A Hot-spot Solution: Online Refractory Repair Saves Millions in Production Loss

The Burning Issue: Hotspots on a Roof in a Reformer

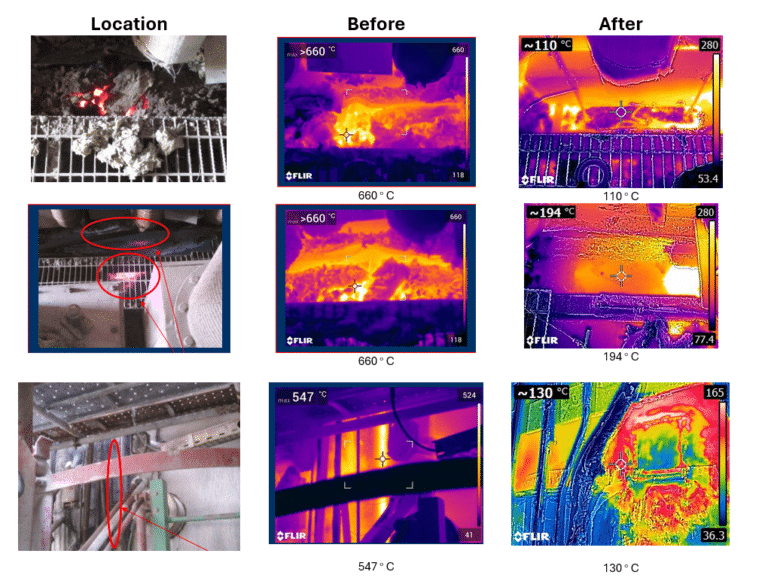

A petrochemical plant in the Middle East faced a critical problem with more than 10 hotspots on the roof of a roof fired reformer. This issue had persisted for almost a year, but the situation had escalated when some material fell, exposing the flames of the burner. The conventional repair method would require a unit shutdown for approximately three weeks, posing significant operational and financial risks.

The High Stakes: Safety Hazards and Financial Implications

The hotspots presented a serious HSE (Health, Safety, and Environment) hazard, with some areas now open and exposed. The risk of further hotspot propagation loomed large, threatening an unplanned shutdown. Financially, a three-week production loss could cost the plant an estimated USD 12 million.

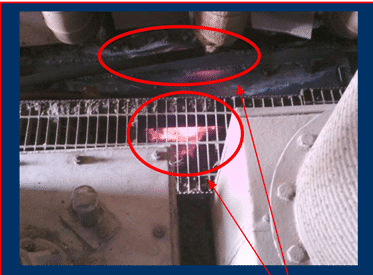

Hot spots on the fired heater caused by refractory failure

Initial Attempts: Temporary Fixes Fall Short

The plant initially tried steam purging and plate welding to address the issue. However, these methods provided little relief, and the problem persisted. It seemed that a complete shutdown was inevitable.

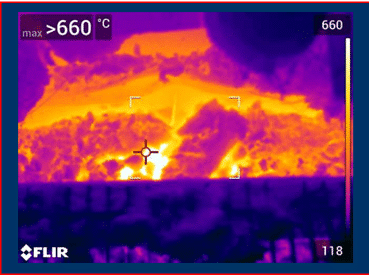

Infrared view of the hot spot

A Glimmer of Hope: Considering Online Repair

Having successfully repaired a hotspot online in a transition area previously, the plant began to consider this as a potential solution. However, repairing hotspots near burners and process tubes presented a unique challenge.

There was limited access to perform the repair

The Decision: Choosing Online Repair

After careful consideration and a detailed explanation from IGS experts, the plant gained confidence in IGS’s capabilities to perform the online repair. The potential to avoid production loss, prevent an unplanned turnaround, and ensure safe execution made this option particularly attractive.

Read more benefits of Hot-tek online repair, here.

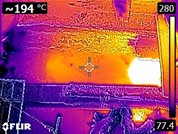

Infrared view of the hot spot after repair

Overcoming Challenges: Battling the Elements and Heat

The implementation process faced several obstacles:

- Adverse weather conditions with strong winds

- Extreme temperatures near the burner

- Close proximity to process tubes

To overcome these challenges, the team:

- Planned the hot-spot repair sequence to minimize heat exposure

- Implemented IGS’s safe execution program based on heat exposure levels

- Utilized state-of-the-art Personal Protective Equipment (PPE)

The Outcome: A Narrow Escape and Long-Term Benefits

The online repair successfully averted an immediate shutdown. Although the plant faced a shutdown two weeks later due to an unrelated issue, the plant was able to restart in just three days, due to the already completed refractory repair.

The biggest success of this project was the ability to repair the most difficult-to-access area of the fired heater without a prolonged shutdown.

Locations of hot spots and infrared imagery before and after IGS Hot-tek repair

Lessons Learned: The Value of Online Fired Heater Services

This case study highlights the importance of considering online repair services to avoid unplanned shutdowns and the associated production losses. Companies facing similar challenges should explore innovative solutions that can maintain plant operations while addressing critical issues.