Power

Boiler Reliability and Plant Availability

IGS is revolutionizing the coal power industry with our advanced boiler cladding solutions. We combine over three decades of expertise with innovative technology to tackle the biggest challenges in coal-fired boilers.

Coal and Lignite Fueled

Boiler Cladding

Coal remains a cornerstone in the global energy landscape, powering the majority of the world’s electricity generation. Despite the shift towards renewable sources, projections by the International Energy Agency (IEA) indicate that fossil fuels, including coal, will continue to dominate, accounting for over 70% of the energy market by 2035. Addressing Boiler Challenges: Erosion and Corrosion Solutions. Coal-fired boilers are susceptible to erosion, corrosion, or both, leading to significant damage. Among the most prevalent boiler types are fluidized bed boilers and pulverized coal-fired boilers. IGS’s expertise encompasses an extensive range of services for CFB, Pulverized coal, FGD Units, Economizers, Soot blowers, and SCRs. With our global experience, we likely have a proven boiler cladding solution tailored to your needs.

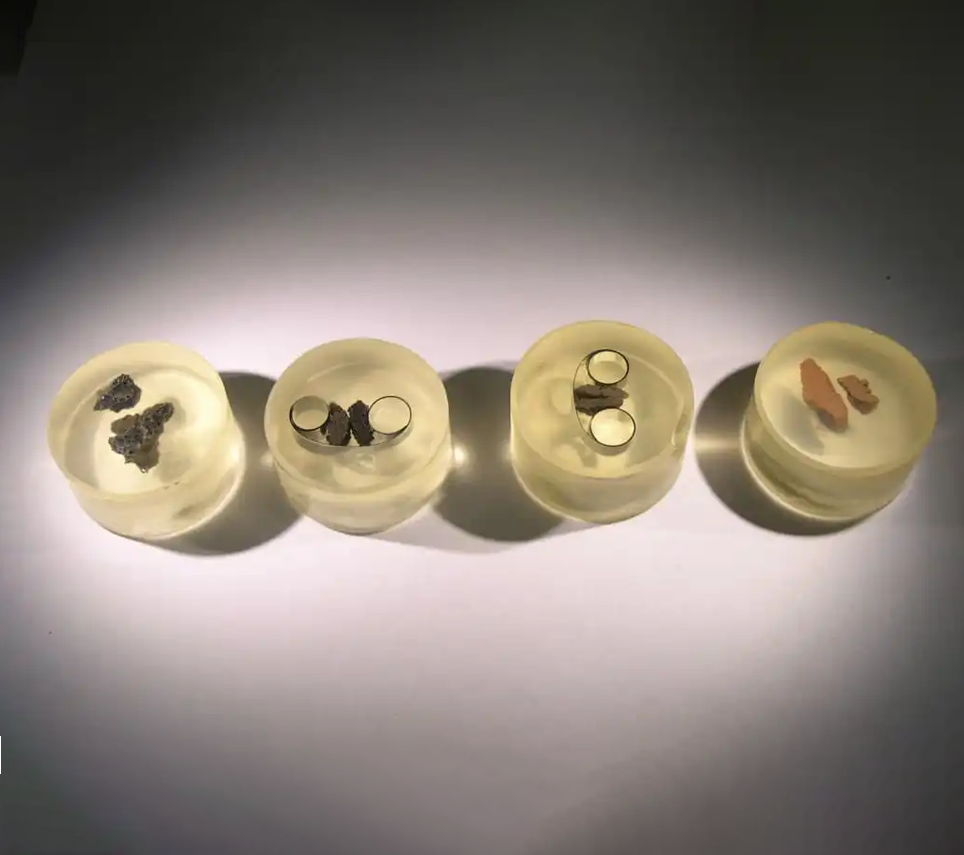

Image: Image: “Boiler Ash Analysis: Paving the Way for Optimal Cladding

Corrosion of Coal-Fired Boilers

Tackling CFB Boiler Fireside Corrosion-Erosion

CFB boilers operate by combusting fuel in a fluidized bed of non-combustible particles. As these bed material particles recirculate in the furnace, they cause wastage of the furnace waterwall and evaporator panels. This corrosion-erosion mechanism is an unavoidable consequence of this boiler design. The wastage develops frequently at refractory to waterwall/evaporator interface, field weld joints in the furnace, and around the cyclone inlets. We provide HVTS metal-based coatings to mitigate corrosion-erosion of waterwall panels of circulating fluidized

bed boilers.

Outside of the tube wastage, several components require regular maintenance to keep the units running optimally. These include vortex finders, loop seals, expansion joints, bed nozzles,

and tube replacement.

For more information on our mechanical and refractory solutions, click here.

Pulverized Coal Boilers’ Metal Wastage

Pulverized Coal (PC) Boilers generate thermal energy by burning pulverized coal injected through a combustion air stream to the burners in the firebox. As this coal combusts, compounds such as Sulfur react with the surrounding iron-based materials to cause metal wastage. Common issues include:

- Boiler waterwall fireside corrosion

- Lower slope erosion

- Upper nose arch erosion

- Sootblower erosion

- Corrosion assisted thermal fatigue

- Fouling/slag build-up

With our metal alloy boiler cladding, we prevent fireside corrosion of PC-fired boilers, as well as erosion and thermal fatigue.

The Comprehensive IGS

Boiler Cladding Solution

For each boiler component, IGS offers an array of services – Mechanical and Refractory Services, High Velocity Thermal Spray, Catalyst Protection Options, and boiler deslagging technology. Our solutions are not just about extending the life of your assets; they’re about optimizing operational costs and enhancing asset value. The synergy of material quality, advanced application technology, and skilled labor is key to our success in boiler protection.

- Customized Solutions and Skilled Maintenance

We tailor our HVTS boiler cladding to meet specific erosion and

corrosion requirements, ensuring it aligns with your unique application

and performance goals. Our maintenance teams, comprising highly skilled professionals, focus on key power boiler equipment, offering both mechanical and refractory services. - SCR Solutions and Protection

IGS’s SCR Solutions team has pioneered patented technology to shield

SCRs from large particle ash. Combined with air cannons, sonic horns,

and secondary screens, we guarantee up to 95% SCR cleanliness. - Ceramic Technology for Anti-Slagging

IGS’s ceramic technology line offers advanced anti-slagging solutions that reduce flue exit gas temperature (FEGT) and improve boiler heat rate.

Flue Gas Desulfurization (FGD)

Economizer

We provide corrosion-resistant cladding for boiler economizer tubes.

Sootblower Erosion

Our highly erosion-resistant materials and Cetek® anti-slagging technology address sootblowing environments in pulverized coal boilers. Utilizing our experience in high erosion applications, we spray proprietary materials on-site that withstand the aggressive conditions associated with air and steam soot-blowing.

Selective Catalyst Reactor (SCR)

IGS designs, engineers, manufactures the longest-lasting large particle ash (LPA, or “popcorn ash”) filtration systems in the world. Typical filtration screens protecting catalysts within SCR systems have proven to be short-lived and unreliable, resulting in frequent clogging of the catalyst with LPA, decreasing NOx reduction performance. In contrast, IGS’s patent-pending NoNOx™ Components have been in service for years in some of the most aggressively run SCR systems in the world, having maximized catalyst maintenance cycles, reducing the likelihood of unplanned downtime, and significantly reducing the lifetime cost of SCR systems.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.