SMARTGard®: HVTS Stops Alloy 625 Weld Overlay Corrosion in a WtE Boiler

Stopping Fireside Corrosion in WtE Boiler

A waste to energy boiler was experiencing fireside corrosion. Shop applied Alloy 625 weld overlay was showing signs of premature accelerated degradation. IGS was contracted to apply an HVTS cladding on top of the weld overlay in situ to stop corrosion and ensure the reliable and safe operation of the boiler.

After 10 months in service, the IGS thermal spray solution had no defects. As a result, additional areas of degrading Alloy 625 were protected with HVTS, which shown excellent result after 4 years in service.

Renergia Perlen

The Renergia waste incineration plant is a joint effort of all waste disposal associations from Central Switzerland and Perlen Papier AG.

Renergia Zentralschweiz AG is responsible for more than just recycling the waste from Central Switzerland. At the same time, it supplies Perlen Papier AG with process steam, the district heating networks Rontal and Emmen with hot water and supplies electricity for approx. 44,000 households.

Following two years of construction, the Renergia Waste to Energy plant went into operation in 2015.

WTE Boiler Fireside Corrosion of Alloy 625 Weld Overlay Cladding

The Hitachi Zosen Inova (HZI) furnace installed at Renergia is an inclined moving grate four-pass waste to energy boiler with an external economizer. The boiler’s thermal capacity is 47MW with the steam flow of 58 t/h and steam pressure of 41 Bar at 410°C.

Alloy 625 weld overlay was shop-applied on the fireside water wall panels to protect the WtE boiler tubes from fireside corrosion. After months of operation, an inspection revealed accelerated degradation of the Alloy 625 just above the grate.

Several solutions were considered to manage alloy 625 loss and improve reliability and lifetime of the water walls, including replacement, field applied weld overlay and thermal spray.

Evaluation of Alternatives

The replacement of affected water wall sections with new tubes would have been time-consuming and expensive, considering the estimated frequency of replacement of 5 years or less.

Like-for-like weld overlay repair is an intensive and time-consuming solution. It requires preliminary grinding of the degraded surface layer prior to the application of a new weld overlay. Moreover, both aforementioned solutions wouldn’t exactly solve the problem, as the same corrosive media attacking existing weld overlay would still be present.

The third option was thermal spray. “Thermal spray” technology had mixed results in boiler applications and the plant invited 4 thermal spray vendors to perform test applications on different sections within the boiler. Each vendor was given a side wall inside the 2 lines. Out of the 4 claddings applied, only 2 delivered satisfactory results. IGS HVTS solution was found to be the best, both in terms of performance and capacity. Multiple IGS HVTS guns can be operated inside the boiler at the same time with no capacity limitations.

Supported by comprehensive laboratory testing and extensive field experience IGS HVTS Alloy Cladding has no issues with permeability or disbondment and can offer lasting protection, where other technologies fall short. The test application results and additional references convinced the head of maintenance to choose IGS HVTS as the solution to their problem.

HVTS Application

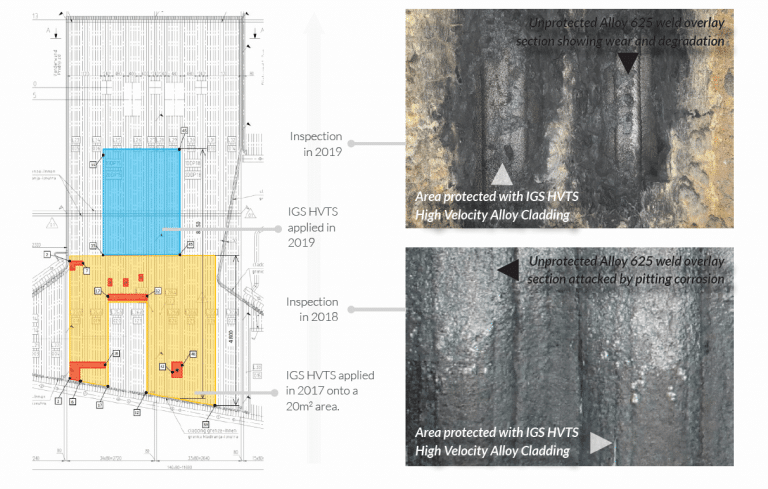

IGS HVTS application took place in 2017 on a 20m2 area located on the left membrane wall at the very low furnace of the moving grate WtE boiler above the refractory. The plant also had a thermal spray (TS) coating applied by a different vendor on the right-hand side of the membrane.

These areas were then inspected in 2018 to determine whether HVTS and other vendor’s TS were successful at stopping the weld overlay (WMO) degradation. The inspection of the HVTS/WMO interface showed that the area clad with IGS HVTS was no longer affected by corrosion. Unprotected Alloy 625 WMO and other vendor’s TS, on the other hand, both continued to degrade.

It was decided to extend the scope and apply HVTS alloy cladding onto an additional ~20m2 area in 2019. An inspection later that year, in August 2019, confirmed the following. The areas protected with high-velocity thermal spray (HVTS) alloy cladding were not exhibiting any pitting corrosion or wastage. Adjacent unprotected Alloy 625 weld overlay sections were showing signs of wear and degradation.

HVTS effectively protected the existing WOL and its use was recommended to be used in other areas

Weld Overlay Protection: Inspection and Results

IGS SMARTGard®: HVTS Application in 2017, 2019, 2020 and 2022

Markus Benz, head of maintenance at Renergia Zentralschweiz AG, commented:

“IGS Europe s.r.o. was selected in November 2017 to apply ~20m2 of its IGS material using HVTS technology. IGS’s team mobilized efficiently and performed the expected scope of work within the tight requested schedule.

“After 10 months in operation a short inspection was performed in September 2018 confirming good coating performance. As a result, another area was ordered for application in January 2019, 2020, and most recently 2022. Early January a deeper inspection confirmed the good overall behaviour of the cladding after 14 months in operation. The protected area has been doubled, so we expect to operate safely until our next turnaround in 18 months.

“IGS has successfully applied the contracted scope within the critical path in a highly professional manner, with reliable and transparent communication.”

Second Boiler

After three years of successful service, in 2021 the customer invited IGS to protect weld overlaid panels with IGS HVTS cladding in the second WtE boiler.

Implementation:

The application of IGS HVTS cladding was carried out in multiple phases:

Line 2:

2017: Original application of 24 m²

2018 Inspection: ~1% defect refurbished

2019: Additional scope of 20 m²

2020: Additional scope of 51 m²

2022: Additional scope of 38 m²

Line 1:

2017-2019: Two other thermal spray companies were used

2021: 35 m², partly replacing failing 3rd party application

2022: Additional scope of 38 m²

2024: The HVTS cladding was found to be in great condition,

so just several additional square meters were added

2020 Inspection and Results

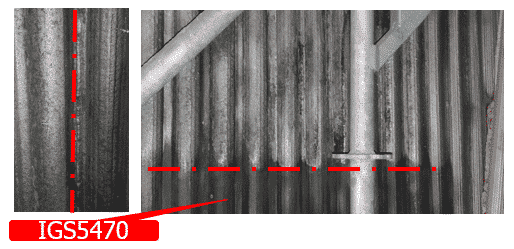

The latest inspection in 2023 has confirmed that HVTS IGS5470 is performing in line with expectations and is protecting weld overlay areas from further corrosion.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.