Remote Vessel Fouling Removal for PDH Plant Surge Pot

Summary

A national petrochemical company in Saudi Arabia faced a significant fouling issue inside a surge pot at its Linde/BASF PDH (Propane Dehydrogenation) plant.

Heavy, tightly adherent deposits from long-term catalyst build-up contaminated feed and heavily scaled the bottom dished end. Access was extremely limited: the only entry was a 360-mm funnel pipe into a 1200-mm cylindrical vessel, making conventional cleaning methods impractical.

Conventional Solution Limitations

Without an innovative approach, the facility would have needed to:

- Lift the surge pot out of position

- Place it horizontally

- Create access points for human entry to manually descale the walls

- Reinstate the vessel wall with welded patches

- Lift and reinstall the vessel back into position

This conventional approach would have significantly extended the turnaround (TAR) time, increased costs, and introduced additional risks associated with lifting operations, man entry, and structural modifications to the vessel.

The IGS TubeTech™ Solution

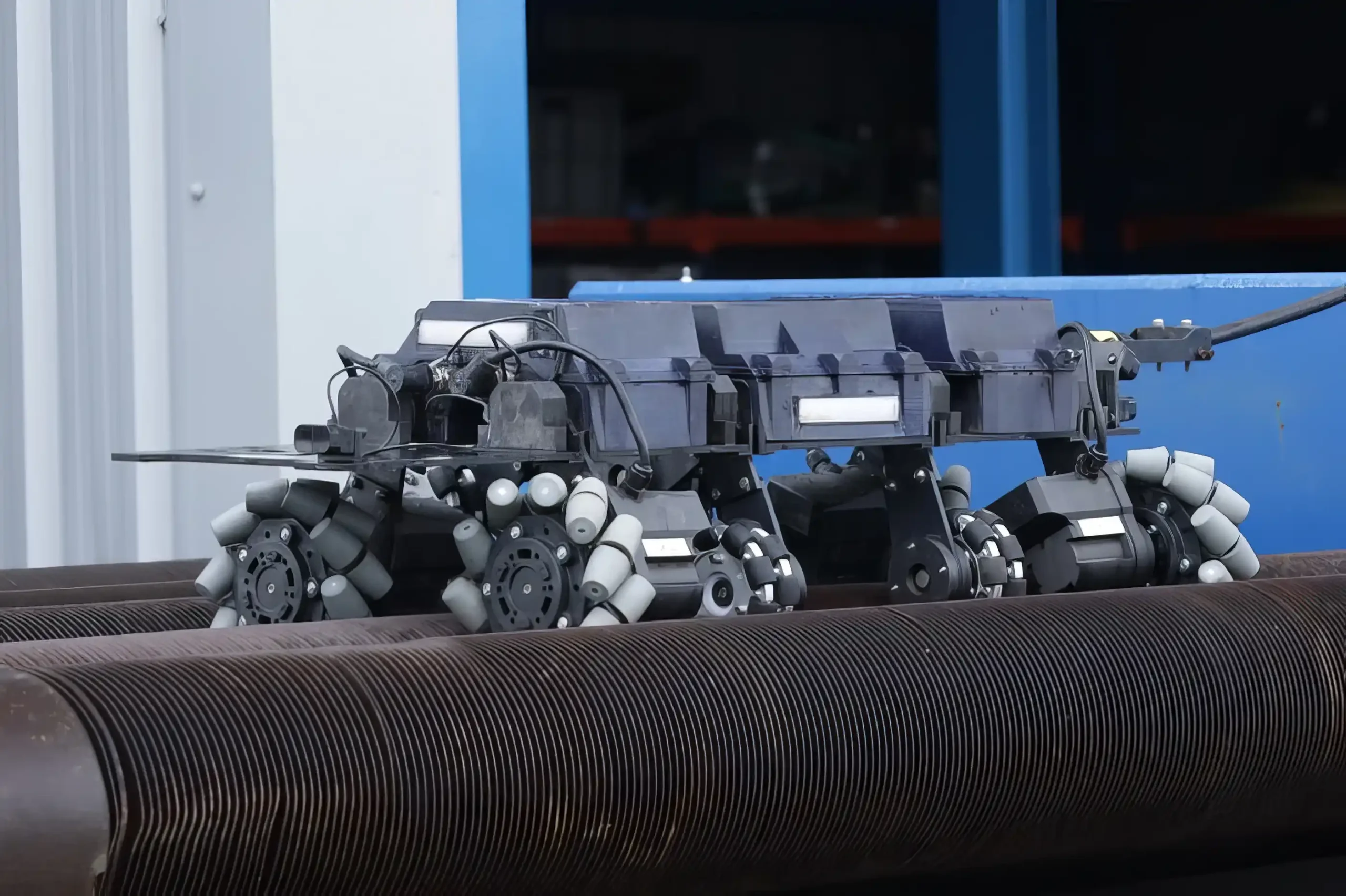

The plant approached IGS TubeTech™ for an engineered, fast, non-invasive solution. IGS deployed its proprietary high-pressure cleaning technology to address this challenge.

Key Solution Elements:

- Vessel fouling removal technology

- No requirement for human entry into confined spaces

- Minimal strip-down of the vessel

- Ability to reach difficult access areas, including dished ends

- Maintained the vessel in a vertical position throughout the cleaning process

Key Benefits

- Eliminated the need for vessel repositioning and man entry

- Completed the work faster than conventional methods

- Avoided cutting and rewelding of the vessel

- Significantly reduced TAR time

- Greater than 50% cost savings compared to conventional methods

- Enhanced safety by eliminating confined space entry

- No structural modifications required to the vessel

Project Execution

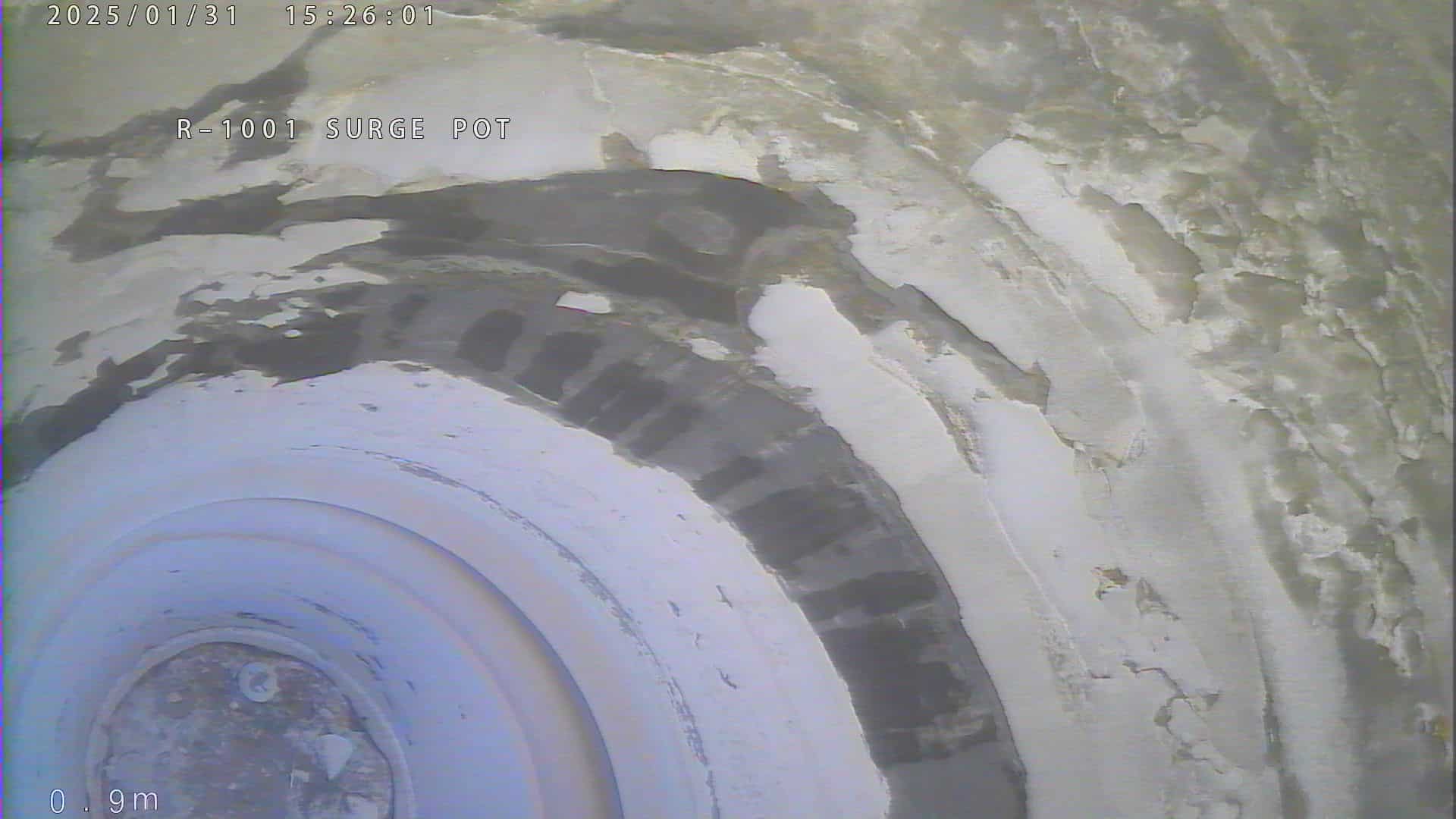

The project was executed from January 30 to February 2, 2025. The surge pot was left in place, which allowed for remote fouling removal activities. The IGS team successfully deployed their specialized equipment through the limited access points to clean the internal surfaces.

Results and Benefits

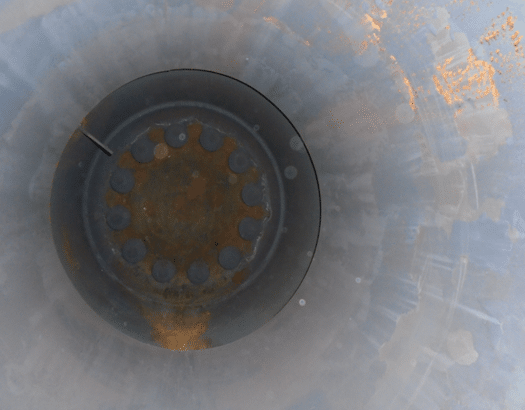

The fouling removal technology successfully achieved bare metal cleanliness standard for the internal surfaces of the vessel. The plant’s inspection department conducted the final inspection using borescope video technology, confirming the successful cleaning of the internal shell and bottom dish end of the surge pot.

Continuing Relationship

In the same mobilization, IGS TubeTech™ also cleaned two fired heater convection sections using its patented ROV technology, demonstrating the versatility of its remote cleaning technologies and strengthening its ongoing relationship with the facility.

The success of this operation has positioned this asset for regular inclusion in scheduled turnaround maintenance work, ensuring continued optimal operation with minimal downtime.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.