Twice as Good and Twice as Fast. SMARTGard®: Reliable Boiler Tube Protection

Most Modern Power Plant

The plant was completed and commissioned in 2010. The power plant’s production capacity is 180,000,000 kWh per year. The heat and energy produced is mainly used by a paper mill and the local municipality’s district heating company.

The power plant primarily uses household and industrial waste as an energy source. The fuel comes from municipalities as well as other stakeholders in the region. Today, energy is extracted from 70,000 tonnes of waste, which corresponds to the energy consumption of 11,000 small houses.

PROBLEM

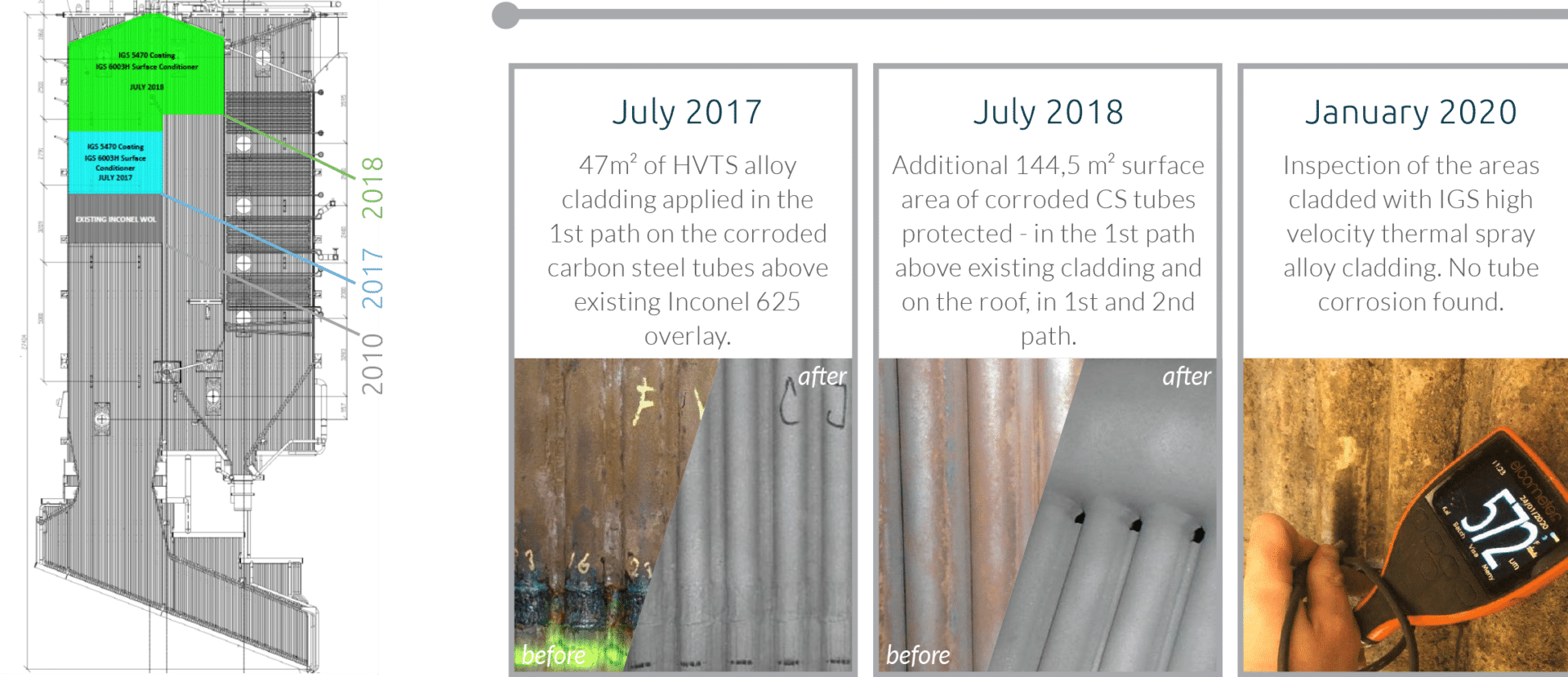

After discovering metal wastage in 2014 and having to replace a panel section in 2016, engineers decided to protect new panels with thermal spray cladding.

SOLUTION

Integrated Global Services (IGS) proposed SMARTGard®, a high velocity thermal spray (HVTS) alloy cladding solution, which was applied within 3 days, saving time and associated costs.

Inspections have confirmed IGS cladding to be intact after years in service.

Boiler Metal Wastage

In summer 2014 corrosion was identified on the unprotected boiler tubes, above the weld overlay section. New panels were installed to replace corroded sections, needing cost-effective protection, which would also be faster to apply than weld overlay.

Integrated Global Services (IGS) as well as another vendor proposed a solution. Due to the fact that IGS would be able to apply their thermal spray cladding within three days (as opposed to six days, as quoted by the other vendor) and their multiple references, the Power Plant has offered the maintenance contract to IGS.

2020 Inspection

Spot check inspection of the boiler in 2020 on both HVTS alloy cladding applications showed no reduction of metal thickness. The Power Plant’s boiler engineer, commented: “We are pleased with the service provided by IGS. Reliability and efficiency are very important for our plant. We focus on working with vendors that are able to deliver high quality results, ensuring we can continue our operations with minimal disruption”.

Routine Boiler Inspections

IGS have certified inspectors who are able to evaluate the performance of any boiler tube protection, highlighting areas of improvement and advising on a suitable solution for erosion and corrosion issues.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.