Understanding Oil & Gas CO2 and NOx Emissions, and the Science Behind Reducing Them

Oil refineries, petrochemical, and chemical facilities are widely considered some of the largest contributors to nitrogen oxides (NOx), and carbon dioxide (CO2) emissions which adversely affect the environment.

Fired heaters emit an estimated 400 to 500 million tons of carbon dioxide (CO2) every year, with at least 73% of average refinery CO2 emissions coming from combustion. Refineries and petrochemical plants are therefore under increasing pressure to reduce emissions, while also looking for ways to reduce fuel consumption amid rising fuel prices.

What are CO2 Emissions?

CO2 emissions are derived solely from burning hydrocarbon fuels – natural gas, or refinery-derived gas. In relation to refineries and particularly fired heaters, any reduction in hydrocarbon fuel usage will naturally result in lowering the CO2 emissions from a fired heater.

How Has Global CO2 Emissions Changed Over Time?

According to an Our World in Data chart, prior to the Industrial Revolution, emissions were very low. Growth in emissions was still slow until the mid-20th century. In 1950 the world emitted 6 billion tonnes of CO2.

By 1990 this had almost quadrupled, reaching more than 22 billion tonnes. Emissions have continued to grow rapidly, and we now emit more than 34 billion tonnes each year.

Emissions growth has slowed over the last few years as legislation has increased, but experts say they are yet to reach their peak.

The Battle Between Demand and ESG

Many industries and economies rely on hydrocarbon-derived products. Our everyday products, including medicine, clothing, toothpaste, and even solar panels start their lifecycle as unrefined petroleum. Demand for most of these items is not expected to drop with a growing population, while initiatives focusing on production from plant-based materials are still in their infancy.

Reducing emissions while ensuring an adequate supply of hydrocarbon derivatives is a complex issue for refinery operators and chemical producers. At a corporate level, Environmental, Social, and Corporate Governance (ESG) initiatives have been put in place to provide practical solutions to the issue of emissions, while continuing daily operations.

What is Thermal NOx?

In high temperature, gas-fired process heaters, including refinery fired heaters, steam methane reformers and steam crackers, the NOx emissions are mostly from Thermal NOx. These are formed when nitrogen and oxygen in the combustion air combine at high temperatures in flame combustion products.

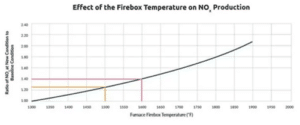

Effect of Firebox Temperature on NOx Production

The relationship between firebox temperature and NOx emission is shown in the chart below, which is extracted from API Standard 535.

What can Refineries do to Reduce CO2 and NOx Emissions?

IGS offers a range of solutions to improve fired heater efficiency and reduce emissions. One of these solutions is Cetek Ceramic Coatings. Cetek provides a durable, protective, thin-film layer on the outer surfaces of process tubes, which prevents oxidation, corrosion, and carburization of the metal and maintains the tube thermal conductivity coefficient close to new tube conditions.

Cetek coatings can be applied to the refractory, process tubes, or both, depending on the type of the fired heater and its design and operating parameters.

The result? Typical high emissivity ceramic coating applications to the tube and refractory surfaces show heat transfer efficiency benefits ranging from 5% to 15%, and a reduction in emissions of up to 25%.

READ: CO₂ Corrosion Prevention and Control in Oil and Gas Production

The Science Behind Ceramic Coatings and Surface Emissivity

In the radiant section, or primary reformer, much of the radiant energy from the flame/flue gases is transferred directly to the process/catalyst tubes; however, a significant proportion interacts with the refractory surfaces.

The mechanism of this interaction has a significant effect on the overall efficiency of radiant heat transfer. A major factor in determining radiant efficiency is the emissivity of the refractory surface.

At process heater operating temperatures, new ceramic fiber linings, for example, have emissivity values of around 0.4. Insulating Fire Brick (IFB) and castable materials have emissivity values around 0.6. These materials have been designed with structural considerations and insulating efficiency as the primary requirements. Therefore, they tend not to handle radiation in the most efficient way.

Cetek Ceramic Coatings, however, with emissivity values of above 0.9, has been designed specifically to supplement the radiation characteristics of the refractory surfaces.

It is important to understand how the emissivity property of a surface can affect the efficiency of heat transfer. There are two factors which need to be considered. The first is the spectral distribution of the radiation absorbed/emitted from a particular surface and the second is the value of the emissivity of that surface.

The Stephen Boltzman Equation Behind Fired Heater Surface Emissivity

The amount of heat, Q, radiated from a surface (area, A; temperature, T; emissivity, ε) is given by the following, well-known Stephan Bolzmann equation:

Q = AεσT4

Where σ is the Stephan Bolzmann constant.

Lobo & Evans and others extended the calculation with reference to fired heaters and a simplified equation would appear as:

QR = Aσ(T14-T24)/F

Where F = 1/ε1+{A1/A2}{(1/ε2)-1} for tubes of area A2, surface temperature T2 and emissivity ε2 which are inside an enclosure, area A1, with surface temperature T1 and emissivity ε1.

The effects of maximizing the emissivity ε1 of the enclosure are clear; there is a significant increase in radiant heat transfer to the tubes.

Convection Section Efficiency

While the Cetek coating improves the efficiency in the radiant section, robotic TubeTech™ cleaning can improve the efficiency of the convection section, further decreasing the fuel consumption leading to greater emissions reduction.

SCR Performance Optimization

Fired heaters that have an SCR can also benefit from screens and mixer plates, supplied by the SCR Solutions team. These solutions improve ammonia mixing and generate significant returns in terms of production and emissions reduction.

Conclusion

With increasing emissions legislation, and pressure on oil and gas facilities to reduce their carbon footprints, it is becoming increasingly important to ensure that mission-critical assets, particularly fired heaters, are performing efficiently and at full capacity.

There are several ways to reduce emissions and understanding the historical landscape as well as looking to the future of the industry, is crucial to making informed operational decisions on behalf of your facility.

More corrosion and erosion management articles from Integrated Global Services:

CO₂ Corrosion Prevention and Control in Oil and Gas Production

How to Prevent Microbially Influenced Corrosion (MIC) with On-Site Alloy Upgrade

Why is High Emissivity Coating Durability Important in Fired Heaters?

Strategies for Preventing Internal Pipeline Corrosion in the Energy Industry

Flue Gas Dew Point Corrosion Mitigation: Alloy Upgrading Techniques

Mitigating Metal Dusting Corrosion in Ammonia and Methanol Reformers

Combating Flow Accelerated Corrosion in Power Plants with IGS HVTS Technology

Why an Alloy Upgrade is the Best Solution to Crude Unit Overhead Corrosion Control

Protecting Hydropower Turbines from Corrosion with HVTS Coatings

Protecting Offshore Wind Turbines – Splash Zone Corrosion

The Critical Role of High Emissivity Coatings in Space Exploration

Organic Coatings in Pressure Vessels: Internal Coating Failure Analysis

How to Stop Corrosion on Your Refinery Distillation Column

Causes of Boiler Corrosion and Benefits of Boiler Tube Coating

5 Common Causes of Refractory Failure and How to Fix Them

Boiler Tube Leaks Prevented with Proactive Maintenance

A Guide to Amine Stress Corrosion Cracking in Oil & Gas Processing