Hot Refractory Repair Services

Hot Spot Repair in Live Heaters

Hot spots in the shell of the fired heater limit capacity and can cause a forced shutdown. Our experienced global team mobilizes at short notice to repair refractory online.

What is Refractory Failure?

The refractory may fail prematurely due to the failure of support/anchors holding the lining in place or an operational upset.

In these cases, the operator must decide whether to interrupt production by bringing the heater off-line to make a conventional repair or continue at reduced capacity until the next scheduled shutdown.

Alternatively, an online refractory repair may be made by Hot-tek™, where there is no need to bring the heater off-line and production will not be interrupted or limited in capacity.

SEE HOW IT’S DONE: 3D Overview of Fired Heater Hot Spot Repair

Hot Spot Repair Procedure Online

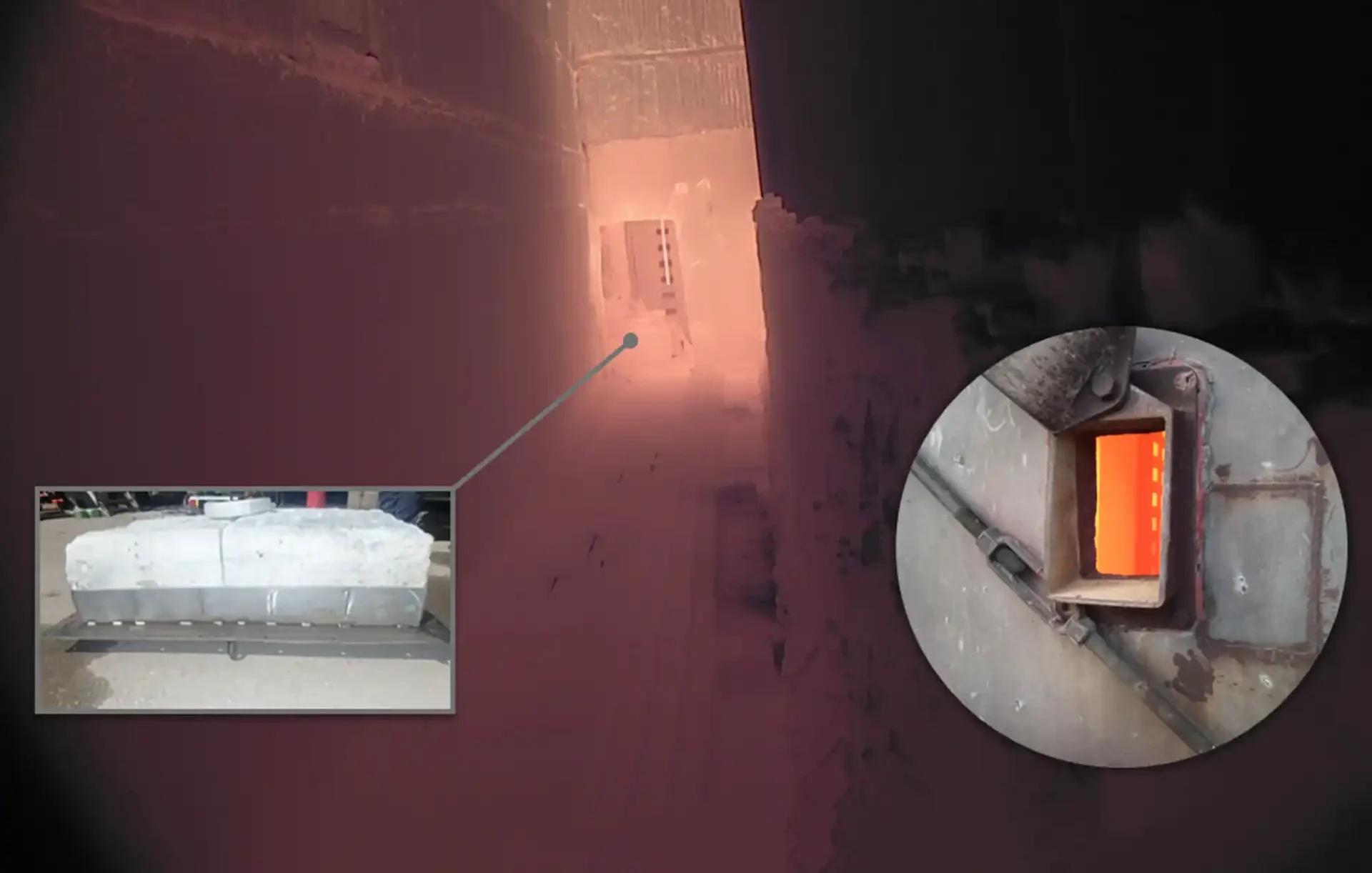

IGS has developed a proprietary Hot-tek™ solution for online hot spot repair. The IGS team creates minimal openings to insert specially designed components and repair material, delivering a semi-permanent repair lasting at least until the next planned turnaround.

WATCH VIDEO: How Long Does Hot Convection Cleaning Take?

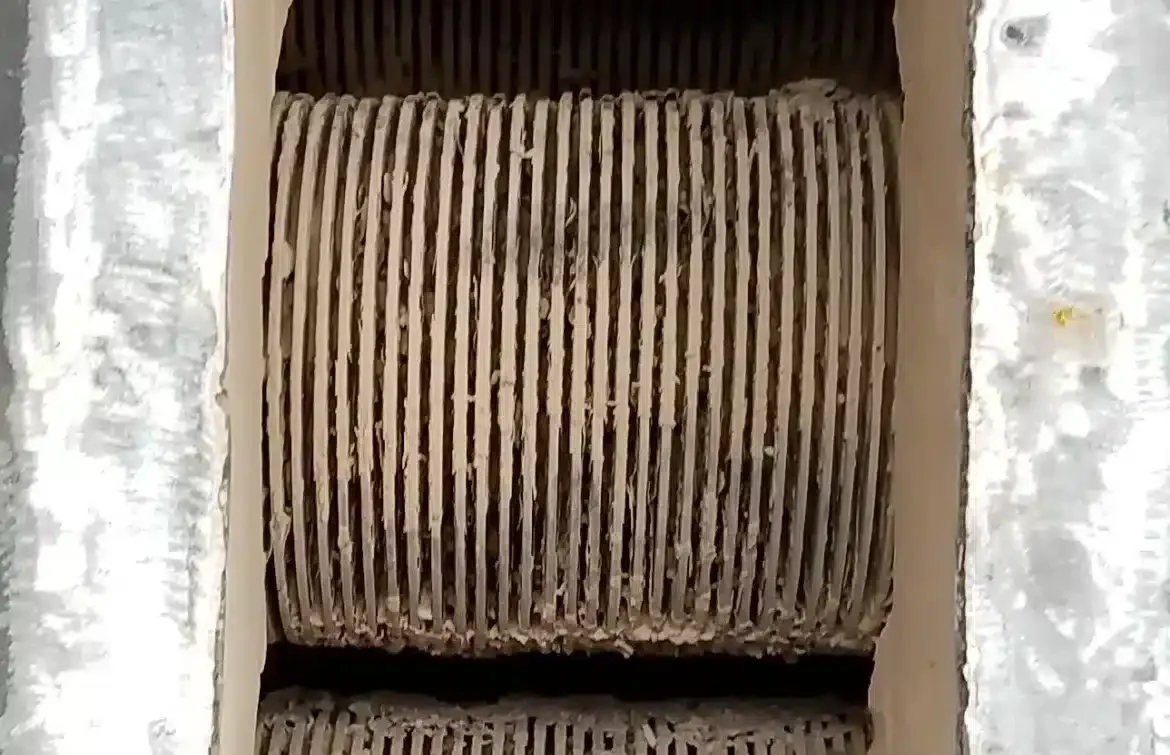

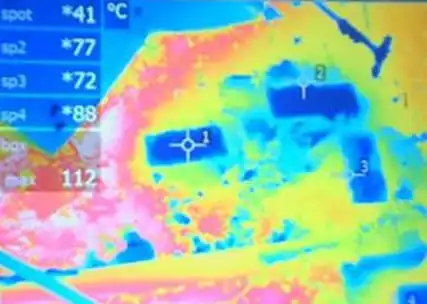

Hot spot before Hot-tek™ Hot Refractory Repair

This before and after demonstrates the effectiveness of the IGS Hot-tek Hot Refractory Repair service for fixing hot spots to keep key production assets online.

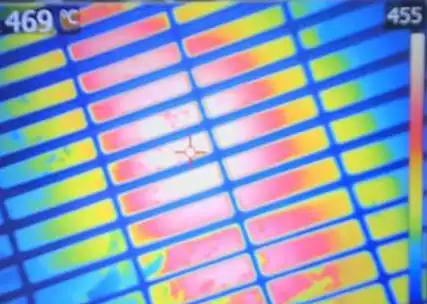

Hot spot after Hot-tek™ Hot Refractory Repair

IGS Hot-tek online hot spot repair service enabled the client to avoid shutdown, solving the problem while keeping the asset online.

Testimonial

I wanted to take a moment to express my sincere gratitude for the great job you and your team did on our Furnace roof while the furnace was still online. This was the first time we attempted this type of repair in our plant.

We were impressed by your team’s level of skill, precision, and professionalism. At first, we were hesitant about the safety and the method of repair while the furnace was online, but your team’s experience and expertise made the process seamless and efficient.

The repair was completed successfully without disrupting our production schedule, which is a testament to your team’s hard work and dedication. I also appreciate your patience and willingness to answer our questions and concerns throughout the process. Your guidance was invaluable and helped us understand the repair process better.

– Head of Maintenance, Oman Oil Industry Company

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.