Scale Removal on Live Furnace Leads to Instant Fuel Savings

The Impact of Hot Tube Descaling on Fuel Savings

In the refining industry, scale accumulation on furnace process tubes is a significant challenge, leading to reduced efficiency and potential safety hazards.

Addressing these issues, IGS’s Hot Tube Descaling (HTD) technique was employed at a Jubail refinery, aiming to enhance operational efficiency and fuel

consumption reduction. This case study examines the effectiveness of the HTD process and its impact on overall

furnace performance.

Technical Solution:

Hot Tube Descaling (HTD)

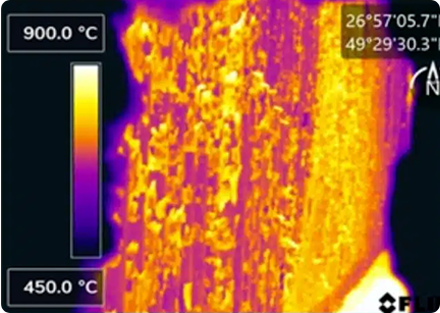

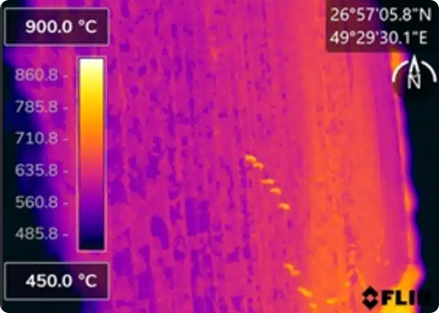

The HTD process offers a dynamic solution for removing radiant section process tube scale and fouling while the furnace remains operational. This method employs water-cooled lances for continuous, efficient scale removal, leveraging organic abrasive media that leaves no environmental footprint. Key benefits include:

- Improved fired heater efficiency by eliminating insulating scale.

- Lowered tube and bridge wall temperatures.

- Particular effectiveness in catalytic reforming units.

The environmentally friendly nature of the organic blasting media, which incinerates completely, ensures a safe, emission-free process, all while maintaining uninterrupted production

Process Tube Descaling

on Live Heaters

Tailoring the approach to the specific metallurgy of the process tubes, the IGS Team successfully removed semi-adherent loose scale. Emphasizing extensive surface area cleaning, the team carefully navigated to prevent damage to adjacent refractory surfaces, utilizing existing inspection ports for

lance insertion.

Results and Benefits: Fuel Consumption Reduction

Post-HTD implementation, the refinery reported a significant 3.5% reduction in fuel consumption.

This translates to substantial fuel savings and enhanced operational efficiency.

Return on Investment:

High-Temperature Descaling

in Furnaces

A detailed ROI analysis underlines the HTD project’s profitability. The projected payback period of less than five months, through fuel savings or increased throughput, highlights the cost-effectiveness of this innovative solution.

| Fuel Savings or Capacity Increase | 3.5% |

| Extra Monthly Profit | $642,600 |

Conclusion

The successful implementation of the HTD process at the Jubail refinery is a testament to the expertise and dedication of the IGS team. Their strategic approach in scale removal resulted in significant improvements in both operational efficiency and safety. The effective elimination of loose scale deposits allowed for more precise tube metal temperature readings, bolstering overall safety measures. A noteworthy 3.5% improvement in efficiency was observed, leading to a rapid payback period — 6 months based on reduced fuel consumption and just 1 month when considering capacity increase. This case study not only highlights the importance of proactive maintenance strategies but also showcases the IGS team’s pivotal role in achieving operational excellence and substantial cost savings in refinery operations.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.