Maximize Uptime Through Smart Inspection

Real-time insights to avoid unplanned repairs and reinforce boiler reliability.

Location: Power Plant, Philippines

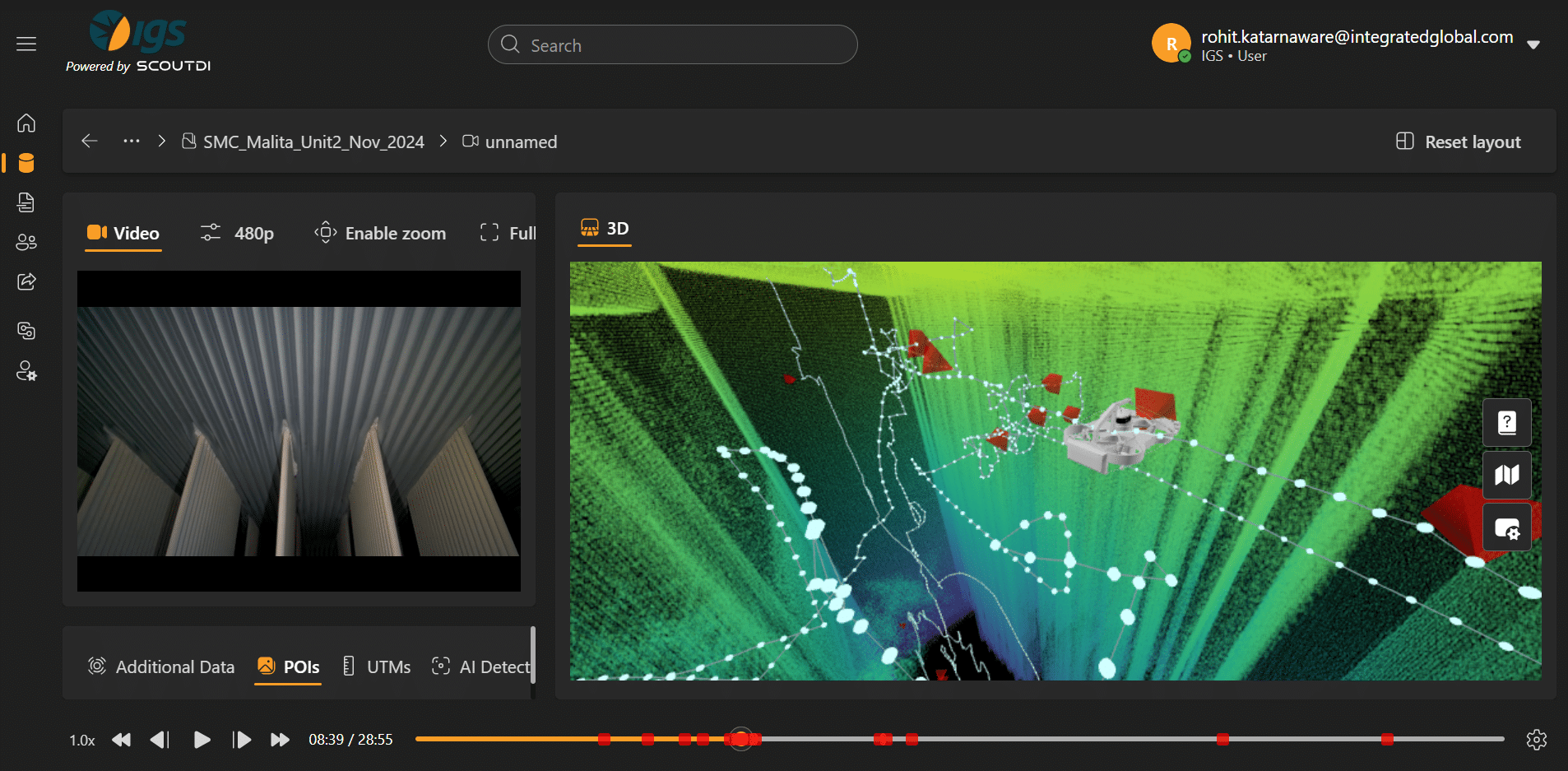

Application: Drone inspection in 150MW circulating fluidized bed (CFB) boiler

Proactive Insight During Unplanned Downtime

Taking Advantage of an Outage to Safeguard Future Operations

When an unavoidable ID fan issue forced an unexpected shutdown of one of the client’s CFB boilers, the team saw an opportunity to gain valuable insights into the boiler’s internal condition.

With no other major work scheduled inside, full scaffolding wasn’t justified—but the team still wanted a clear view of key components, including the refractory and tubes.

IGS proposed a drone inspection, marking the first time this technology was used by IGS in the Philippines. The plant had previously received IGS HVTS® cladding in 2022, and both parties were eager to verify its performance.

Inspection Objectives

- Evaluate the performance of previously applied High Velocity Thermal

Spray (HVTS®) cladding installed in 2022 - Identify any other anomalies while the boiler was offline

Efficiency Without Compromise

Full Visibility Without Delay or Disruption

The inspection utilized a high-performance drone – the first of its kind used by IGS in the Philippines. By accessing the boiler through two entry points, the drone achieved complete internal coverage within just 4 to 5 hours.

This innovative approach eliminated the need for scaffolding and enabled the inspection to begin almost immediately, saving the plant 2–3 days compared to traditional methods.

Findings Confirm Long-Term Protection

Validation of cladding performance and risk mitigation

The visual review confirmed the HVTS cladding remained in excellent condition, validating its protective integrity nearly two years after application. Areas with visible erosion outside the clad zones were noted but did not require immediate intervention. Other findings revealed cracks in the refractory material, which were promptly addressed by the plant team to prevent potential future boiler tube failures.

The drone inspection showed the HVTS cladding applied in 2022 to be in excellent condition.

The inspection revealed some cracks in the refractory, which were promptly addressed by the plant’s maintenance team.

Delivering Strategic Value Beyond Protection

Trust Built Through Performance and Partnership

IGS’s inspection emphasized its ongoing commitment to client success. It reinforced the performance of the cladding and provided SMC engineers with timely, decision-driving insights during a critical outage.

Precision insights. Proactive partnership. That’s Asset Vitality.

“We expected the cladding to be in good condition, having been in service for only two years, and having undergone one previous inspection. What really mattered was giving the client real-time, actionable data during a critical moment, helping them avoid a potential future shutdown.”

– Rohit Katarnaware

Country Manager – Philippines, IGS

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.