Hot Tube Descaling

You May Need Hot Tube Descaling if Your Radiant Section Hits Design Limits, Such as Bridgewall Temperature.

Increase of Bridgewall Temperature can be a symptom of excessive fouling of the radiant tubes. These steel alloy tubes tend to oxidize under operating conditions. Layers of scale grow with time to a degree that it insulate the tube fire side from the radiant heat. It is even more problematic if there are several years until the next scheduled shut down.

Hot Tube Descaling

Hot-tek‘s patented Hot Tube Descaling Process removes radiant section process tube fireside scale & fouling during furnace operation. Our hot tube descaling process uses proprietary water-cooled lances. We ensure safe and continuous scale removal for maximum cleaning of the tubes while the heater continues to function normally. The process utilizes consumable abrasive media resulting in no increase in opacity.

In some applications, we use Hot-tek’s Lancescope™ system to see hard to reach areas. We also have the capability to safely create engineered access ports. These ports can be used to facilitate the hot tube defouling process.

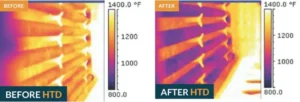

Typical results of the hot tube descaling process include bridgewall temperature reduction of 50°F (10°C) to 100°F (38°C). Dozens of our customers note rapid payback from using this service. As a longer-term solution, we provide tube coating service, that stops tube oxidation and scaling for 8-10 years.

Before & After Hot Tube Descaling

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.