HVTS® Cladding Improves Reliability of Heat Exchangers in Chlorine Service

In one of the Gulf region’s largest integrated chemical production complexes, chlorine gas cooler heat exchangers play a vital role in supporting continuous chlor-alkali operations. These shell-and-tube exchangers, located in a unit handling chlorinated gas streams and water-side cooling, were showing recurring signs of localized corrosion and weld deterioration during previous unplanned maintenance shutdowns.

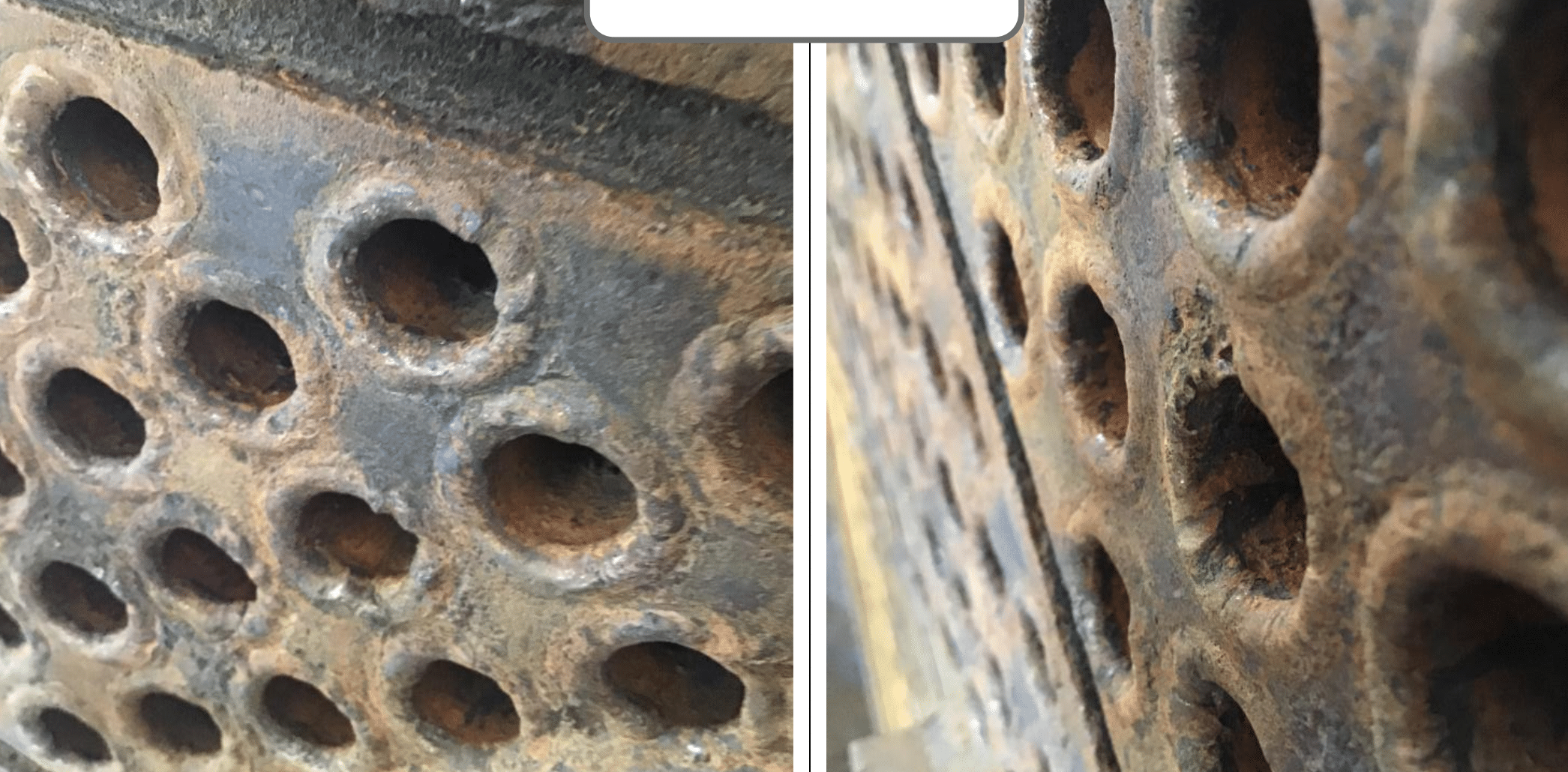

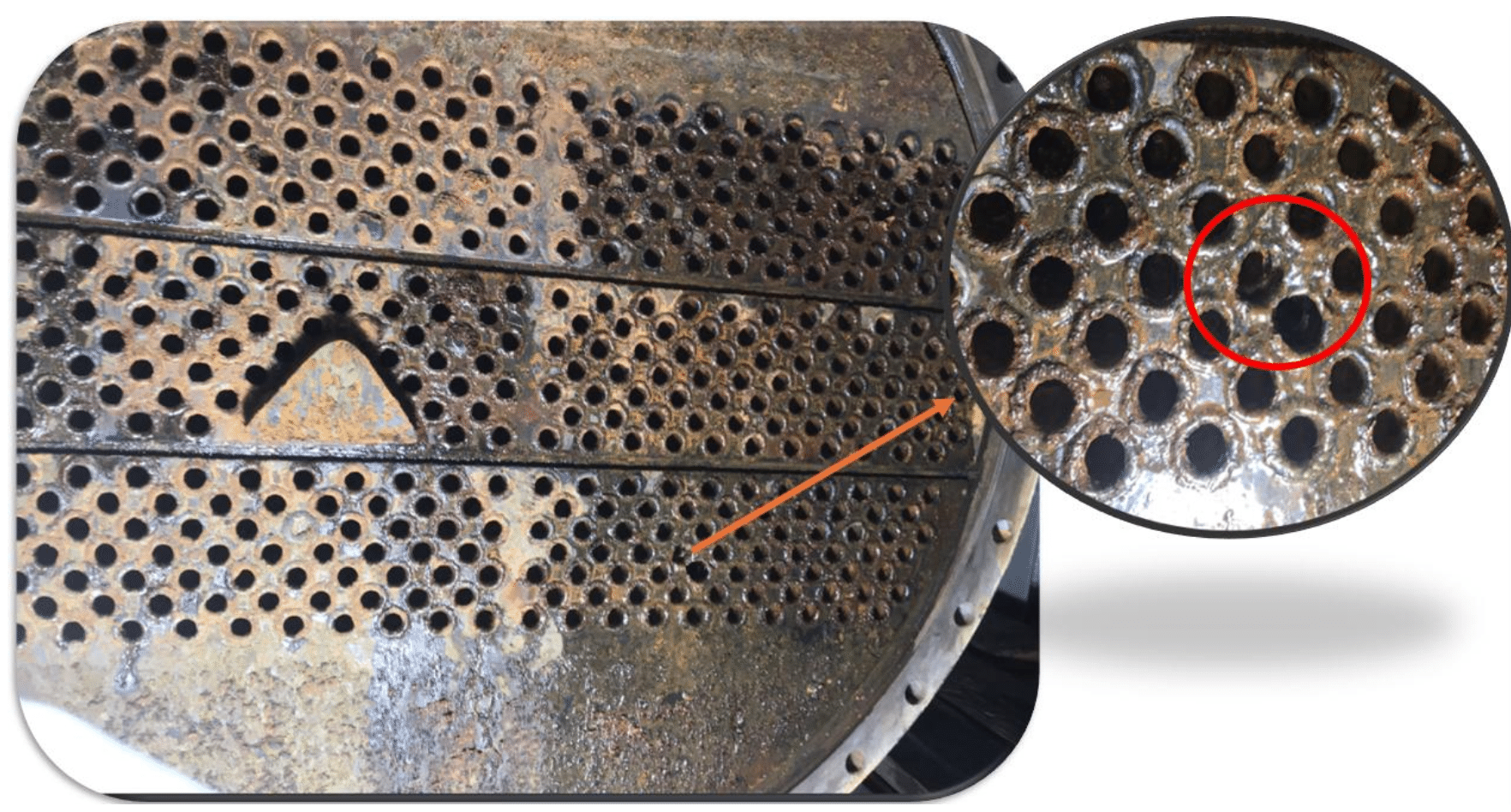

Detailed inspection revealed deterioration of tube-to-tube sheet (TTS) welds, and advanced pitting corrosion at several critical locations. Historic measures such as seal welding, plugging and the replacement of an entire tube sheet, had failed to tackle the metal degradation root cause, resulting in a risk to asset integrity and operational reliability.

With production targets at stake, the client needed a fast, durable, and highperformance solution to protect the tube sheet faces from chlorine-induced attack during their narrow emergency shutdown window.

Evaluating the Solutions Available

Repair methods such as seal welding, tube plugging, and tube sheet replacement were not tackling the root cause of the metal degradation problem. Searching for a long-term solution, the plant ultimately selected IGS and HVTS (High-Velocity Thermal Spray) for the following reasons:

- Ability to apply a long-term, corrosion-resistant solution in-situ.

- Capability to mobilize and execute rapidly within the short mechanical maintenance window.

- Demonstrated past success in similar chlorinated environments.

IGS Solution Delivery

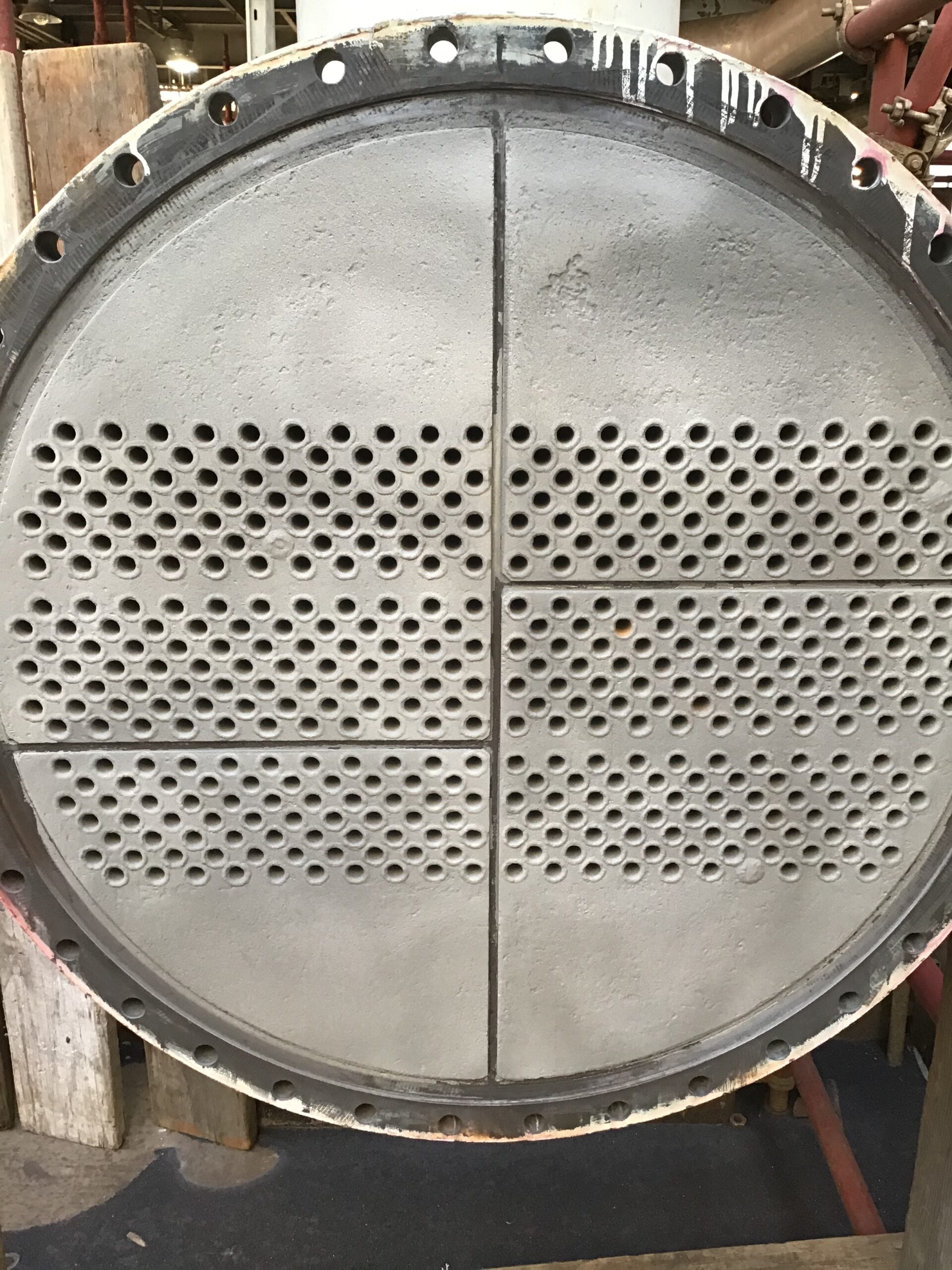

IGS deployed its proprietary HVTS cladding, a modified Hastelloy-based material engineered to resist pitting, erosion, and chlorine-induced degradation. The application covered six tube sheet faces across three exchangers.

The project included:

- Surface preparation.

- HVTS cladding of six tube sheet faces on the three exchangers.

- HVTS cladding validation through film thickness testing, profile mapping, and client-approved ITPs.

Zero safety incidents were recorded during execution, and the IGS team completed the project ahead of schedule, supported by round-the-clock collaboration with the client’s engineering and reliability staff.

Quantifiable Impact and Proven Results

Service Life Extension

Restored integrity across six severely degraded tube sheets, mitigating the risk of future leaks.

Schedule Efficiency

Full project completed in less than three days, beating the critical path timeline and enabling early handover.

Safety Performance

Zero incidents, with full compliance with client and IGS safety protocols.

By applying the robust HVTS alloy protection, the client reduced unplanned downtime risk and avoided potential replacement of the exchangers — an outcome that would have cost significantly more in both time and capital.

Testimonial

“This wasn’t just a corrosion fix. It was an opportunity to protect production continuity and eliminate a recurring problem, without the delays or risks of conventional methods. We delivered durability and certainty where it was most needed.” – Dennis Snijders, Sr. Director – Middle East, IGS

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.