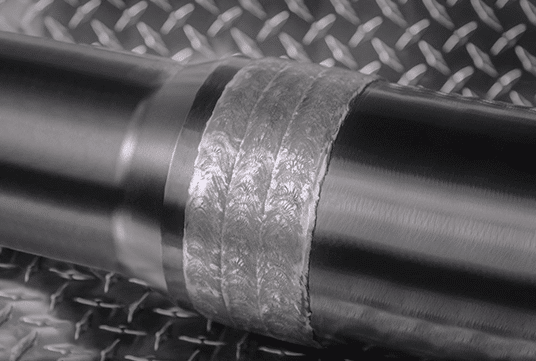

Armacor MStar™ - Drill Pipe Tool Joint Casing-Friendly Hardbanding

Revolutionary Material Technology

IGS has acquired Armacor MStar™, bringing revolutionary material technology to create the most effective casing-friendly hardbanding solution available. With exceptional surface hardness (up to 1100 Vickers) and an incredibly low coefficient of friction (0.11 to 0.14 against steel), MStar™ sets new industry standards for drill pipe tool joint protection.

Key Benefits:

- High hardness hardbanding

- Most casing-friendly solution

- Lowest friction in the market

- Zero failures in the field

- Superior protection against wear

- Less tool joint wear

- Excellent reapplication properties

The Technology Advantage

Surface smoothness and hardness are critical to minimizing wear, preventing galling, and providing the best casing protection. MStar™ has the unique ability to transform from a crystalline to amorphous microstructure under conditions of friction and abrasive wear. The result is lower friction than all other hardbanding products on the market, ensuring that MStar™ provides the best casing protection available.

Technical Specifications:

- Surface hardness: up to 1100 HV (Vickers Hardness)

- Weldable by MIG process

- Cored wire construction

- Available in wire spool packaging

Applications:

- Open Hole Operations

- Cased Hole Operations

- Reapplication Projects

The IGS Difference

With proven amorphous alloy technology, IGS offers the best hardbanding solution for each drilling environment. Whether for open holes, holes with various casings, or reapplication, we welcome side-by-side field test comparisons.

About IGS

Integrated Global Services (IGS) is a full-service provider of coating protection for multiple industries including Energy, Power Generation, Pulp & Paper, and Mining, among others. The addition of Armacor MStar™ technology further strengthens our comprehensive suite of protective solutions.

Talk to us about a Free Technical Evaluation.