HVTS Cladding- Solution to Tackle Fireside Corrosion and ensure Long-Term Reliability

Reliability Study

In the mid 2000s, a US power utility owner and a research institute performed a long-term study to determine if thermal spray technology would protect the sidewall tubes (adjacent to burner levels) from thinning caused by reduced sulfidizing atmospheres. A test panel with thermal spray products from IGS and another thermal spray provider were installed. After a 5-year run, the IGS HVTS alloy cladding had no sign of deterioration. Other products experienced cracking and cladding delamination. The important key point to note is the IGS alloy cladding protected the underlying tubing material, resulting in zero loss of wall thickness on the outer surface.

PROBLEM

The boiler was experiencing tube wall thickness wastage caused by operating the boiler in a reducing atmosphere (low NOₓ burners)which results in sulfidation corrosion. This boiler is the newest of the 1300 mw units but experienced very similar corrosion problems to others in use across the industry. Typical of boilers retrofitted with low NOₓ burners, areas of concern are: Sidewalls adjacent to burner elevations, front and rear walls in between burners and coutant slope, convection pass floor wastage caused by coal ash corrosion, upper furnace corrosion assisted thermal fatigue (CATF), and economizer wastage caused by fly ash erosion.

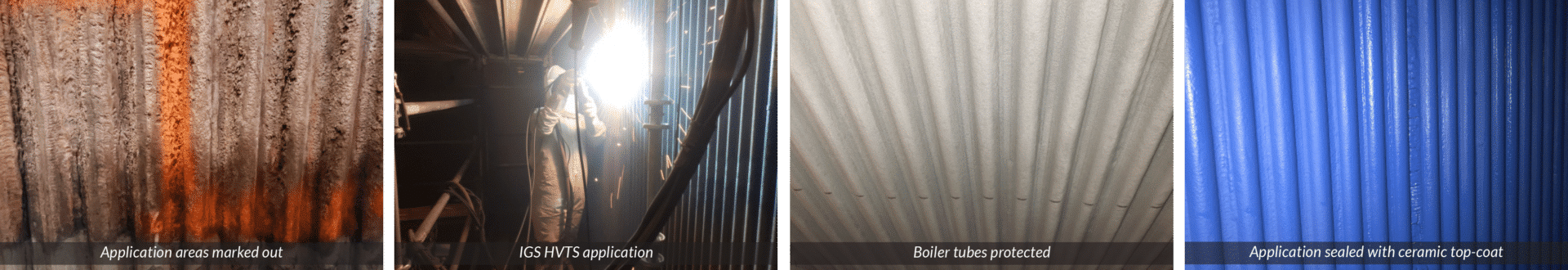

SOLUTION

During the Fall of 2019, the plant was in a major planned outage. A full furnace scaffold was installed for boiler maintenance and a tube assessment was performed. During the inspection, new wastage was discovered on the upper front wall just below the wingwalls, near the right sidewall. As a result of the previous testing of IGS HVTS in the boiler, and IGS’s status as a long-term, proven vendor, IGS was contracted to protect the damaged tubes on a very short notice.

The IGS value is more than just protecting boiler tubes from wastage. IGS HVTS Cladding service utilizes 5450 alloy cladding which is a permanent solution that is rapidly installed and improves reliability. Clients who are proactive in their maintenance strategy can realize significant capital savings by utilizing the IGS solution and prevent not only forced outages but eliminate future tube panel replacements.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.