Restoring Oleflex Heater Efficiency

Efficiency Issues in Three Oleflex™ Charge Heaters

A leading high-quality polymer and petrochemical products producer in Jubail, Saudi Arabia, known for its commitment to innovation and sustainability, faced efficiency issues in three charge heaters, part of the UOP Oleflex™ process unit. After a thorough evaluation, it was determined that the primary cause of the Oleflex Heater efficiency problem was convection section fouling, resulting from the accumulation of refractory fibers and other debris.

The Challenge

Restoring Oleflex Heater Efficiency

The petrochemical company recognized the need for a reliable and efficient solution to address the fouling issue and restore the Oleflex heaters and their efficiency to their design parameters. Considering the company’s focus on innovation and sustainability, it sought a proactive approach that would not only resolve the immediate problem but also contribute to its operations’ overall reliability and optimization.

The Solution: IGS Robotic Convection Section Cleaning

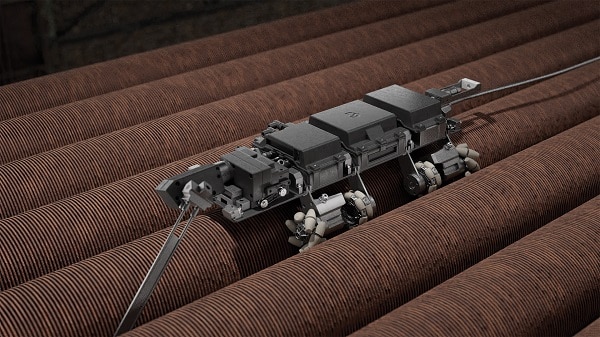

The petrochemical company turned to IGS, a specialized provider of robotic and field-applied solutions for industrial applications. IGS proposed the deployment of its robotic convection section cleaning ROV (remotely operated vehicle) to remove the accumulated fouling and restore the heaters’ efficiency.

Image: TubeTech™ ROV in action with its lance cleaning the bottom section of the finned tube bundle

The IGS robotic cleaning solution offered several key advantages:

Effective Fouling Removal: The ROV was equipped with a high-powered cleaning lance and advanced maneuvering capabilities, allowing it to effectively dislodge and remove the refractory fibers and debris from the convection sections of the heaters.

Improved Safety: By utilizing a remotely operated robotic system, the cleaning process was conducted without exposing personnel to the potentially hazardous conditions within the heater convection sections, enhancing the overall safety of the maintenance activities.

Sustainable Approach: The IGS solution aligned with the petrochemical company’s commitment to sustainability, as the robotic cleaning process generated minimal waste and reduced the need for traditional manual cleaning methods that can be more resource-intensive.

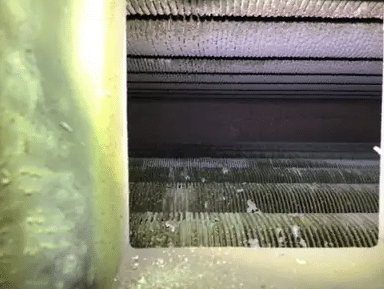

Image: Convection section condition after TubeTech™ ROV service

Implementation and Results

Efficiency Restored in Oleflex Heaters

The IGS team deployed the robotic convection section cleaning ROV carefully navigating the device through the three affected Oleflex heaters. The robotic system effectively dislodged and removed the accumulated fouling, restoring the convection sections to their design specifications and therefore the efficiency of the Oleflex heaters.

- The targeted and thorough cleaning process effectively removed 90-95% of the accumulated deposits, restoring the heater to its design parameters, improving overall plant performance and productivity.

- The sustainable and safe nature of the robotic cleaning solution aligned with the company’s commitment to innovation and environmental responsibility.

Conclusion of Another Successful Convection Section Cleaning Project

The successful deployment of the IGS robotic convection section cleaning solution at the petrochemical company’s facility demonstrated the power of innovative and sustainable approaches to addressing complex industrial challenges. By leveraging advanced robotic technology, the petrochemical company was able to efficiently restore the efficiency of its Oleflex charge heaters, while also aligning with its strategic objectives of continuous improvement and environmental stewardship.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.