Heat Transfer Efficiency Solutions

TubeTech™ Fouling Removal Services

For more than 30 years, TubeTech™ have been pioneers in solving the toughest fouling challenges in the fired heater convection section, heat exchanger bundles, and texas towers.

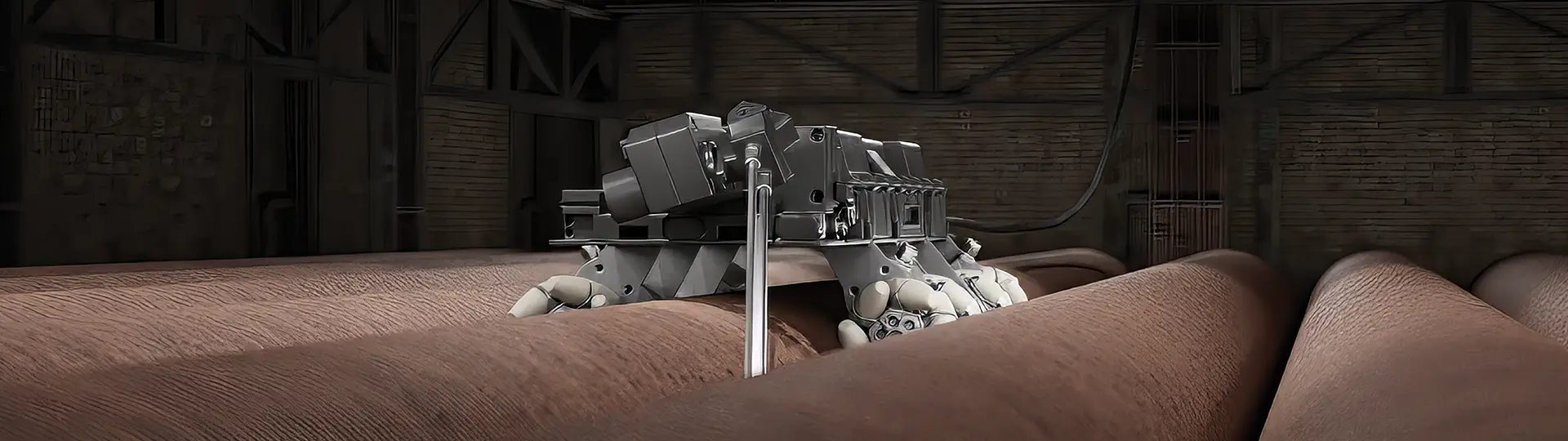

TubeTech’s patented robotic and remote fouling removal technologies remove over 90% of fouling, even on the most fouled assets.

With multi-million R&D investment, TubeTech™ have developed a reputation for leading innovation. TubeTech™ have invested heavily in developing equipment and processes that make fouling removal safer and more thorough.

With bases in Europe, the USA, Middle East and Asia, TubeTech’s experienced technicians are available to deliver local support and rapid mobilization anywhere in the world. TubeTech’s trademark bespoke approach to each job significantly improves asset life, restores performance, and boosts productivity, with minimum disruption and maximum results.

Applications Across Key Process Facilities

TubeTech™ solutions are trusted across a wide range of high-temperature processing environments, including:

-

Olefins Facilities

Ethylene, PDH, Styrene, EDC/VCM -

Syngas Facilities

Ammonia, Methanol, Hydrogen -

Refining Facilities

Fired heaters, WHRUs, fin-fans in FCC units, reformers, hydrocrackers -

Chemical Facilities

High-temperature process units in continuous and batch operations

Before Finned Tube Fouling Removal Services

After Finned Tube Fouling Removal Services

TubeTech™ Fouling Removal Services

Heat Exchanger Fouling Removal Services:

- Shell and Tube Heat Exchanger Fouling Removal

- Fired Heater Furnace Fouling Removal

- Texas Tower (VCFE) Fouling Removal

- Twisted Tube Heat Exchanger Fouling Removal

- U-Tube (Hairpin) Heat Exchanger Fouling Removal

Air Cooled Condenser Fouling Removal (ACC)

Fouling Removal for Inspection:

I’m here to help

Scott Donson

IGS Subject Matter Expert

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.