Fiber Refractory Dusting Encapsulation Coating

Eliminate Convection Section Fouling by Encapsulating Refractory

Refractory Ceramic Fiber linings become friable in use. The surface fibers are readily transferred downstream from the radiant section by the flue gases and captured by finned convection section tubes. This effectively insulates the tubes and reduces the efficiency of heat transfer in the convection section. By applying a ceramic coating to the refractory surfaces in the radiant section, the loss of friable fiber and resulting build-up of fouling can be prevented, allowing for a cleaner and more efficient heat transfer process. This method not only eliminates fouling, but also extends the life of the refractory, reducing maintenance costs in the long run, resulting in consistent performance and cost savings.

The Problem

Over time refractory ceramic fiber becomes friable. This friable dust is entrained in the post combustion flue gases and gets carried downstream, fouling convection section tubes and catalyst banks.

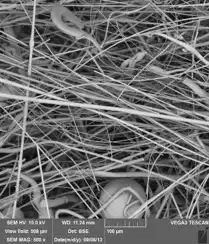

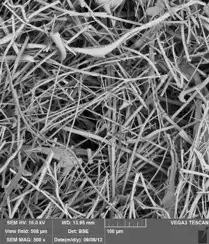

Figure 1 shows new ceramic fiber under Scanning Electron Microscopy (SEM). The Fibers are continuous and intact. After heat exposure, long strands break down into smaller pieces, which are carried downstream and comprise the majority of convection section fouling, shown in figure 2.

Figure 1: New Ceramic Fiber

Figure 2: Ceramic Fiber After Heating

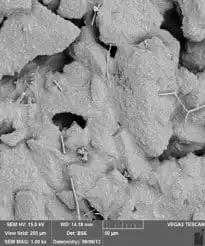

Figure 3: Cetek Coated Ceramic Fiber

The Solution

Cetek Ceramic coatings effectively encapsulate the surface fibers, forming a composite structure (Figure 3). The ceramic fibers are contained within the matrix and are prevented from escaping to the flue gases.

The ceramic coating is designed for use up to 1426°C (2600°F) and has a long life, approximately 6-8 years; totally preventing fouling from ceramic fiber linings, on both new and existing/old applications.

The Benefits

Lower Maintenance Costs

Preventing convection section fouling eliminates the costs associated with its cleaning.

Improved Efficiency

No fouling means the furnace can reliably operate at its expected design efficiency.

Long Term Solution

Cetek refractory encapsulation lasts for 6-8 years/2-3 turnarounds.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.