusting Corrosion in Ammonia and Methanol Reformers

Why an Alloy Upgrade is the Best Solution to Crude Unit Overhead Corrosion Control

Protecting Hydropower Turbines from Corrosion with HVTS Coatings

Protecting Offshore Wind Turbines – Splash Zone Corrosion

The Critical Role of High Emissivity Coatings in Space Exploration

Organic Coatings in Pressure Vessels: Internal Coating Failure Analysis

How to Stop Corrosion on Your Refinery Distillation Column

Causes of Boiler Corrosion and Benefits of Boiler Tube Coating

5 Common Causes of Refractory Failure and How to Fix Them

Boiler Tube Leaks Prevented with Proactive Maintenance

Understanding Oil & Gas CO2 and NOx Emissions, and the Science Behind Reducing Them

A Guide to Amine Stress Corrosion Cracking in Oil & Gas Processing