Lessons Learned from Ensuring Circulating Fluidized Bed (CFB) Boiler Reliability

Interview with the Boiler Engineering and Maintenance Specialist

We are interviewing Joel Taylor, Boiler Engineering and Maintenance Specialist. Joel has ensured reliable operation of 7 Circulating Fluidized Bed Boilers between 4 Plants across his 15 Years of CFB Experience. Joel’s recent experience comes from 2X Foster Wheeler CFB Boilers that were burning Lignite Coal. Interviewing Joel is Ed Griffith, IGS CFB Boiler (SMARTGard®) Thermal Spray Expert, Integrated Global Services.

Ed:

Why did you initially decide to use thermal spray as part of your erosion mitigation and reliability strategy?

Joel:

One of the reasons is you need to consider what’s going on, what the erosion pattern is, or even the corrosion pattern. If it’s pure erosion, then you need to create a surface that is extremely smooth and that easily transitions from bare tube over into the thermal spray surface. If you use weld overlay, it’s going to be really bumpy, there’s a large step change from bare tube to welded overlay or hard facing. Whereas, thermal spray offers a very smooth transition. And when I’m saying smooth, I’m talking down to thousandths of an inch, whereas the welding is much more pronounced.

Ed:

Weld overlay, aka hard facing, is often used in erosion or wear situations. Have you considered using it in your boilers?

Joel:

We did not consider hard facing. The units that I’ve worked on had high-ash coals and extremely abrasive ash. Hard surfacing creates irregular patterns, as far as smoothness if you will, and then that sets up little locations for eddys. There were areas in some of the boilers that I worked on that were hard faced, and we would go in every year and remove that hard facing based off of priority, because it was starting to gouge into the tubes.

I did work with a small boiler where the hard facing was used in the lower combustor and it worked for many years until they made a fuel change. And then that hard facing no longer would hold up to their new ash that was being recirculated inside the CFB and they eventually had to go to a High Velocity Thermal Spray (HVTS) application.

Ed:

With regards to various locations in the boiler, various erosion rates, what is the range of problems that you solved with HVTS?

Joel:

When you do an inspection, you need to break your boiler into smaller pieces. For example, the lower combustor, the front wall, the roof tubes and then the left- and right-side walls, and then the rear wall upper combustor (as high erosion zones).

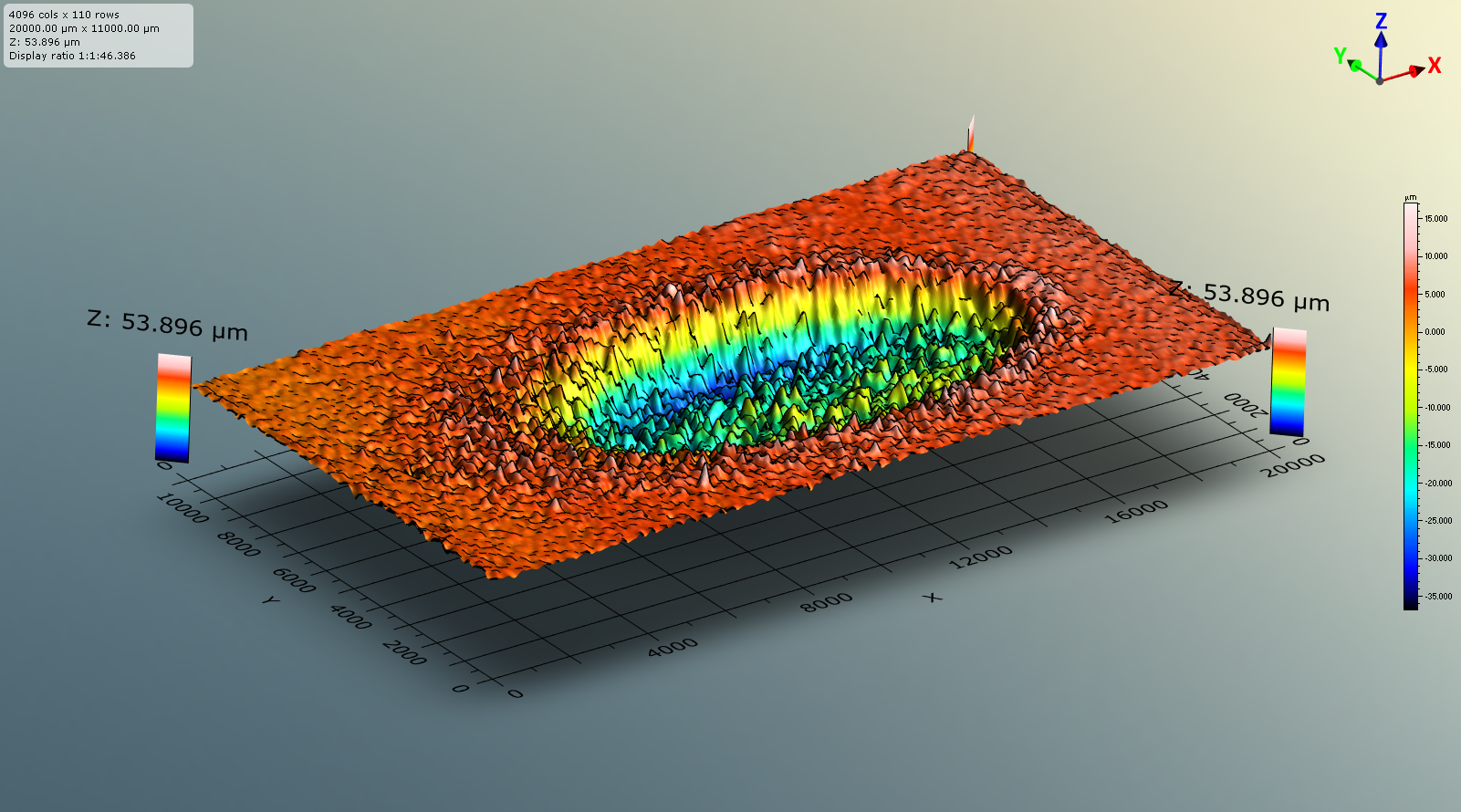

From an erosion standpoint, our biggest erosion area was actually in the lower combustor at the corners. The specification there would vary. Then as we crawled higher up from the refractory interface, that erosion wall loss per year would decrease, except for when you get up to the cyclone outlets at the rear upper wall. On the left- or right-side walls, you get preferential erosion on one side of the tube. One side, you’re losing .020” (.5mm) a year, the next side you’re not losing anything. IGS adjusted their specification accordingly, to the wear characteristics of our boiler.

The refractory interface was ultra-challenging because you have protruding tubes and you get ash falling down to a refractory interface. There’s a change in direction of the ash, which is a problem by the tube/refractory interface, and we were spraying that up to higher thicknesses each year because of the massive amount of erosion.

You really need to understand what’s going in different sections of the boiler and then work with the thermal spray team to tailor the application for that.

Ed:

Do you believe there are effective alternatives to the use of thermal spray for erosion-corrosion mitigation in CFB boilers?

Joel:

There are some alternatives, but it’s strictly dependent on the process. If you have a higher erosion process, thermal spray is the way to go, compared to installing a welded cladding or even installing refractory over higher erosion areas. If you implement those other alternatives to thermal spray, you just moved your problem to another location, you end up with refractory interface issues. One issue with the welded overlay is, you can’t measure the thickness. You can obviously see the erosion process and then you have to send welders back in to refurbish that weld. But again, if you’re in a high erosion process, that’s not the correct prescription for that issue due to the gouging that occurs with welding in CFB boilers.

And then just the welding process itself is extremely time consuming, and then you also end up with potential bowing of your tubes due to the high heat input into one side of the tube. You can also end up with a burn-through. I’ve had this issue before where the welders weren’t necessarily doing weld overlay, but they were doing a tube repair and then they burned through the tube and didn’t tell anyone, causing a later tube failure.

The genius thing about the thermal spray is you can install it over extremely thin tubes. We installed it over a tube that was about 50 thousandths of an inch (1.27mm) thick. And we ran for an entire year like that and then went back in for the next inspection.

The tube was still performing as desired. The thermal spray protected the thin wall (arrested the tube thickness in its current condition) and we were able to replace the tube at the next planned outage rather than during the current outage or a forced outage that it would have caused if unprotected. You really need to understand the process of your wall thickness loss to make the correct call. I prefer the thermal spray. I can measure it. I can see it. I’ve seen it work rather than a welded overlay for example.

Ed:

Having used thermal spray for 15 years, what do you think of the total cost of ownership relative to other strategies, such as doing repetitive replacement, weld build up or other strategies?

Joel:

One of the things we experienced over a seven-year period is that we had a very large mechanical repair process (during each outage) for about three years. That included replacing boiler tubes, restoring wall loss, and repairing erosion areas. Extremely labor intensive. Typically, we’re looking at 20 workers per shift and the process took about 8 days (i.e., 16 shifts) with 20 men per shift. And we were doing thermal spray cladding in addition to that.

As we reduced or permanently fixed some of our mechanical problems, our mechanical repair process started shrinking and we were actually able to get that down to a single shift using four people, and only one of those people was a welder, the other three were trained on how to grind to the CFB required standard. And then our thermal cladding process, it didn’t necessarily grow, but we were able to predict where we were going to install it and where we were going to have to refurbish the material, just based off our inspections from year to year.

We went from a varied scope and high man hours to lower man hours and a known scope, which is great for planning for an outage, especially for the budget. Because of our process and work with IGS we didn’t need to replace pressure parts. When you start doing pressure part replacement in circulating fluidized bed boilers, you run into all kinds of issues because you have to do tube alignment. There are certain procedures that should be used. If the tube alignment is not done correctly, you’re going to end up with erosion or gouging issues for the rest of the life of those pressure parts, that’s extremely difficult to fix.

So, it was a lot of fun to see that mechanical repair process shrink down and we were getting to the point where the boilers were no longer the main driver for outages and that is really attributed to the High Velocity Thermal Spray (HVTS) cladding that was installed.

Ed:

Did you have to replace the HVTS protective thermal spray outage to outage?

Joel:

The only time we ever completely removed the material was so that we can make a permanent mechanical repair to the boiler to do fabrication like a design change or installation on the tube itself. For example, an improperly welded membrane, an old weld overlay that we installed thermal cladding over just as a stop gap for a year, but we never completely removed the material to repair the material. We only had to replace thermal spray, when removal was required in a localized area, for a mechanical tube repair.

If you’ve got areas that have crazy high erosion, you’re going to have to refurbish the material. It doesn’t mean you have to do it every year. The need to refurbish would be based off of criteria and managing the remaining longevity of the existing material. But those refurbishments are going to be required eventually and this is where the quality comes into play. If you understand your process, understand your erosion, wall loss per year, and then you start tracking your thermal spray wall loss or thickness loss per year, you can really start controlling the amount of refurbishment per year. And we’re talking 50,000 to 100,000 square foot of application done inside of a boiler and the amount of refurbishment is a very small percentage of that.

Ed:

What would your view be on using iron-based coatings, which aren’t measurable with the traditional method of magnetic liftoff techniques?

Joel:

We never even considered iron-based unless it was strictly just completely temporary, and we plan to remove it next year. The measurability is so important, especially in the erosion area. The cladding in the erosion areas needs to be measurable so that you can inspect it from year to year.

Ed:

Do you think it is beneficial for your thermal spray vendor to have a good understanding of their materials’ capability?

Joel:

Definitely. We had some areas that we needed to have covered, they were in a corrosion environment. We had very little money, it was an unplanned scope, discovery work. The IGS team recommended a product that was less expensive and could provide a temporary solution, with the condition that we would go back and eventually replace that material, because it would not last as long as the material that we were hoping to use. It did the exact job that we wanted it to do and it lasted a bit longer than we expected. And they eventually went back over, removed and installed a better material for the longevity of the plant.

Ed:

In 2017, your management team, insisted or encouraged you to trial a different thermal spray vendor to your usual contractor. Could you please describe your experience?

Joel:

This decision was made purely on budget and it didn’t include some of the intangibles, like the review of the history of the unit, having knowledgeable people that have worked on similar units at different facilities with different companies. And the biggest difference was really the quality control. As I mentioned before, we had a unique IGS HVTS specification. We had multiple specifications, so different areas got different thicknesses sprayed on based on the wear rate in each location. The other contractor did not have the capability or the knowledge to perform the appropriate quality control measures.

Two other individuals (plant end-user employees) and I had to perform that function ourselves. We found ourselves working extremely long days, crossing over multiple shifts. Then since they didn’t have a proper QA process for our application, the thermal spray time was increased (extending the outage schedule unexpectedly), mainly because they had to go back and make repairs that we identified, remove material and then reinstall it. Then we’d go back to perform quality control checks. It made life very miserable for us for that outage, even though on paper, we saved a few nickels, I believe that we got an inferior product by using a different vendor.

Ed:

How do different thermal spray vendors compare in your experience?

Joel:

The first is the materials. IGS helped us stop the corrosion completely, so that became a non-issue. Regarding the erosion process, we were able to gain control of the erosion component.

I’ve looked at a lot of other companies that do thermal spray. In one of the facilities I worked at, we installed a panel that had a different vendor’s shop-sprayed application on it, a month later we had a tube failure, not in that area, but when I went over to do the inspection, that cladding was entirely gone, 100%, you couldn’t even tell that it had been thermally sprayed at all. That material obviously did not work. It might be good for maybe a corrosion process or for preventing slag, but it did not work for erosion.

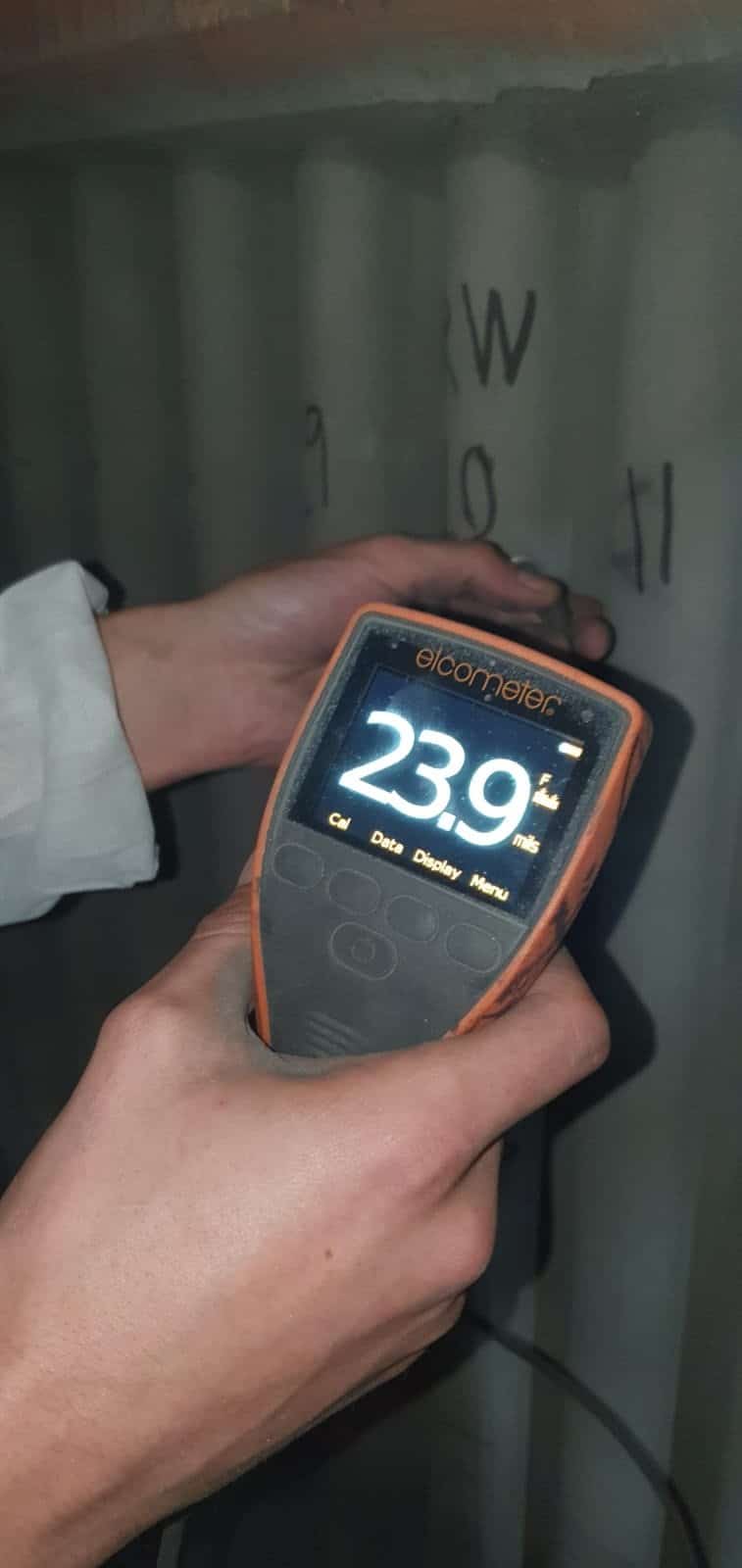

There also needs to be knowledge of where to put the material for the process that is damaging the tubes. The other is just the quality. There’s nothing worse in a plant than fighting with installing the cladding. Say, you ask for 20 mils back, you go in, you do your inspection, and it’s 5 mils. There’s nothing worse than that. And now you’re having to move resources back to an area to get it sprayed up to thickness and then what will usually happen is they’ll actually overspray it, so then it’ll be too thick and now you have to remove material, so you just end up chasing your tail a lot on the quality.

And then just the knowledge of the applicators. When they were installing the material, IGS could perform their own inspections and see the issues prior to my inspection and they can fix them on their own. If they have some little bumps or something like that, that’s unacceptable, they could fix those prior to my inspection. IGS saved me days of inspection, and plus I only have 2 eyes. But if I have 8 guys that are spraying, now I’ve got 16 trained eyes looking at the cladding and it just makes the overall quality of the product better.

Ed:

What do you think the key aspects to success are related to utilizing a thermal spray technology in CFBs? Is it material? Is it the actual application technology? Is it the people knowing where and when to use thermal spray?

Joel:

That’s a difficult question to answer. I’m going to say it’s all three. You know, if you have a good material that’s going to work, that’s fantastic. But, If you can’t get it on the wall correctly, it won’t work. And then you can have great people and then a poor material, then you still can’t be successful. You have to have all three to have a successful application, to have a successful project.

The people make the biggest difference. The installation of a good material is not automated. This work is repetitive. It’s a really poor environment that you’re working in – it’s hot, you’re going to be sweaty. It’s going to be loud. And it takes a special group of people to work in those conditions for 12 hours a day. And to see the individuals at the end of their shift, still smiling, having technical discussions with the project manager, that is pretty impressive, especially after a long day, doing little touch ups, dragging heavy equipment around the boiler and they’re still happy about it because they know that you’re happy. I think, it speaks incredibly well of IGS’ management team, that they can have those kinds of people working for them.

Ed:

How has the thermal spray project execution evolved over the years?

Joel:

When I first started working with the IGS team in 2007, it was kind of a black box. I’m a very inquisitive individual and I wanted to understand the process. And so, I started getting more involved talking to the project manager on site, getting more detail and then really understanding the purpose of the thermal spray on the tubes. And for us it was two-fold: there was corrosion and then also erosion.

Accommodating Shrinking Budgets

And as budgets got thinner, we needed to figure out how we can do more work with less money. We started developing different specifications for different areas of the boiler. This increased the difficulty of the project.

Communication

One of the neat things that I saw that evolved over time was the communication between the client, myself, and the IGS project manager and even down to the individual team members, we developed a very good trust relationship there. From the first day that they came on site, we involved them in the inspection process, as if we’re showing them what we’re looking for and then that helped them understand what our problems were.

QA/QC Program

On the quality side, I have seen the evolution of the QA/QC program, where we could start tracking thermal spray down to a very small block. The last unit that I worked on was extremely complex as far as the corrosion process and the erosion-corrosion process goes. We needed to do more with less and so we had to really come up with a program that would allow us from year to year to be able to see what’s going on, how the thermal spray application is working and then what we can do to improve the reliability of the unit.

Ed:

What advice might you have for other plant personnel that are in similar positions, making decisions around thermal spray? What might you be able to pass on in terms of lessons learned?

Joel:

I think, you’ve got to start with a really good inspection. You’ve got to have some detailed numbers. I’m a big fan of the high-resolution ultrasonic thickness testing program. And then you have some open discussions about the operation of the unit, your fuel, any tube failures, and all aspects of what’s going on. What is the UT data telling you? What is your visual inspection telling you? And then have that conversation way prior to the application process of thermal spray, so that a work scope can be developed. And so that you can start putting together a budget and then prioritize your areas.

This was something that we always did at the beginning of the outage. We will always sit down, discuss anything that’s changed in the unit such as fuel, operating variables, just so that IGS was aware of the process so that when they’re performing their inspections, they keep that in the back of their mind.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.