The Benefits of Online Refractory Repair

The fast, safe, and reliable way to repair fired heater refractory damage online. Avoid expensive emergency shutdowns to make a conventional repair. Continue full production until the next planned turnaround. Hot-tek™ teams, with more than 20 years of online work experience, can tackle most refractory lining problems.

What are the Benefits of Hot-tek™ Refractory Repair?

1. Multiple Hot Repair Technologies Available

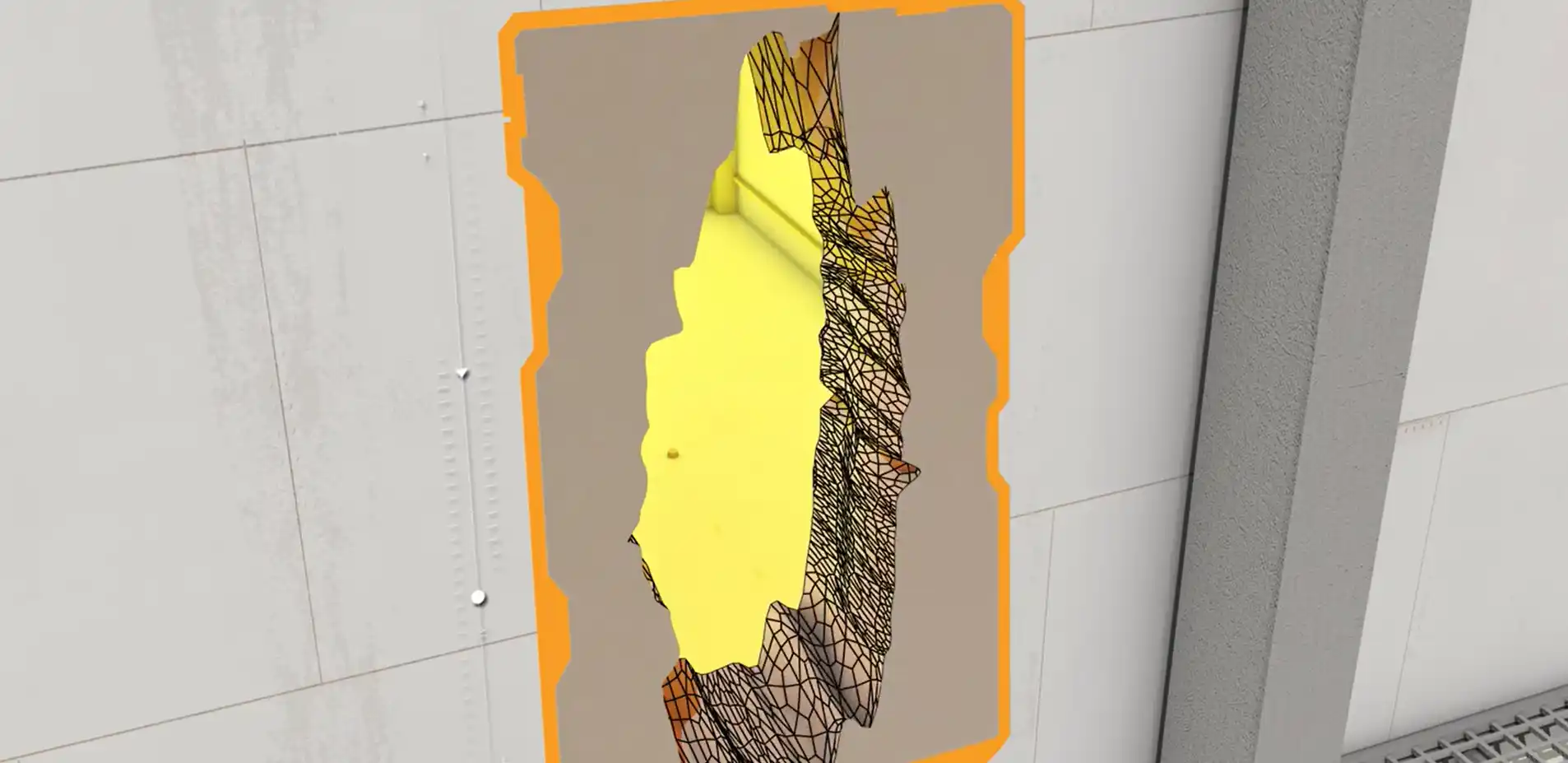

Existing access points in the heater steel shell may be used, or access is made at the point of damage to insert specially designed components to support the repair material.

2. Fast Payback

Quick ROI compared to the costs associated with conventional repairs which require the heater be shutdown.

3. Maintain Production & Avoid Costly Shutdowns

Hot-tek™ safely repairs refractory whilst the heater is online, with no interruption to production, avoiding the need for an emergency shutdown to make a conventional repair.

4. Rapid Worldwide Mobilization

With Hot-tek™ technicians and equipment strategically placed worldwide, we can mobilise rapidly to meet your requirements.

Talk to us about a Free Technical Evaluation.

“IGS worked efficiently and was very timely, which was appreciated given the urgency of our situation. They were very helpful with any questions that we had.”

Hydrogen Plant in California