Weld Build-up Services for Pressure Vessel Repair

Restore structural integrity and extend the life of your most critical pressure vessels and process equipment.

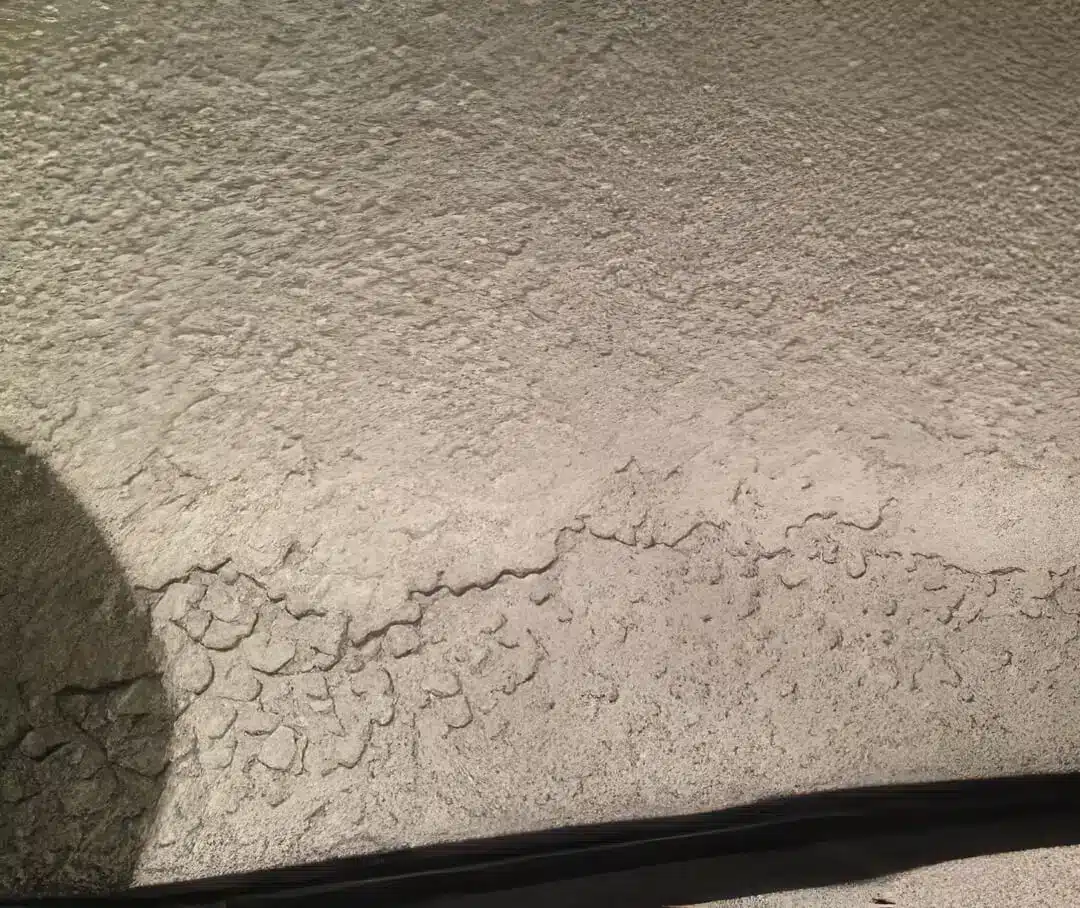

IGS’s weld build-up services offer a reliable and field-proven approach for pressure vessel repair, restoring thinning wall sections, re-establishing pressure boundaries, and preparing surfaces for advanced corrosion-resistant coatings such as HVTS® or weld overlay. Designed specifically for harsh industrial environments – where erosion, corrosion, and mechanical wear jeopardize performance – our automated pressure vessel welding methods deliver both immediate restoration and long-term protection, all while reducing downtime and cost.

The Challenge

- Severely corroded or eroded pressure vessel components approaching minimum wall thickness

- Aggressive corrosion/erosion in process vessels, columns, and drums

- Time-sensitive turnarounds and complex pressure vessel repair procedures

- Simultaneous need for restoration and future protection

Our Solution

1. Precision Weld Build-up for Pressure Vessels

IGS restores base material back to its design thickness using an automated weld build-up process that delivers mechanical strength and metallurgical integrity.

- Restores base material to nominal/design specifications

- Controlled parameters to ensure maximum deposit quality

- Minimal heat-affected zone

- Full metallurgical bond with base material

- Automated process ensures consistency and quality

2. Optimized Surface for HVTS® or Weld Overlay

After weld build-up, surfaces are prepared for HVTS®—our advanced high-velocity thermal spray coating or weld overlay. This combined repair and protection strategy dramatically improves pressure vessel service life.

-

Engineered for bonding strength and long-term corrosion resistance

-

Applied in-field with minimal disruption to operations

Benefits of IGS Weld Buildup

-

Pressure Vessel Longevity: Restore and protect columns, reactors, and drums from corrosion and erosion

-

Cost Efficiency: Reduce maintenance and replacement frequency with reliable pressure vessel welding

-

Schedule Reliability: Precise, automated techniques improve turnaround predictability

-

Code-Compliant Repairs: Align with best practices for pressure vessel repair procedures

-

Material Flexibility: Works with stainless steel, Inconel, and other alloy systems

Weld Build-Up & HVTS for Lasting Pressure Vessel Integrity

Our Welding Services

Extend asset life and safeguard critical infrastructure with IGS’s industry-proven automated welding services

- Automated Field Overlay

- Weld Build-up

- Speciality Welding

Looking for a complete pressure vessel repair and protection solution?

Explore our Automated Field Welding Services to combine weld buildup, cladding, and overlay techniques—ensuring total process vessel integrity and performance.