Online Scale Removal on Fired Heater Improves Efficiency and Cuts Fuel Consumption

High Temperature Scale in Furnaces

In refineries, the accumulation of scale on furnace process tubes can lead to decreased thermal performance, reduced fired heater efficiency, and potential safety risks. To address these challenges, the IGS Team implemented a Hot Tube Descaling (HTD) process at a refinery in Jubail, Saudi Arabia. This case study aims to evaluate the effectiveness of the online cleaning method and its impact on fuel consumption reduction, CO₂ emissions, and overall fired heater performance.

Technical Solution

Hot Tube Descaling (HTD) removes radiant section scale and fouling during live heater operation, without requiring a shutdown.

Water-cooled lances ensure continuous scale removal and maximum cleaning efficiency while the fired heater remains online. The process uses organic abrasive media, resulting in zero impact on emissions or opacity.

Existing inspection ports are used to introduce the lances.

Key Benefits:

-

Improves fired heater thermal efficiency by removing insulating scale

-

Lowers tube surface temperatures, improving tube life

-

Reduces bridge wall temperatures, improving overall heat balance

-

Highly effective in catalytic reforming furnaces and other high-temperature process units

The organic blasting media is fully incinerated during the service, ensuring no environmental impact. This online cleaning solution is safe, eco-friendly, and ideal for removing years of scale and fouling with no interruption to refinery operations.

Process Tube Descaling on Live Heaters

By considering the process tube metallurgy, the IGS team identified that the HTD service was ideally suited to remove the semi-adherent loose scale on the tube surface.

The team focused on cleaning the maximum possible surface area while protecting adjacent refractory materials.

Lances were strategically inserted through existing inspection doors, enabling targeted scale removal.

Results and Benefits: Fuel Consumption Reduction

The chart in this case study (page 3) demonstrates the substantial ROI from HTD. Whether through fuel savings or increased throughput, the refinery saw:

-

3.5% improvement in fired heater efficiency

-

$642,600 in extra monthly profit

-

Payback period of under 5 months

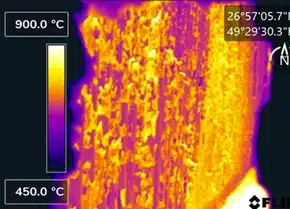

Before HTD: High surface temperatures and reduced heat transfer

After HTD: Optimized thermal profile, enhanced reliability, and measurable energy savings

Conclusion

The implementation of the IGS HTD solution at this Saudi refinery led to significant gains in efficiency and performance.

The successful removal of scale deposits enabled more reliable tube metal temperature (TMT) measurements, contributing to operational safety.

The 3.5% increase in energy efficiency delivered:

-

6-month payback based on fuel savings

-

1-month payback based on capacity increase

This case study showcases the importance of proactive furnace maintenance strategies and highlights the value of online scale removal technologies like HTD in achieving refinery operational excellence, sustainability goals, and profitability improvements.

The IGS Surface Solutions Package

IGS delivers online fired heater services, including:

• Hot Refractory Repair • Hot Convection Cleaning

• Hot Tube Descaling • Hot Vacuum Service • Hot Inspection Service

Decades of experience, unparalleled customer support and commitment to excellence solidifed our position as a global leader in fired heater maintenance. Over the last 10 years, over 50 fired heater hot spots have been successfully repaired with no additional impact to production.

I’m here to help

Larry Emch

IGS Subject Matter Expert

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.