How did HVTS Cladding Protect 2,000 Sq. Ft. of Boiler Tubing from Fireside Corrosion in 5 Days?

Scheduled Shutdown

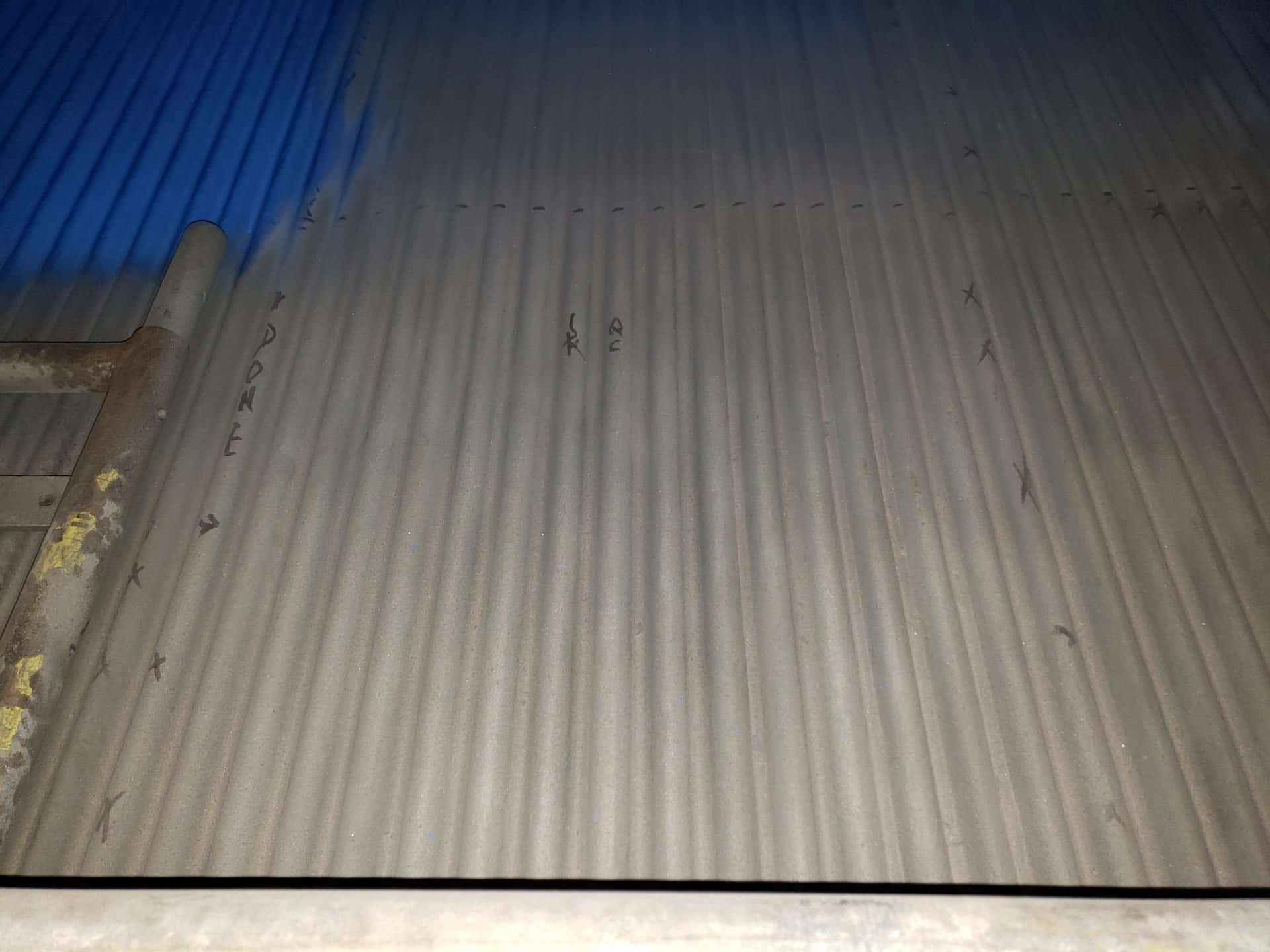

The unit was in a scheduled outage in October 2019, at which time the fireside of the tubes in the boiler were inspected by robotic UT. Wastage was discovered on both sidewalls above the existing field applied overlay, rear wall slope and burners, and front wall slope and burners. The type of damage is typical for opposed wall fired pulverized coal boilers operating in a reducing atmosphere with low NOₓ burners.

Rapid Response

IGS’ HVTS Cladding service was used to install 5450 EPRI Proven HVTS Alloy Cladding over the damage zones. IGS offered a rapid response and addressed the areas during the week of November 4, 2019. The IGS solution is a rather fast application – a total of 2,000 square foot of boiler tubing was protected with HVTS in 5 short days.

Safety First

The project was executed in accordance with the IGS Safety Program. Safety is, and always will be Integrated Global Services’ first and highest priority. Our Management Team is dedicated to becoming the industry leader in Health and Safety while our excellent safety record bears witness to this fact. A continuous improvement process is utilized that enables all levels of personnel to take part in identifying and fixing hazards associated within the workplace. This is marked by our Safety Committee that involves members of all areas and levels of IGS.

Quality

IGS Thermal Spray projects are performed in accordance with the IGS quality control standards which have been developed in to meet customer requirements. All site work will be executed in accordance to the accepted Quality Control Plan (ITP/QCP) and accompanying method statement. The final project QC package will be issued along with this report.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.